Hard Inchromising for Ball Segment Valve Heads

Techno-G2024-10-31T08:52:19+00:00In the (petro)chemical, pharmaceutical, and food industries, high-quality stainless steel alloys and nickel-based materials are frequently utilised. Although the choice of these materials may seem straightforward, they are unfortunately susceptible to corrosion and wear under certain conditions.

When these materials are used in dynamic components, conventional techniques and materials often fall short in aggressive and abrasive environments where both wear resistance and corrosion resistance are crucial. Corrosion-induced wear or wear-induced corrosion leads to rapid degradation of machine parts, causing unscheduled production downtimes and resulting in unnecessary costs and frustration.

If the chosen stainless steel material has sufficient corrosion resistance but wear or cold welding poses a challenge, Hard Inchromising may be the ideal solution. This treatment produces an exceptionally hard and wear-resistant surface while preserving corrosion resistance, with minimal effect on product dimensions. This treatment method is being widely adopted across various industries, including recent applications in the soldering sector.

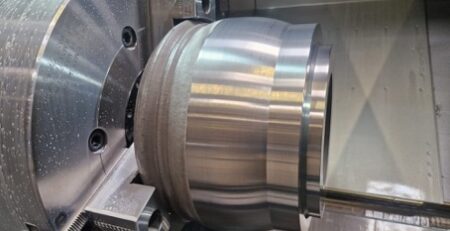

This treatment method enhances product wear resistance by applying a ceramic chrome carbide (CrxCy) layer. Wherever abrasive or adhesive wear occurs, this unique layer greatly extends the service life of components. The treated surface is extremely hard-wearing, with a dense structure and excellent operational properties. Hard inchromising ensures a longer service life, less downtime, fewer costly production halts, and lower overall expenses.

Download our free whitepaper

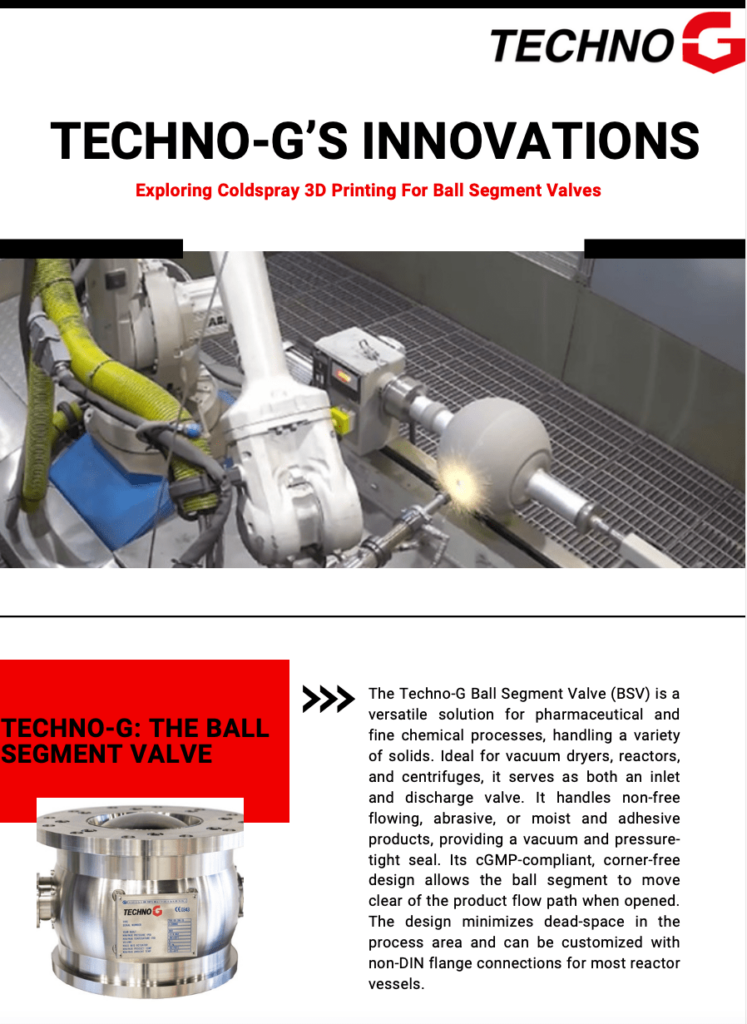

"Exploring Coldspray 3D Printing For Ball Segment Valves"

