The conical dryer valve: Key to efficiency

tim2024-08-08T14:19:34+00:00In the dynamic world of industrial drying, the conical dryer valve stands as a pinnacle of innovation and efficiency. At Techno-G, we specialize in ball segment valves, renowned for their precision in handling fine solid materials. However, when it comes to the specific area of solids handling processes, these types of valves are a very reliable and efficient option. In this article we delve into the unique aspects of the conical dryer valve, contrasting it with other types of dryer valves and highlighting its benefits.

Table of Contents

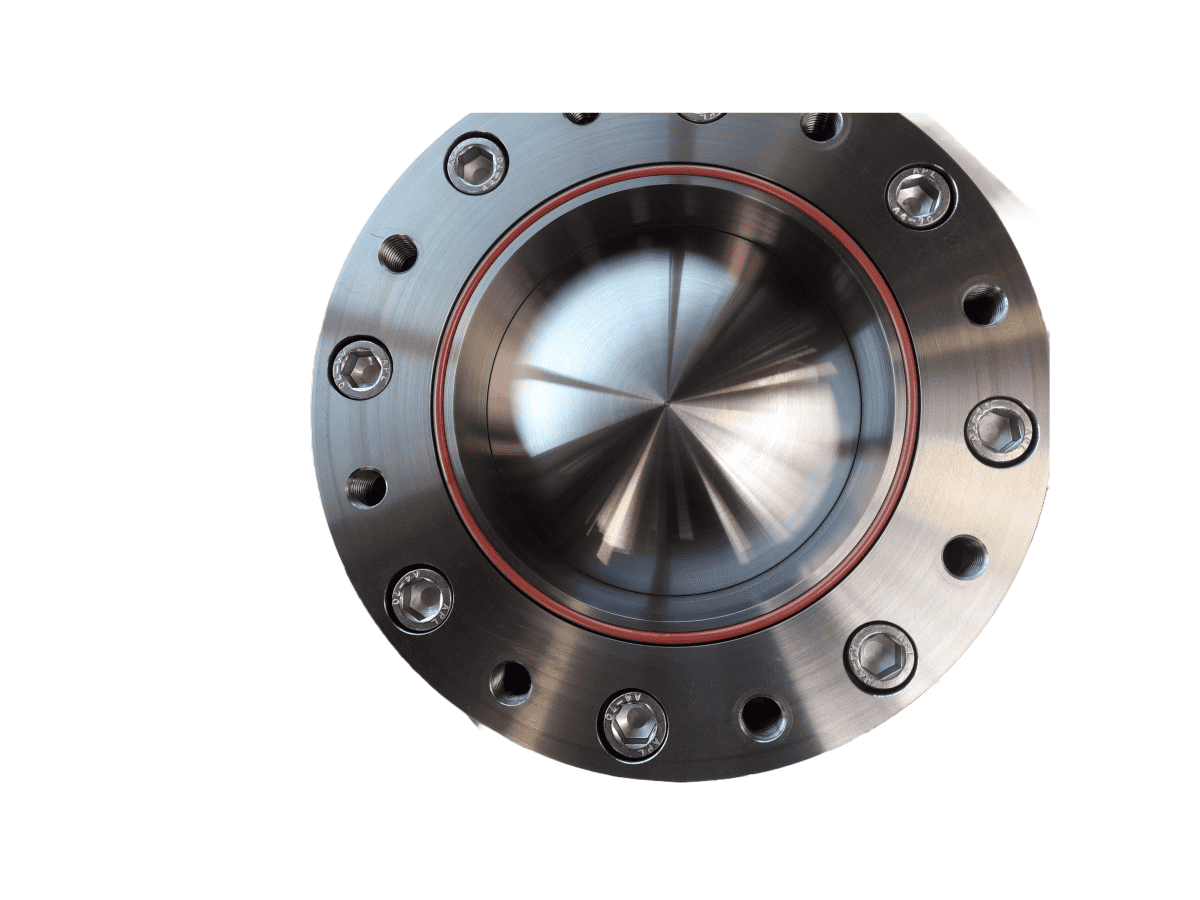

What sets the conical dryer valve apart?

At the heart of a conical vacuum dryer, the conical dryer valve plays an essential role. Unlike other valves, this valve boasts a design that is inherently suited for the handling of batch sizes of products, ensuring efficient batch drying and optimal process parameters.

Unique design and functionality

This valve, often found in systems like the conical screw vacuum dryer, features a design tailored for efficient processing. It ensures:

- Improved heat transfer: The shape and structure of the conical dryer facilitate better heat transfer performance, crucial for heat-sensitive products.

