Why is a pressurized segment valve for solids handling essential?

tim2023-12-08T15:04:57+00:00At Techno-G, our expertise lies in crafting Ball Segment Valves, tailored for efficient handling of fine solids. This article explores the critical role of pressurized segment valves in industrial applications, particularly for solid materials. We’ll discuss the necessity of these valves and highlight the distinct advantages of our products, including their innovative inflatable seals, illustrating why they are not just beneficial but essential in various industrial processes.

The essential function of segment valves for solids handling

Handling solids, whether in the form of bulk materials, powders, or granules, requires precision and control. Valves are needed for ensuring accurate flow control and management of these materials. From industries like pharmaceuticals and food production to chemicals and minerals processing, the demand for reliable valve systems is universal.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Key features of effective ball segment valves

- Precise flow regulation: Essential for maintaining the integrity of the material being processed.

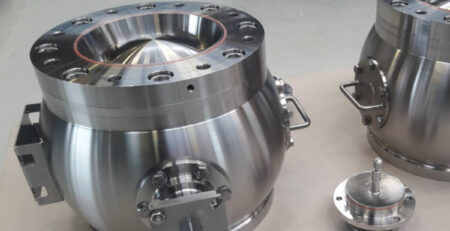

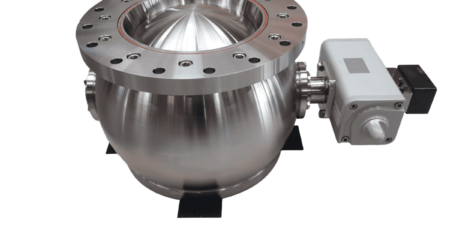

- Durability under pressure: Solid materials, particularly abrasive ones, can cause significant wear and tear on valve components. At Techno-G, our valves are constructed from robust materials like stainless steel or 3D-printed Titanium, ensuring a long service life even under challenging conditions.

- Minimal dead space: Ensuring the complete discharge of materials is crucial. Ball segment valves with minimal dead space prevent material build-up and contamination.

- Customization options: Every application has unique requirements. Our valves, for example, are available in sizes ranging from DN100 up to DN500 to suit various needs.

- Advanced sealing technology: The inflatable seal, a standout feature in our valves, provides an airtight closure, ensuring zero leakage and maintaining the purity of the material.

Applications and industries

Valves for handling solids are important in a variety of industries. They help keep things safe and clean in industries such as:

- Pharmaceutical sector: Ensures safe and hygienic handling of powders and granules.

- Food industry: Critical for maintaining quality and safety standards.

- Chemical industry: Benefits from durability and robustness, especially with abrasive or corrosive materials.

- Mineral industry: Relies on the valves’ durability and robustness for handling challenging materials.

- Other industries: Various applications in additional sectors, utilizing the valves for their specific material handling needs.

