How a pressure segment valve regulate pressure in industrial applications

tim2024-02-05T12:28:11+00:00Pressure Segment Valves play an important role in managing and regulating pressure in countless industrial settings. These valves are specifically designed for efficient handling of fine solid materials and are, if talking about Techno-G, equipped with an innovative inflatable seal for optimal pressure management. Within this article, we delve into the functioning of valves, their applications, and their advantages in different industries.

Table of Contents

Understanding the basics

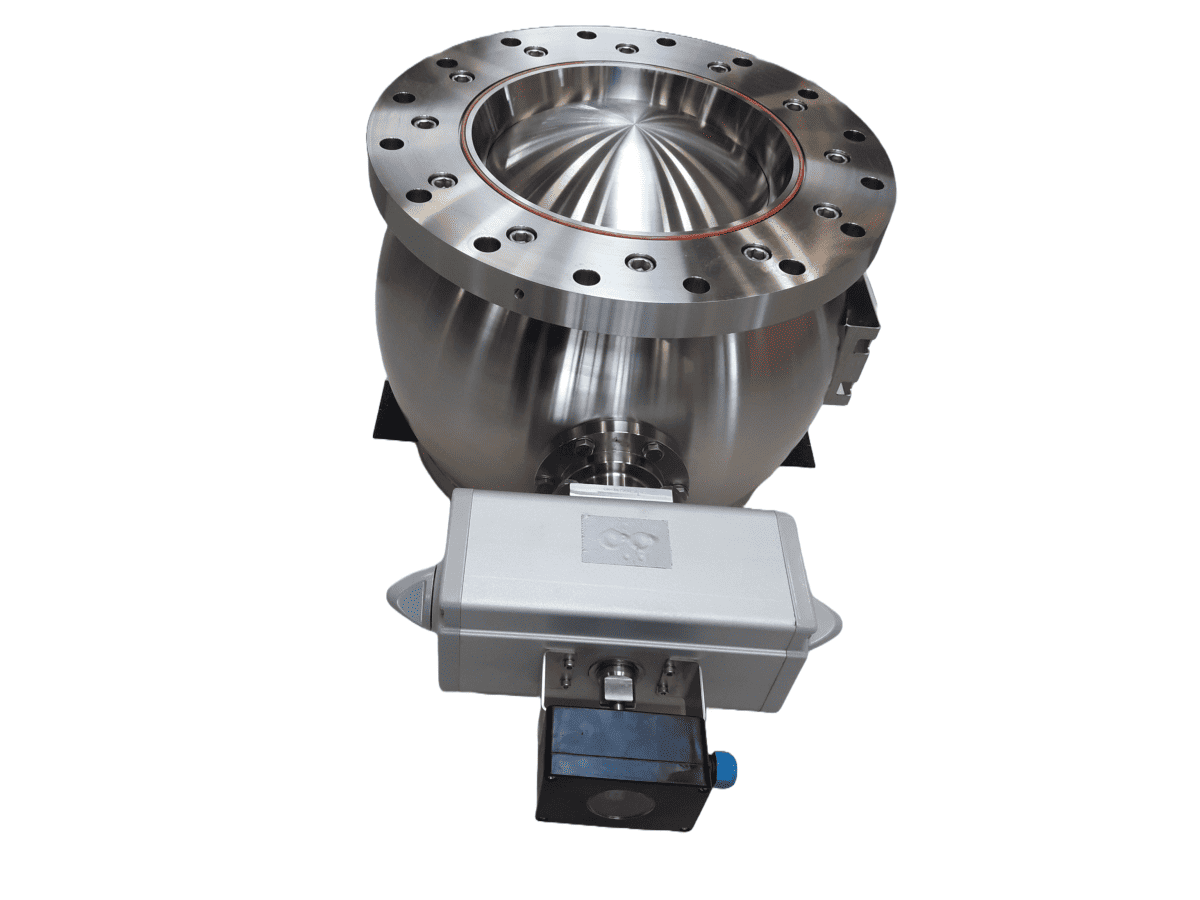

A pressure segment valve is an integral component in controlling and maintaining pressure in various industrial processes. At its core, it operates by adjusting the flow of materials – liquids, gases, or solids – through a system. In our case, Techno-G provides ball segment valves optimized for handling solids. This regulation is crucial for ensuring both the efficiency and safety of industrial operations. These valves are designed with precision, allowing for the modulation of pressure to suit specific application needs. From managing flow in pharmaceutical manufacturing to controlling pressure in food processing, pressure segment valves are essential for a wide range of industrial applications, highlighting their versatility and importance in modern industry.