- Optimal drying rates: The valve’s design aids in achieving efficient drying rates, reducing drying times significantly, which is important in industries with a long processing time.

- Enhanced product quality: Due to its gentle solid handling capabilities, it is ideal for delicate or hazardous substances, ensuring product quality and safety.

Technological advancements

Incorporating advanced technology, valves for conical dryers offers:

- Energy efficiency: Given the increasing focus on environmental themes and sustainability achievements, this valve’s design contributes to lower energy consumption.

- Automated cleaning solutions: Its compatibility with automated cleaning solutions ensures high hygienic standards, especially important in the pharmaceutical and food industries.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Applications in various industries

The conical dryer valve finds its place in numerous industries due to its advanced functionality and efficient process design. It’s particularly useful in:

- Pharmaceuticals: For drying sensitive pharmaceutical ingredients, ensuring product recovery, and maintaining industry standards.

- Chemicals: In the chemical industry, it’s used for granulation of solids and handling of toxic products.

- Food and cosmetics: These industries benefit from its gentle product handling and hygienic design.

Download our free whitepaper

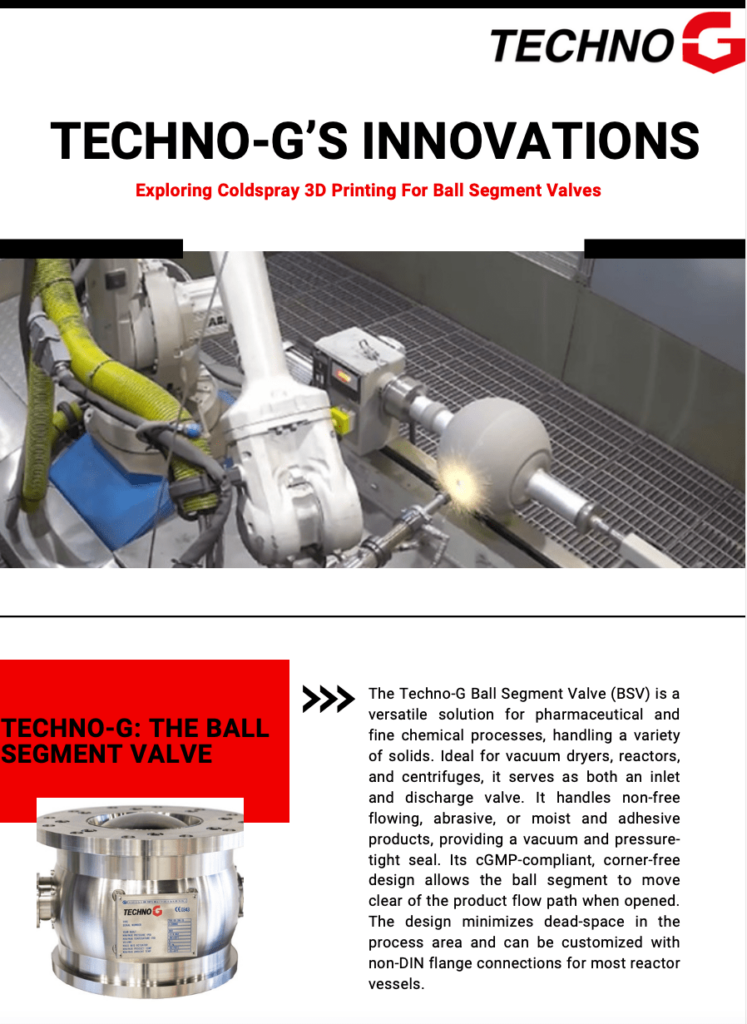

"Exploring Coldspray 3D Printing For Ball Segment Valves"

