Solids valve: Segmented design features for efficient handling

tim2024-02-05T11:19:00+00:00Handling solid materials efficiently and safely is a critical requirement in various industries, from pharmaceuticals to minerals. At Techno-G, we specialize in providing advanced solutions for these challenges, particularly through our high-quality ball segment valves. These valves, designed according to PED guidelines, are not only created for the efficient handling of fine solid materials but are also equipped with features like an inflatable seal, which optimizes pressure management and enhances reliability. In this article, we explore the key features of segmented solids valves and their impact on solid handling.

Table of Contents

Understanding ball segment valves

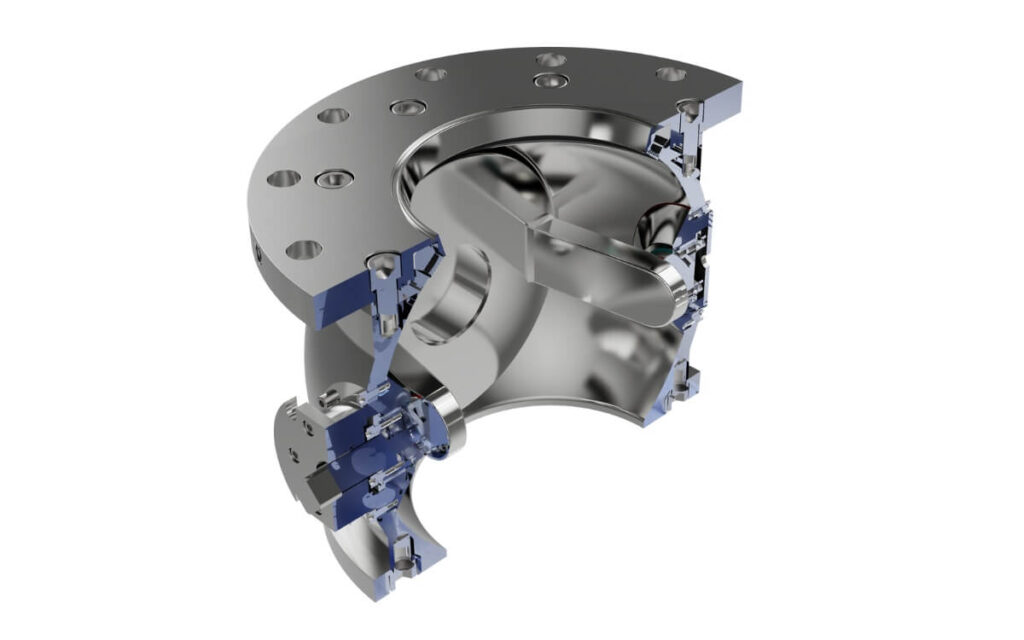

Ball segment valves stand out in their ability to handle challenging industrial processes, especially in the management of solids. Featuring a unique segmented design, these solids valves ensure precise control and effective sealing, making them a key component in various sectors.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

