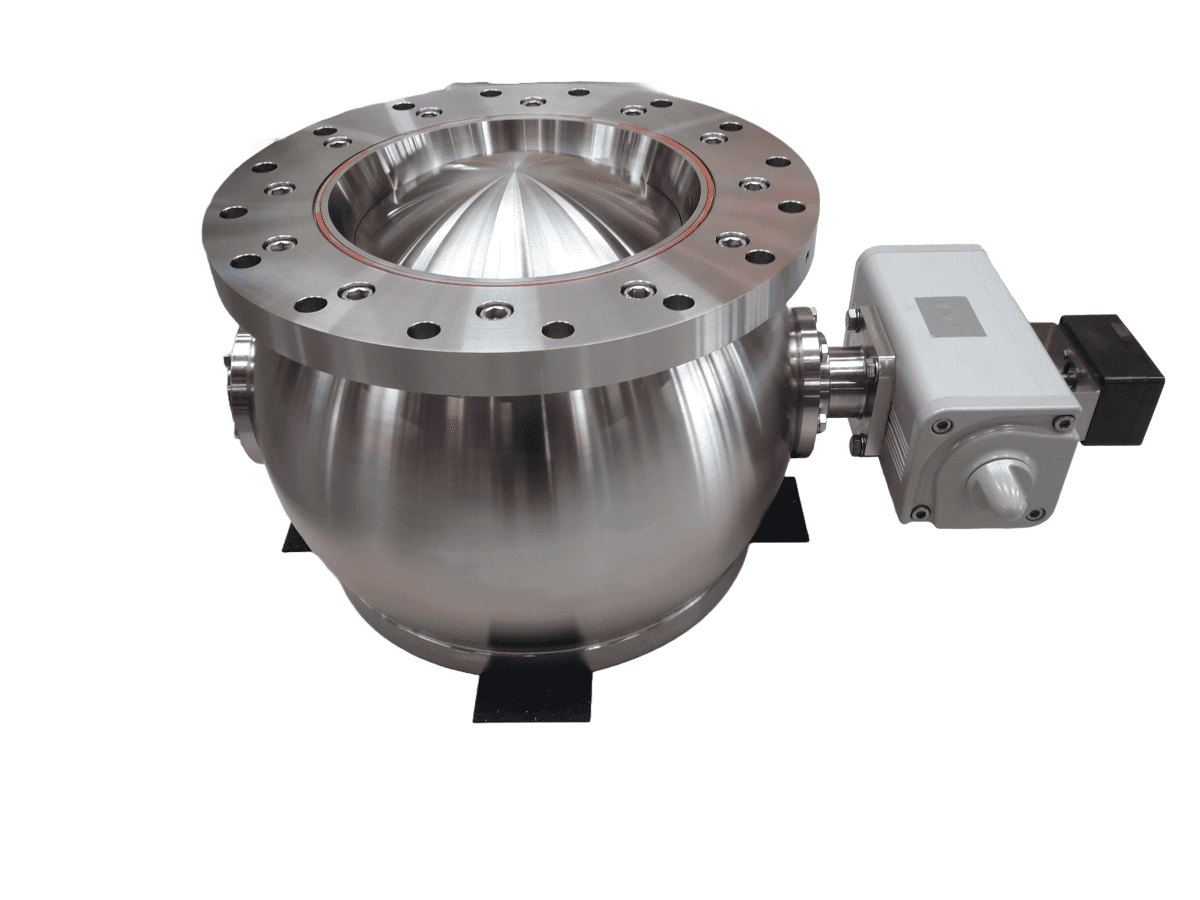

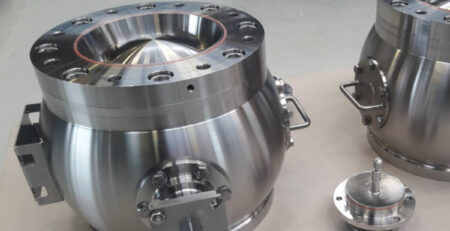

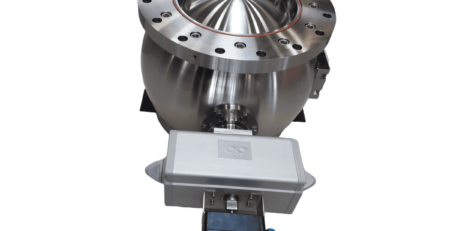

The role of Techno-G ‘s Ball Segment Valve in Optimizing Dry Granulation Processes

tim2024-02-05T11:27:28+00:00In the dynamic field of pharmaceutical manufacturing, optimizing processes is fundamental requirement to ensure the production of high-quality medications. In this sector, the role of the dry granulation manufacturing process lies in capitalizing on the advantages of compacting powder mixtures into granules. Within this process, the Ball Segment Valve (BSV) emerges as an indispensable solution, playing a crucial role in enhancing efficiency, reliability, and product quality.

Table of Contents

The Dry Granulation Manufacturing Process

Dry granulation involves mechanical compression through techniques such as slugging or roller compaction. This process is chosen when tablet excipients possess sufficient binding properties, and it offers the added advantage of preventing drug substance exposure to elevated temperatures during drying or moisture. While eliminating several manufacturing steps, dry granulation still requires meticulous processes, including weighing, mixing, slugging, dry screening, lubrication, and granule compression.

In this process, Techno-G’s ball segment valve serves as a versatile and crucial component in dry granulation processes in pharmaceutical manufacturing.

Handling Diverse Solids

The Ball Segment Valve is designed to handle a variety of solids encountered in pharmaceutical formulations. Its capability to manage non-free flowing, abrasive, or moist and adhesive products makes it an ideal choice for the diverse range of materials involved in dry granulation.

Vacuum and Pressure-Tight Seal

In processes utilizing vacuum dryers, maintaining specific conditions is imperative. The ball segment valve provides a vacuum and pressure-tight seal, ensuring the integrity of the manufacturing environment. This feature contributes to the precision and consistency of the dry granulation process.

cGMP-Compliance and Customization

Adhering to the current Good Manufacturing Practice (cGMP) standards, the Ball Segment Valve’s corner-free design allows the ball segment to move clear of the product flow path when opened, minimizing dead-space in the process area. Additionally, it can be customized with non-DIN flange connections at any kind of connecting execution, several material executions besides Stainless Steel 316L, such as Titanium and Hastelloy, catering to the specific requirements of various reactor vessels.

Preventing API Degradation

Dry granulation is preferred over wet granulation in scenarios where exposure to moisture could lead to API degradation. The Ball Segment Valve emerges as a key element in the dry granulation manufacturing process within the pharmaceutical industry. Its ability to handle diverse solids, provide a vacuum and pressure-tight seal, adhere to cGMP standards, prevent API degradation, and contribute to a shorter, cost-effective manufacturing process positions the Ball Segment Valve as a critical component in the pursuit of precision and excellence in pharmaceutical manufacturing. Reliability is also key, therefor each Techno-G Segment valve is executed with an inflatable seal to ensure full vacuum closing of the vessel.