Download our free whitepaper

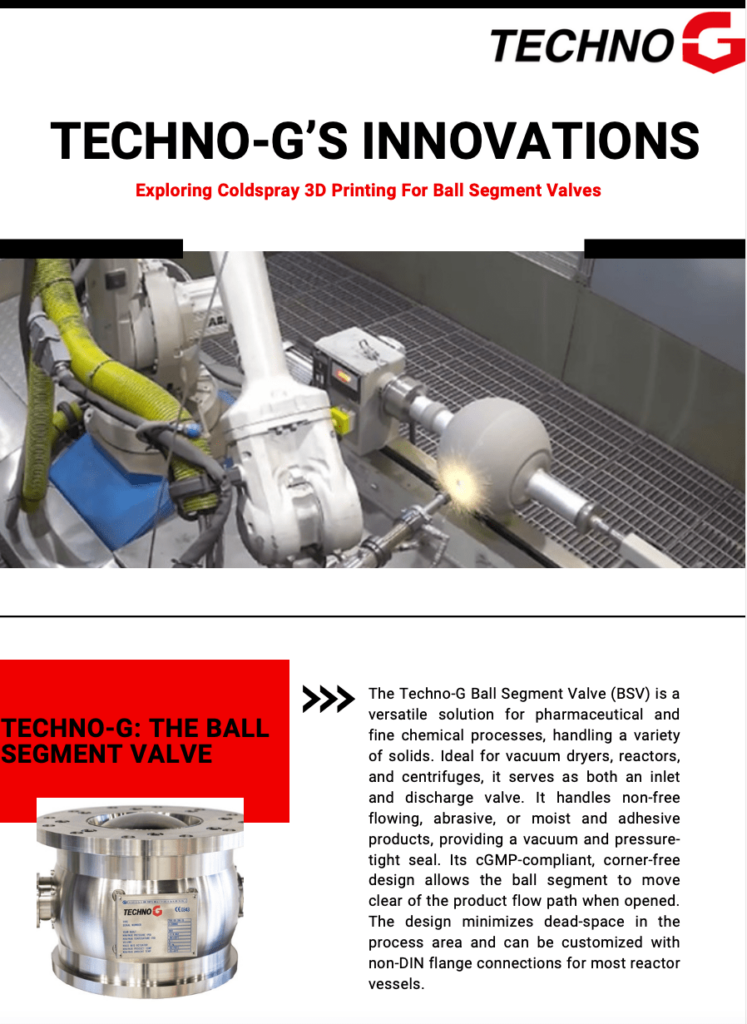

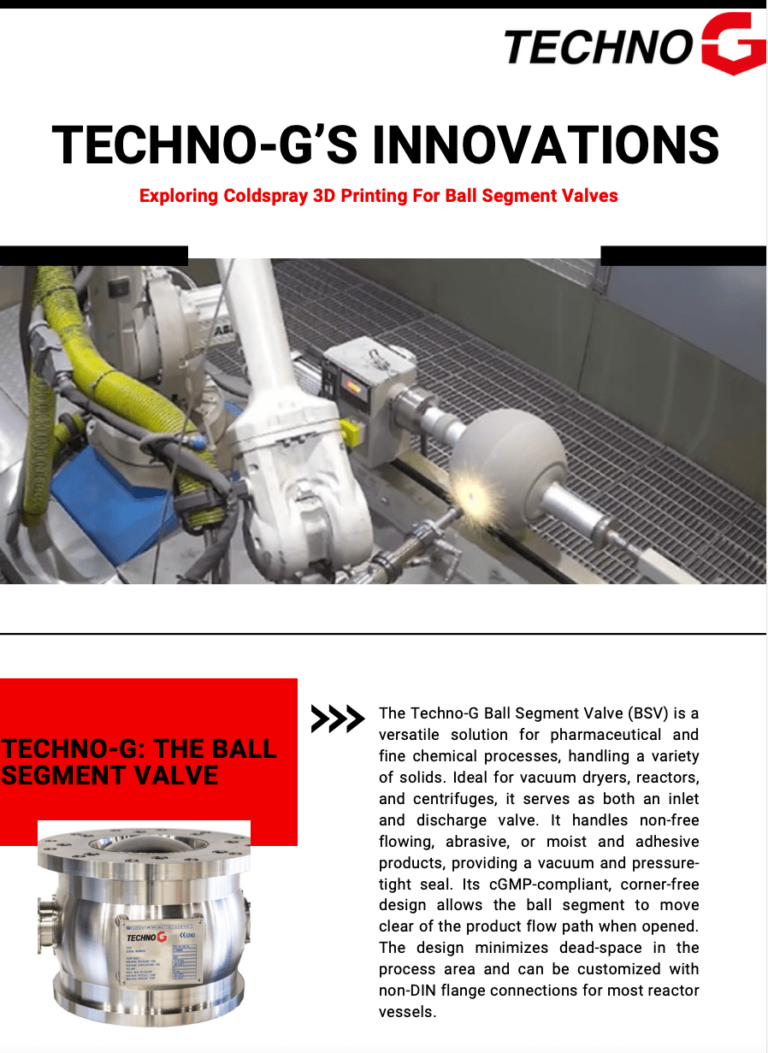

"Exploring Coldspray 3D Printing For Ball Segment Valves"