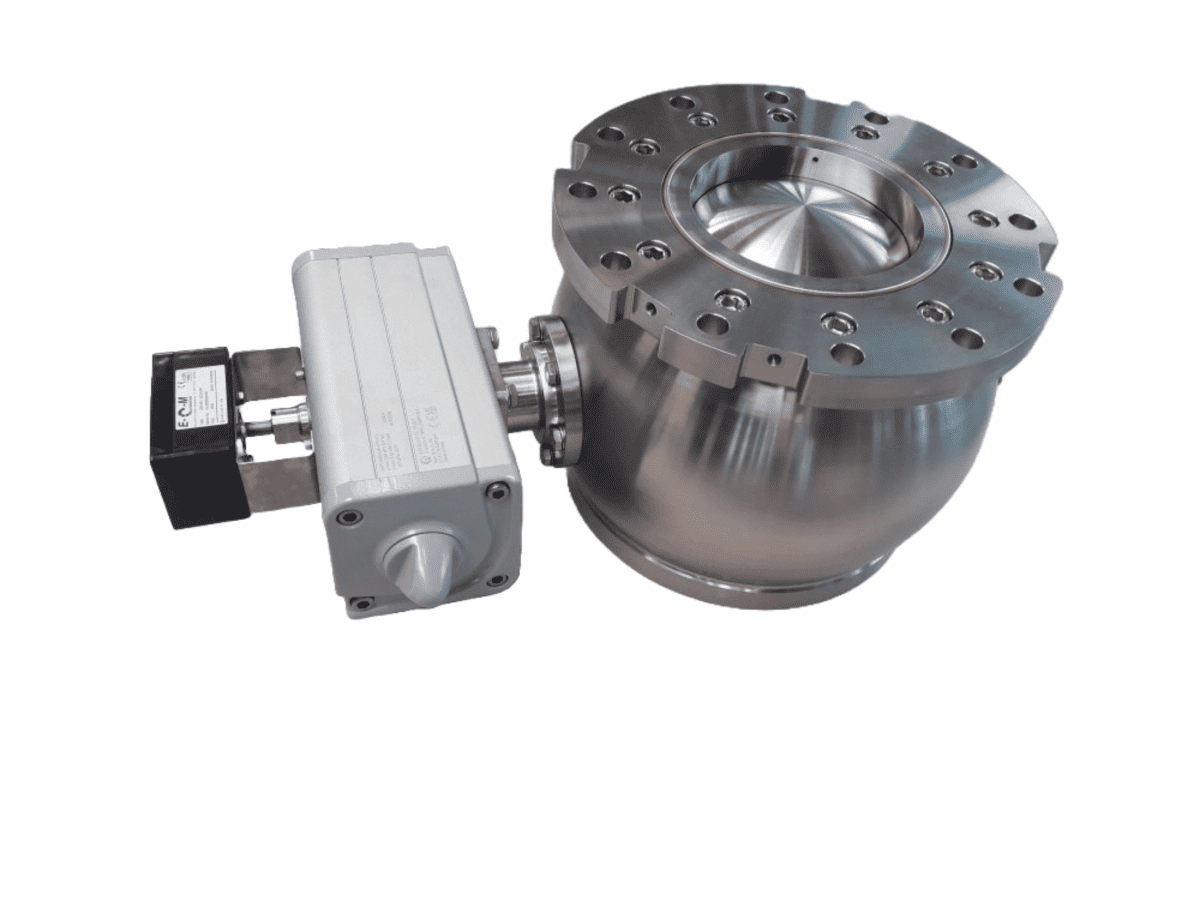

Advanced products with special geometry

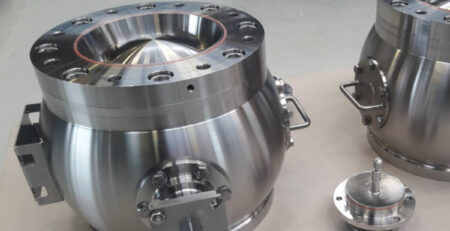

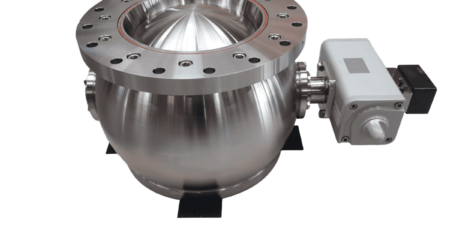

Our ball segment valves are crafted with a compact design that sets them apart. The ball segment large open bore flange opening allows for smooth operation, even with abrasive products or in challenging service conditions. This design minimizes body wall erosion, a common issue in solids handling.

