Techno-G Expands Material Options for Ball Segment Valves

Techno-G2024-10-18T09:49:31+00:00At Techno-G, our Ball Segment Valves are now available in a variety of advanced material configurations to meet the specific requirements of your applications. Whether you’re dealing with highly corrosive environments or high temperatures, we have the right material solution to ensure optimal performance and longevity.

Download our free whitepaper

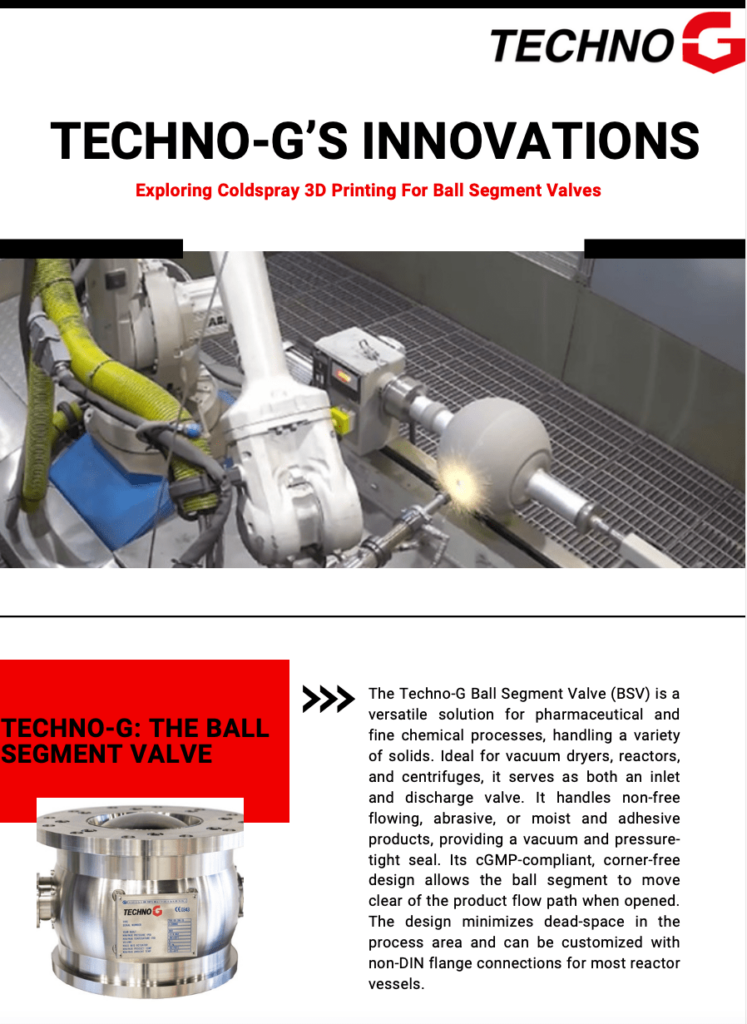

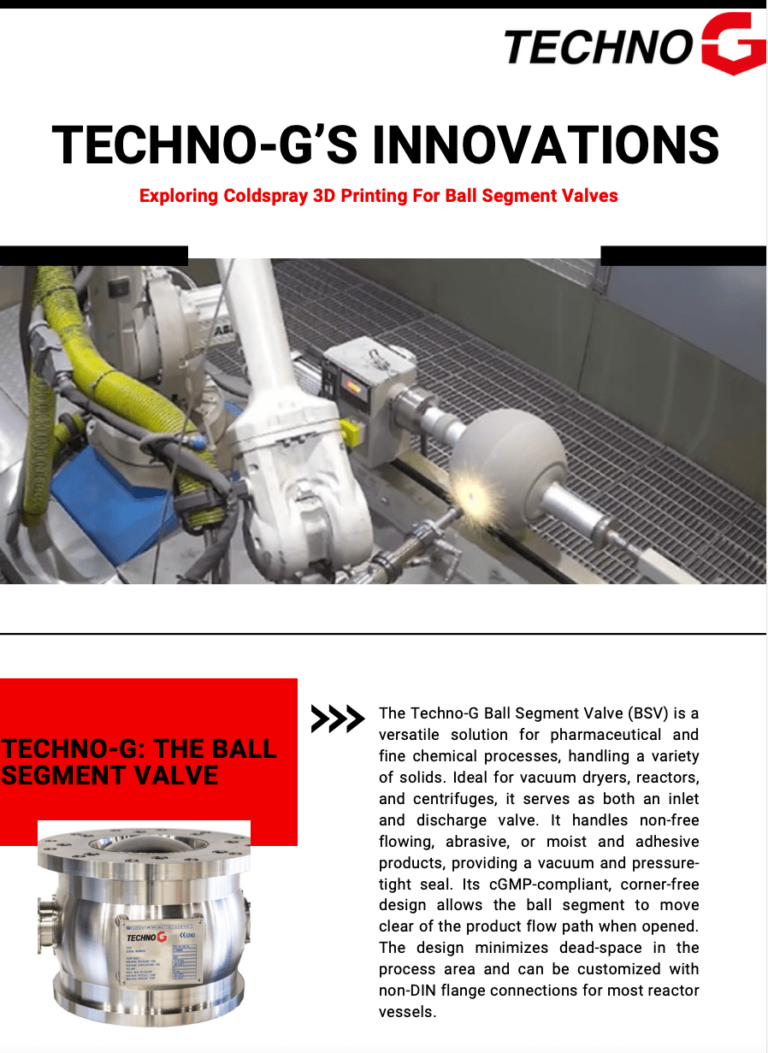

"Exploring Coldspray 3D Printing For Ball Segment Valves"