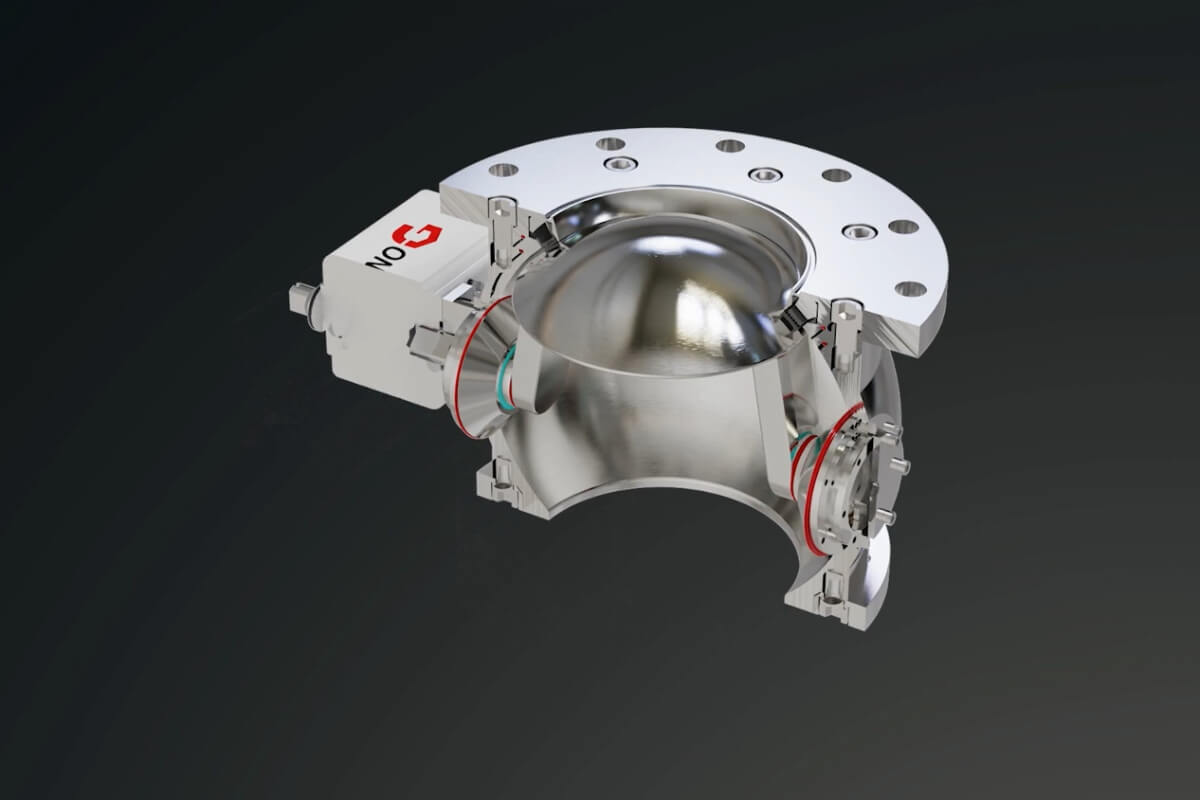

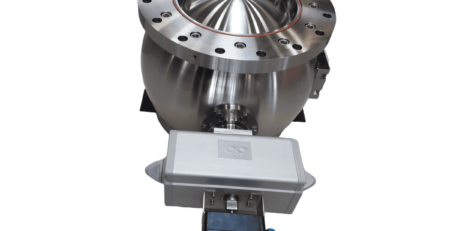

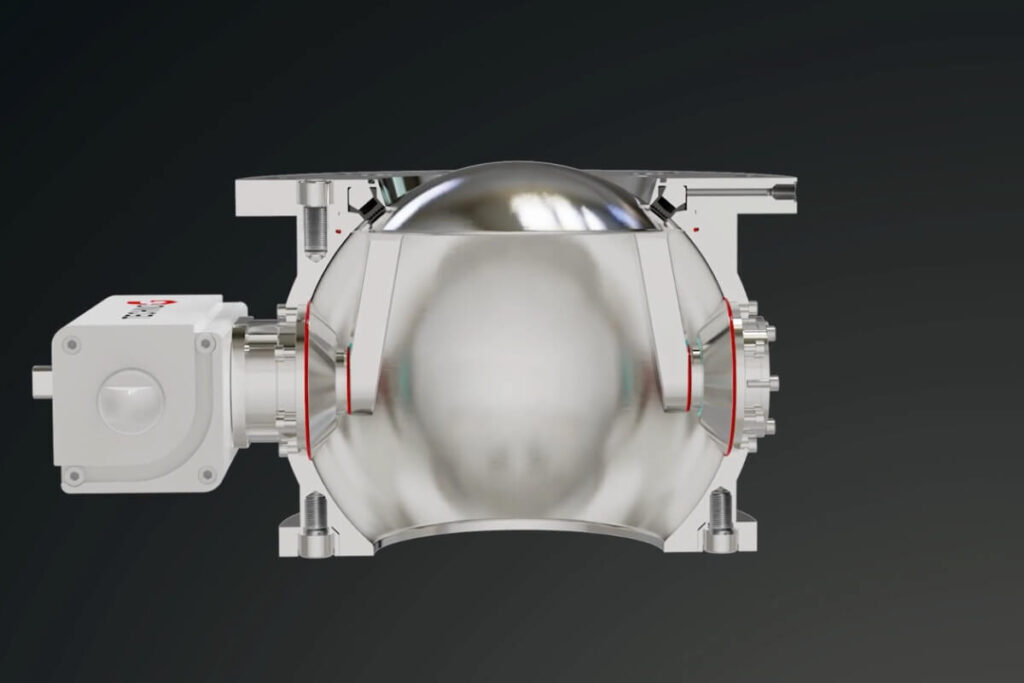

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Techno-G's approach to solids handling

Our approach at Techno-G is to provide solutions that are not just effective but also innovative. We understand that the handling of solids requires more than just basic flow control – it demands precision, reliability, and versatility.

- Innovative design

Our Ball Segment Valves are not just another valve in the market. They are the culmination of extensive research and development, aimed at addressing common issues in solids handling, like abrasion damage, product flow regulation difficulties, and maintenance challenges.

- The inflatable seal advantage

One of the defining features of our valves is the innovative inflatable seal. This seal provides an unprecedented level of airtight closure, essential for maintaining pressure conditions and preventing contamination. The details of this technology can be explored in our Exploded view.

- Customization

We understand that one size does not fit all in industrial applications. That’s why we offer a range of customization options, detailed in our Special executions page.

- Quality and reliability

Quality control is not just a process but a commitment at Techno-G. Our valves undergo rigorous testing and quality checks, ensuring they meet the highest standards. Our dedication to quality and reliability is detailed in our Quality Control and Certifications section.

Tailored solutions for diverse industries

Our valves are versatile, catering to a wide range of industries. In the pharmaceutical industry, precision and contamination control are paramount. Our valves, with their tight sealing and minimal dead space, excel in these environments. The food industry benefits similarly, especially considering our valves’ ability to handle various particle sizes and maintain product integrity, as seen in our Food Industry Applications.