Customized solutions for diverse applications

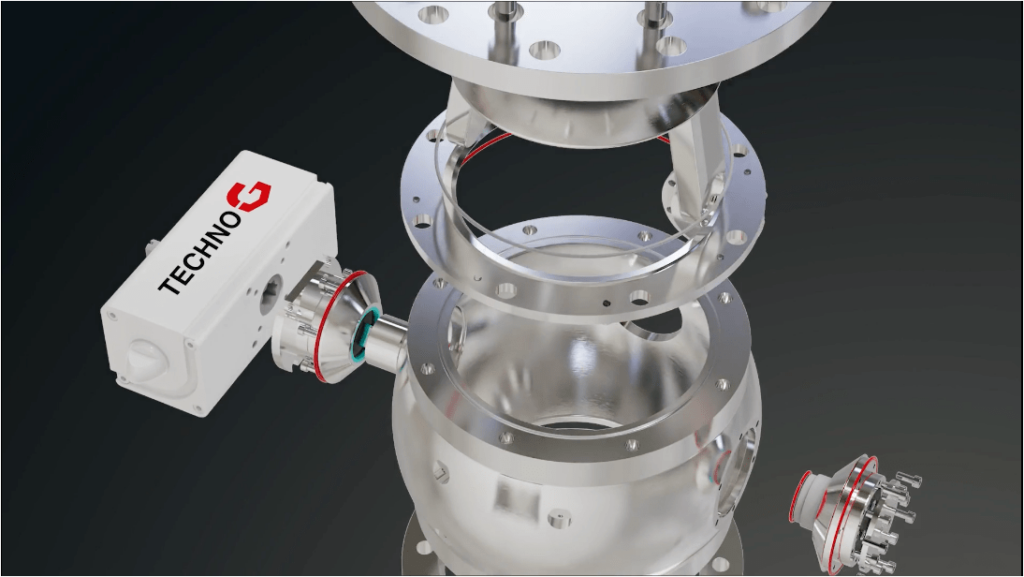

Our solids valve (segmented) caters to a breadth of industries. Whether it’s for chemical processing or food industries, they are tailored to meet application-specific requirements even in corrosive hazardous environments. This customization ranges from material specifications to control mechanisms, ensuring a perfect fit for your unique demands.

Innovative features for reliable operation

The innovative features of modern solids handling equipment are key to their reliable operation. These include precision-engineered components that ensure a tight seal, even under varying pressure conditions, and adaptable designs that caters to a range of industrial needs. The inflatable seal, for instance, provides a bi-directional vacuum-tight shutoff, essential for maintaining the purity and integrity of the processed solids. Such features significantly reduce maintenance needs and enhance overall efficiency. Durability is also a focus, with materials chosen for their ability to withstand corrosive and erosive substances and high-pressure environments. These advancements not only streamline operations but also contribute to long-term cost savings, demonstrating the importance of innovation in achieving both operational excellence and economic efficiency in solids handling.

