What makes a valve suitable for a conical dryer application?

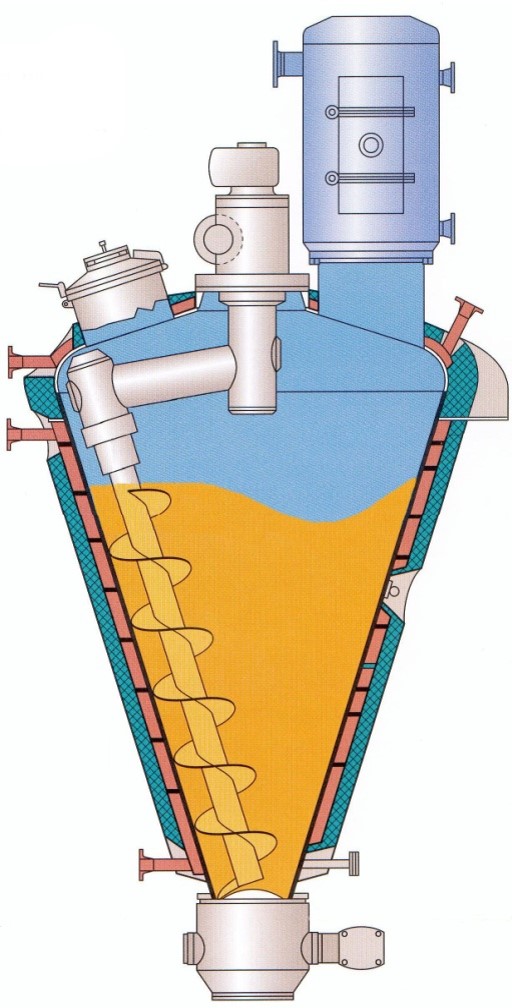

tim2024-08-08T14:13:03+00:00When looking closely at drying systems in many industries, you’ll find a lot of dryer valves. Yet, among these valves, typically suitable in the application for Conical Dryers, holds a unique stature. But what sets it apart? Let’s dive into the world of conical dryer valves, the innovations brought by Techno-G, and the cutting-edge advantages they introduce to industries, from pharmaceuticals to metals.

What makes a dryer valve so important?

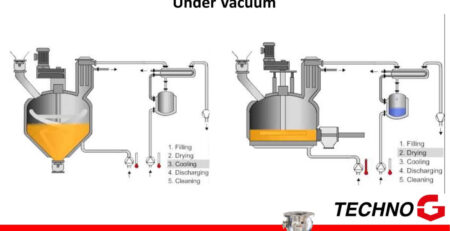

The essence of any industrial process is efficiency, especially when it comes to the crucial task of drying within sectors like pharmaceuticals and chemicals. Here, ensuring the perfect drying of active ingredients or proficient solid handling is vital. The significance of dryer valves in this scenario cannot be overstated as they play a pivotal role in managing the flow and maintaining the desired drying conditions within the system. The innovative solutions offered by specially designed dryer valves ensure a uniform drying process, effectively handling balls of product with utmost precision.

These valves are an integral part of a complete dryer system, tailored to cater to the unique demands of different industrial applications. They are particularly beneficial when dealing with heat sensitive materials, where maintaining precise drying temperatures is crucial to prevent any degradation in quality. The special design of these valves allows for vacuum treatment within the drying chamber, significantly lowering the drying temperatures compared to conventional systems. This not only ensures a higher quality of dry products but also contributes to making the drying process more energy-efficient and environment friendly.

"Having the right dryer valve can mean the difference between a batch of product being perfect or being rendered useless."

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Exploring the advantages of conical dryer valves

Enter the world of the conical dryer valve. Unlike your standard valves, this gem is designed with finesse, tailored to handle solids ranging from powdery textures to very fine particles and crystals. So, what gives the conical dryer valve this edge?

- Design superiority: As opposed to conventional ball segment valves, conical dryer valves, like those from Techno-G’s range of size, come with a design that seamlessly blends with various drying systems.

- Handling prowess: These valves can comfortably handle a diverse set of bulk materials. Be it the challenging fine chemicals and API or the more standard food products, the valve ensures optimal results.

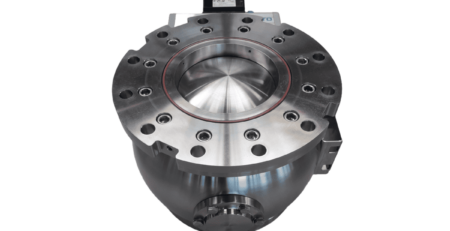

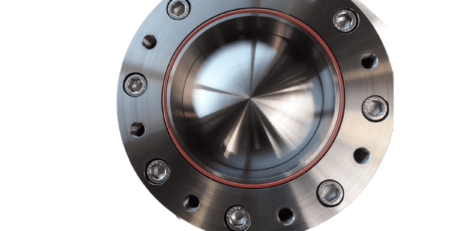

- Innovation at its best: Our patented inflatable seal ensures that that a vacuum is maintained without any leakage and thus a full shutting-off of the Dryer device is ensured. This inflatable seal, in combination with Techno-G’s ball segment valve, guarantees an optimal control over the drying process.