The role of the ball and body design

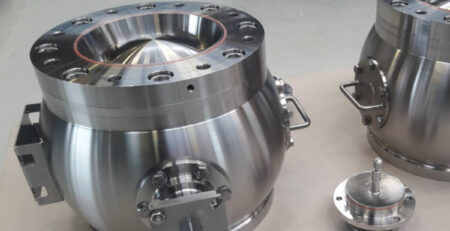

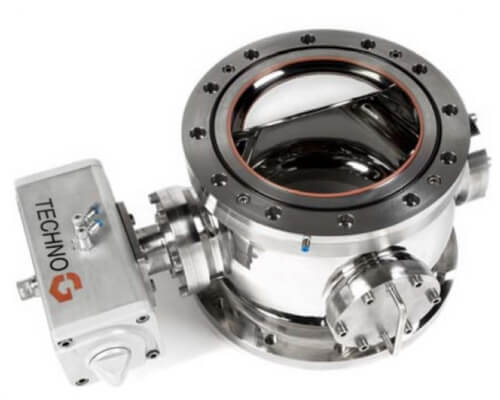

The ball segment, when correctly aligned, offers a wide opening and sufficient space for material flow. The design of the ball to body contact is crucial in ensuring a non-clogging flow control, especially in applications dealing with harsh environments or abrasive solids. The valve body is often made from robust materials like stainless steel, Titanium or Hastelloy, providing necessary strength, corrosion and erosion resistance.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Sealing mechanism

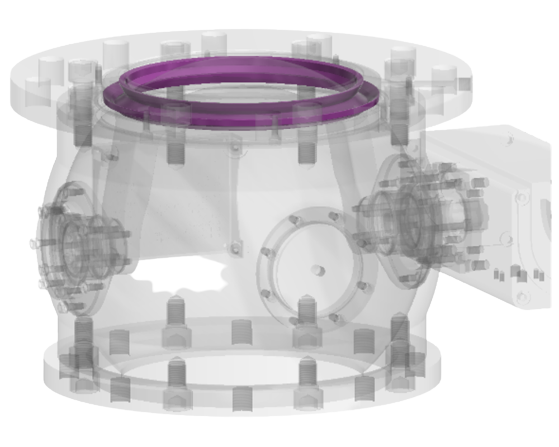

The sealing mechanism of a pressure segment valve is a vital component for its efficiency and reliability. Our valves incorporate an advanced inflatable seal, which offers an excellent seal performance by regulating pressure in an optimal way. This is particularly beneficial in applications where leakage can be harmful, such as in chemical processing or pharmaceutical industries.

Actuators and control systems

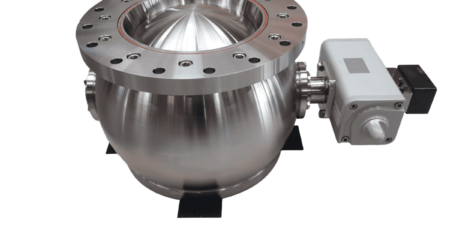

The operation of a pressure segment valve can be manual or automated, with the latter often employing electric or pneumatic actuators. These actuators are responsible for the precise movements of the valve shaft, ensuring accurate control over the flow and pressure of the medium.

Applications in various industries

Pressure segment valves find their applications in a wide range of industries due to their versatility and robustness. Let’s explore some of these applications:

- Chemical and pharmaceutical industries

In the chemical and pharmaceutical industries, pressure segment valves are used for controlling the flow of chemicals, organic solvents, and other mediums. Their corrosion resistance and ability to handle different temperature ranges from -10° to 135° degrees. make them ideal for these applications. For higher temperatures, like 200° degrees, Techno-G applies Perlast (FFKM) materials for it’s Inflatable seal. - Food processing

The food industry requires valves that can handle solids and slurries with easy. The non-clogging design of the pressure segment valves ensures a smooth flow of materials, maintaining the optimum flow rates necessary for efficient processing. - Metals and minerals

Handling solid particles in metals and mineral processing is challenging. Pressure segment valves excel in these environments due to their ability to handle abrasive and solid materials without clogging.