Download our free whitepaper

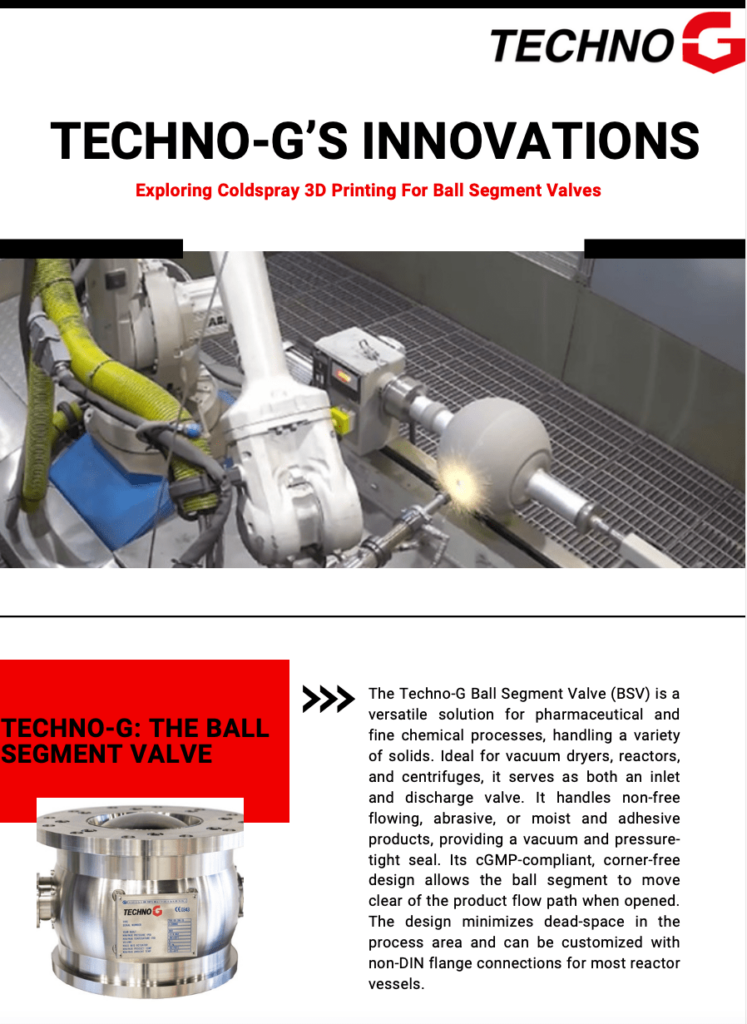

"Exploring Coldspray 3D Printing For Ball Segment Valves"

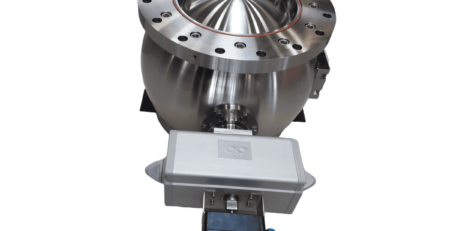

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

The impact on solid handling

The features of ball segment valves directly impact their effectiveness in handling solids. The design and construction of these valves ensure they can handle a wide variety of solids, from granules to powders, without clogging or causing damage to the materials.

Non-clogging flow control

One of the significant challenges in solids handling is avoiding clogs and blockages. The full-bore design of our valves, with features like a central flow path and smooth bore through material flow, addresses this issue.

Application in a multitude of industries

The versatility of solids valves (segmented) makes them suitable for a multitude of applications. From handling abrasive applications in the mining sector to dealing with delicate food-grade applications in the food processing industry, these valves are designed to perform reliably under various conditions.

Enhancing efficiency and safety

With features like adjustable sealing and hygienic design, our valves not only enhance efficiency in material handling but also bolster safety. This is especially crucial in industries where maintaining product integrity and operator safety is paramount.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Customization and range of options

Customization is key in the world of industrial valves, especially when it comes to handling diverse solid materials. At Techno-G, we understand this necessity and offer a range of size options and special executions to ensure that our valves meet the exact needs of each application. This adaptability extends to various aspects of valve design, including connection types, body materials, and control options. Think of brackets for attaching pneumatic devices, PTFE Lining, and Specialty coated valve head designs.

Addressing specific industry challenges

Each industry faces its own set of challenges when it comes to handling solids. For example, in the food industry, maintaining cleanliness and preventing contamination are paramount. Similarly, in the chemical industry, dealing with corrosive materials requires valves with exceptional corrosion resistance and robust construction.

Technological innovation and quality assurance

Each industry faces its own set of challenges when it comes to handling solids. For example, in the food industry, maintaining cleanliness and preventing contamination are paramount. Our valves are designed with features like clean sealing surfaces(onzin), which are crucial for food-grade applications. Similarly, in the chemical industry, dealing with corrosive materials requires valves with exceptional corrosion resistance and robust construction.

Advanced control systems

For applications requiring precise control, our valves are compatible with sophisticated control systems. We offer options like pneumatic actuators and control boxes, which allow for precise manipulation of flow rates and pressures. This is especially important in industries where the slightest variance in control can have significant consequences and in which 100% reliability is of utmost importance.

Long-term benefits and operational efficiency

Investing in high-quality ball segment valves from Techno-G is not just about meeting immediate needs; it’s about ensuring long-term operational efficiency and cost-effectiveness. Our valves are designed to minimize operational costs by reducing maintenance needs and prolonging service life. The use of durable materials and advanced coatings reduces the likelihood of damaged seats and wear, translating to fewer shutdowns and replacements over the valve’s lifespan. In essence, our segmented ball valves not only meet the current demands of solid handling but also pave the way for future advancements in industrial valve technology.