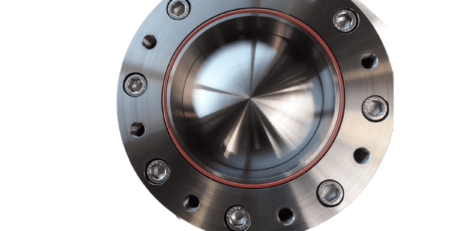

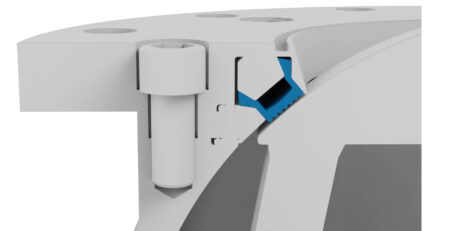

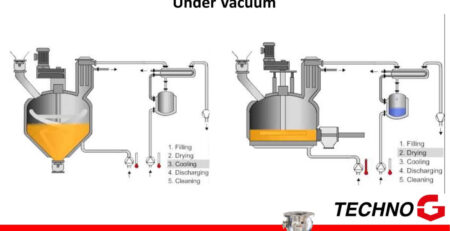

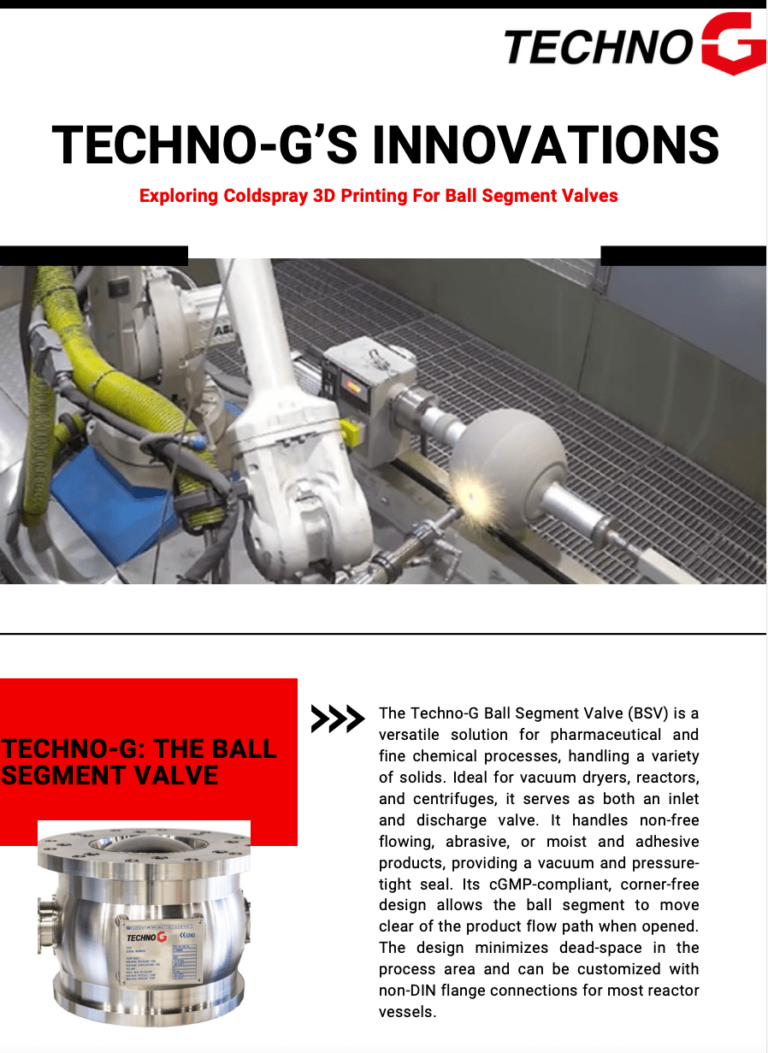

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Characteristics of Hard Inchromising

- Layer Depth: 5–25 µm

- Temperature Resistance: up to 850°C

- Surface Hardness: approximately 2000 Micro-Vickers

- Reduces Overall Costs

- Sealed, Homogeneous Layers

- Very Low Coefficient of Friction

- High Oxidation Resistance

- Suitable for All Ferrous Metals, Including High Nickel and Molybdenum Alloys

- Corrosion and Erosion Resistant

- Good Anti-Stick Properties for Easier Cleaning

- Additional Heat Treatments Possible During and After Hard Inchromising

- Layer Depth: 5–20 µm

- Temperature Resistance: up to 900°C

- Surface Hardness: approximately 2000 Micro-Vickers

- Reduces Overall Costs

- Elastic and Highly Malleable

- Low Coefficient of Friction

- Improves Wear Resistance

- Retains Corrosion Resistance