Why Techno-G stands out

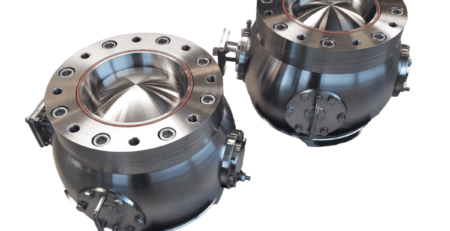

Techno-G isn’t just another name in the industry. We bring to the table a legacy of innovation and commitment. Started in 1985, our products, ranging from the 3D printed titanium ball segment valve to those with special executions, are a testament to their relentless drive for excellence. The focus on product quality control and certifications ensures that when you opt for us, you’re choosing reliability.

Techno-G ball segment valves are engineered to operate within a robust range of conditions, making them ideal for diverse industrial applications. With a standard design temperature spanning from -10 to 135 degrees Celsius and a pressure capacity ranging from -1 to 6 bar, these valves are built to handle challenging environments. The construction of each valve adheres to the EN13445 European Union standards for pressure vessel design, ensuring reliability and safety in operation. Additionally, the valves feature flanges that comply with the NEN-EN1092-1 standard, covering a wide range of specifications for circular steel flanges. Additional design parameters or execution upon request.

Customizable options for diverse needs

Every industry has its unique challenges. Recognizing this, Techno-G provides a range of size options for vacuum conical screw dryer valves, ensuring that regardless of the batch size or operational scale, there’s a solution that fits.

"In an ever-evolving industry, adaptability is key. Our valves offer unparalleled customization, from size to material, ensuring optimal performance."

Techno-G Expert

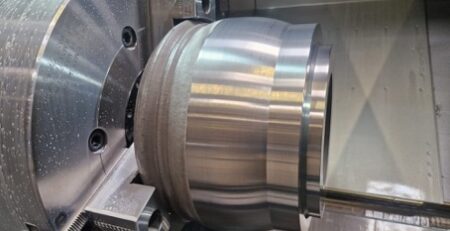

Innovative materials and design

One might wonder, what makes our valves so special? The answer lies in their design and the materials used. The 3D-printed titanium ball segment valves are not only lightweight but exceptionally durable. Their ability to resist chemicals further elevates their quality. Designed to function in temperatures from -10 to 135 degrees and withstand pressures from -1 to 6 bar, they cater to a broad spectrum of needs. Starting from sizes DN100 up to DN400, and also available in ANSI sizes from 4″ to 20″, our valves, with their precise material specifications, promise long-lasting efficiency and resilience against a variety of chemical interactions.

The essence of the inflatable seal

Techno-G’s inflatable seal is truly a game-changer. Not only does it ensure a tight and secure seal, minimizing loss, but its innovative design also ensures smooth handling of varied batch volumes. Specifically the 7-lipped seal face ensures a minimum of 3 lips closing off the valve, maintaining the vacuum at all times. Additionally, the seal is available in various material types, including EPDM W or B, Viton®W or B (FKM), and even executions in Perlast®(FFKM).

Safety and Quality

In an industry where safety is very important, we ensure that all our products meet stringent standards. With ATEX certification and a range of actuators, these valves are designed to operate safely in a variety of environments. Our commitment to quality is further evidenced by our extensive quality control and certification process.

To further ensure the highest standards of quality and safety, each Techno-G Ball Segment Valve undergoes rigorous hydrotesting. They are also available with a PED Certificate, in compliance with the “Pressure Equipment Directive 2014/68/EU,” certified by LRQA as the Notified Body. This certification underscores our commitment to delivering products that meet stringent European safety regulations. Moreover, the valves offer a variety of materials for inflatable seals, including EPDM White, EPDM Black, Viton White, Viton Black, and Perlast FFKM, catering to specific industry requirements and ensuring optimal performance across various applications. Read more about our quality control here.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Techno-G ball segment valves are found in a wide range of industries

Whether you’re in the pharmaceutical, chemical, food, or cosmetic industry, these valves cater to a broad spectrum of needs. From handling minerals in the minerals industry to ensuring efficient processing in the metals sector, The Ball Segment Valves prove essential. Curious about other industries we serve? Check out the extensive list of industries catered to.

Conclusion

In the dynamic world of process engineering, having the right tools and process equipment options is crucial. Techno-G’s valves offer advanced functionality and unique features, setting them apart from traditional options. Read more about these features here. Together with a wide range of customizable options and innovative materials, Techno-G’s Ball Segment Valves serve wide array of industries, they truly are a cut above the rest.

For those interested in exploring more or seeking a customized solution, don’t hesitate to reach out or request a quotation. After all, working with the best is always a good choice if you want to do things well and efficiently.