In more abrasive sectors like minerals and metals processing, our valves demonstrate exceptional durability and resistance to wear. This is particularly important in applications with elevated temperature or abrasive materials, where our valves’ robust construction comes to the fore.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

A closer look: Case studies and technical insights

- Pharmaceutical industry: Ball segment valves have been instrumental in ensuring hygienic conditions and precise control in pharmaceutical manufacturing. They have been used in processes involving active pharmaceutical ingredients (APIs), where preventing contamination is critical. Their reliable sealing and contamination-free operation make them ideal for tablet compression and powder handling applications.

- Fine chemicals: With our unwavering commitment to innovation and deep industry expertise, we deliver comprehensive solutions that optimize production processes, ensure exceptional quality, and meet stringent regulatory requirements. As your trusted partner, Techno-G empowers you to achieve success and excellence in fine chemicals and API manufacturing.

- Chemical processing: Our valves have shown resilience in environments with aggressive or corrosive materials. They’ve been successfully used in chemical plants dealing with acids, alkalis, and solvents, providing consistent performance and maintaining material integrity. Their robust construction ensures long-term reliability even in harsh chemical processing scenarios.

Next steps

Techno-G’s Ball Segment Valves, a range of innovative designed products, represent reliability in fine chemical and bulk solid handling industries. With our commitment to quality, customization, and advanced technology, we provide solutions that go beyond mere functionality, offering efficiency, safety, and durability. Stay tuned for more insights from Techno-G, where we blend innovation with reliability to revolutionize fine chemical and solids handling.