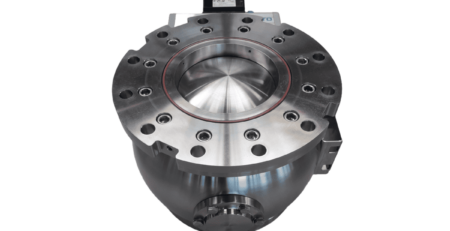

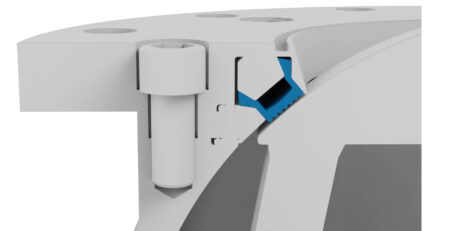

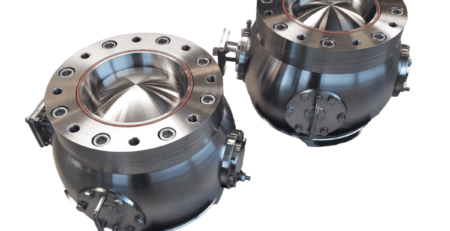

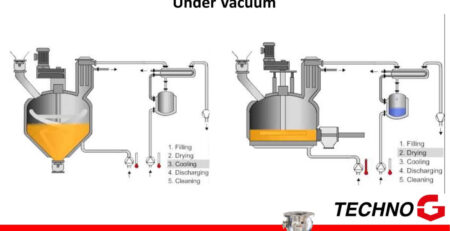

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Our Material Options: We understand that each application demands the right material execution, which is why we offer the following configurations:

- Full Stainless Steel (1.4404 or AISI 316)

- Partially Stainless Steel and Partially Hastelloy (1.4404 and 2.4602 or AISI C22)

- Full Hastelloy (2.4602 or AISI C22)

For applications requiring “product-contacted” or “wetted” parts, our valves with a “Partially Stainless Steel and Hastelloy” configuration use Hastelloy in these critical areas to provide enhanced corrosion resistance where it matters most.

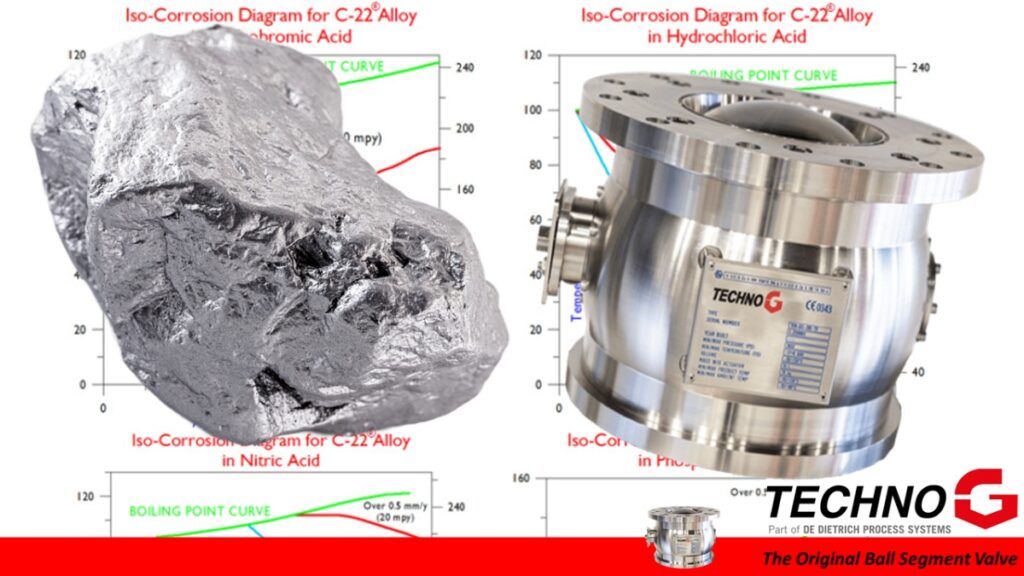

Why Choose Hastelloy C22 for Your Application?

Hastelloy C22 offers superior benefits in aggressive environments, particularly for high-temperature and vacuum dryer installations:

- Corrosion Resistance: Provides excellent protection against pitting, crevice corrosion, and stress corrosion cracking in harsh environments like acidic chemicals and oxidizing agents.

- High-Temperature Stability: Retains mechanical strength and corrosion resistance at elevated temperatures, outperforming stainless steel 316 in these conditions.

- Chemical Resistance: Offers broad protection against acids and halogens, making it ideal for complex chemical environments.

- Longer Lifespan & Lower Maintenance: With enhanced durability, Hastelloy C22 outlasts 316 in aggressive conditions, resulting in lower maintenance costs and extended operational lifespan.

- Improved Safety: Superior resistance to intergranular corrosion increases reliability in high-temperature or vacuum conditions, minimizing material failure risks.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Need Help Choosing the Right Material?

Whether you require Hastelloy C22 for demanding applications or stainless steel 316 for less aggressive conditions, we’re here to help you make the best choice. Our team is ready to provide expert guidance based on your unique needs.

For more information on our Ball Segment Valves and material options, contact us or visit www.techno-g.com.

Contact us:

Email: sales@techno-g.com or info@techno-g.com

Phone: +31 (0)58 2139 715