Download our free whitepaper

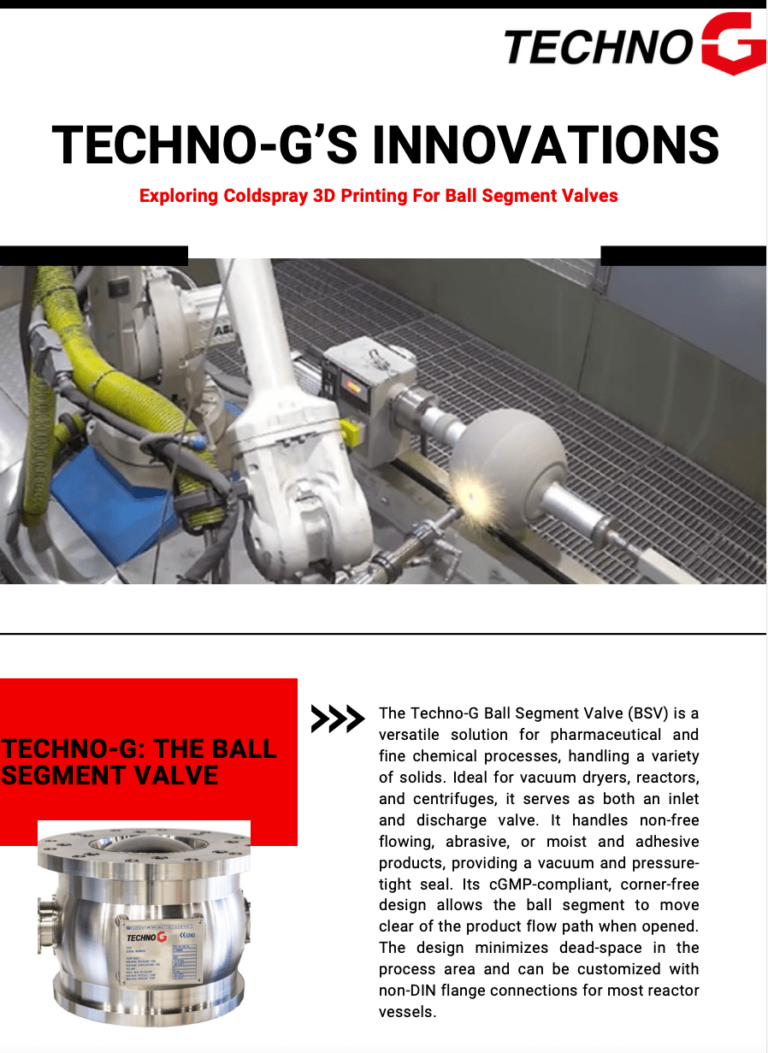

"Exploring Coldspray 3D Printing For Ball Segment Valves"

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

What about features and design considerations

Continuing our exploration of these types of valves, it’s important to explore the advanced features and critical design parameters that set these valves apart. Our ball segment valves are engineered with specific considerations in mind to ensure they meet the diverse needs of various industrial applications.

Advanced materials and corrosion resistance

The choice of materials for valve construction is critical, especially when dealing with corrosive fluids or harsh environments. Our valves are often made from stainless steel or other strong materials, based on the customer needs, providing not only durability but also application-specific corrosion and erosion resistance. This extends the service life of the valves, reducing the need for frequent replacements.

Precision in flow control

The precise control of fluid flow is crucial in many industrial processes. These valves offer backlash-free torque transmission, ensuring accurate control over the flow rate. This precision is essential in industries like pharmaceuticals and food processing, where maintaining consistent flow rates is essential for product quality.

Temperature and pressure handling capabilities

Pressure segment valves are designed to withstand various temperature configurations and pressure ranges. This versatility makes them suitable for a wide variety of applications where they manage fluids at high pressures and temperatures.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Tailoring to your specific industrial needs

One of the standout features of the ball segment valves is the ability to be tailored to your specific industrial needs. This customization can range from size variations, nozzles, flanges, and a heated flange head to special executions for unique applications.

Therefore we offer a range of customization options, if possible manufactured using a Titanium 3D coldspray printing technology, for Corrosive resistance and a long lasting reliable construction to special executions for unique application requirements. This flexibility ensures that each industry and customer gets a valve solution that perfectly fits its specific needs.

ATEX and Safety Considerations

For industries dealing with flammable or explosive materials, safety is of utmost importance. Our products comply with ATEX directives, ensuring they are safe for use in potentially explosive atmospheres, which is essential in industries like fine chemicals & solids handling.

Regulate your pressure with Techno-G

Pressure segment valves stand out for their precision, reliability, and adaptability to various industrial applications. From handling aggressive abrasive and corrosive solids in mining to managing delicate processes in pharmaceuticals, these valves prove to be an invaluable asset. The incorporation of advanced materials, innovative design, and rigorous quality control makes these valves a reliable choice for any industry requiring precise flow control and pressure management. For more information on how these valves can enhance your industrial processes, feel free to contact us or explore their wide range of valve options.