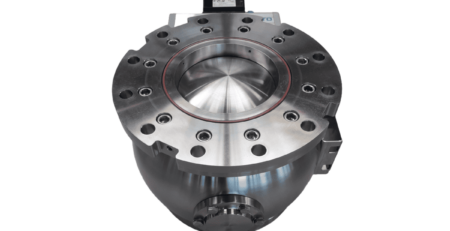

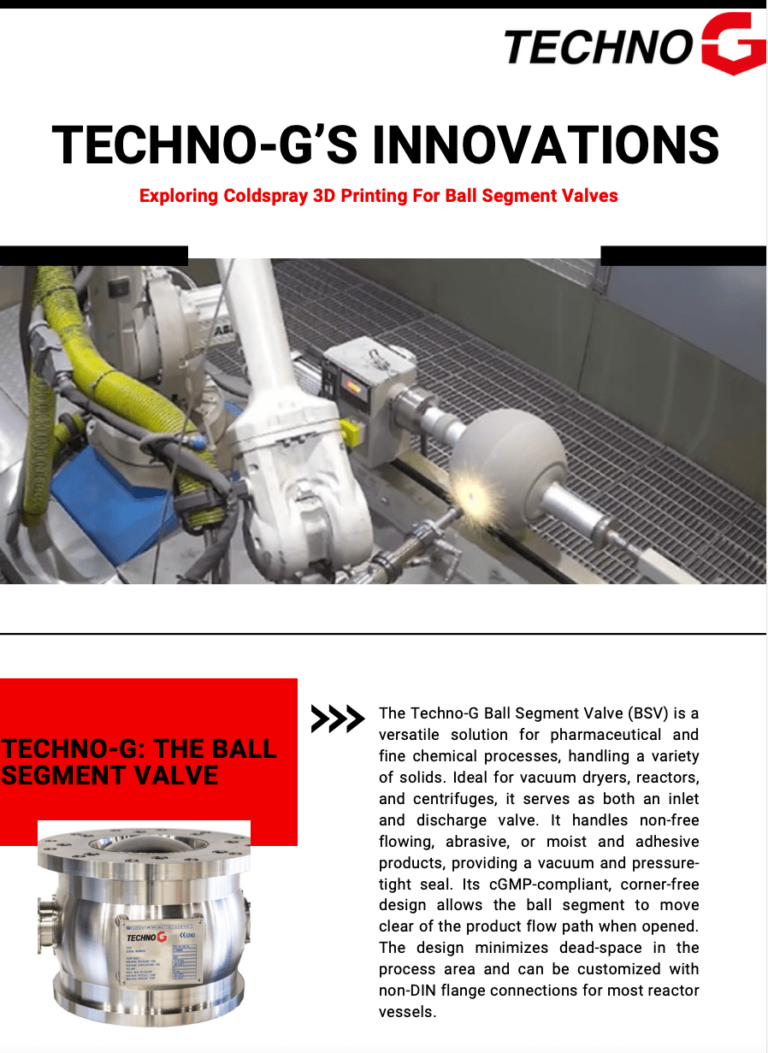

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Advanced features and bespoke solutions

The realm of industrial drying is constantly evolving, and at Techno-G, we pride ourselves on staying ahead of the curve. Our ball segment valves are not just standard components; they are a crucial part of complete solids processing systems, designed to meet the bespoke needs of various industries.

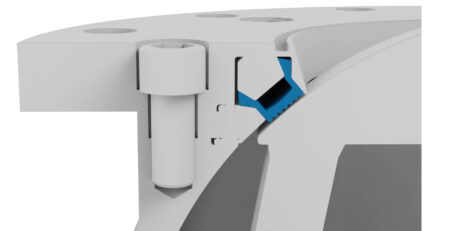

Customization and flexibility

Understanding that each industry has unique requirements, we offer:

- Bespoke capacities: From small experimental purposes to large industrial processes, our valves cater to a broad capacity range.

- Tailor-made design: We collaborate with clients to develop bespoke system solutions that align perfectly with their specific processing needs. Think of essential brackets, Neumo flanges, PTFE Lining and more.

Technological Integration

Our valves, optimized for conical dryers, are not just mechanical components; they are part of a sophisticated system that includes:

- Advanced control systems: With options like the control box, we provide users with precise control over their drying processes.

- Energy management: By focusing on energy efficiency, our valves contribute to reducing overall energy consumption, aligning with modern environmental and sustainability standards.

Advantages in maintenance and durability

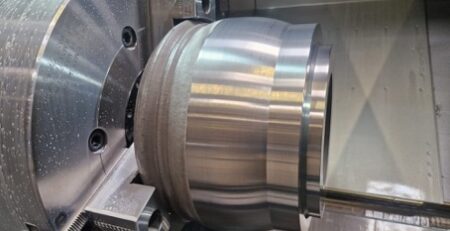

Maintenance and longevity are essential factors in industrial equipment. Our ball segment valve, with its robust design and quality materials like stainless steel, offers significant benefits:

- Ease of maintenance: Features like the exploded view aid in easy maintenance and part replacement.

- Durability: The use of high-quality materials ensures that our valves withstand the corrosion of industrial use, reducing the frequency of replacements.

Application insights: From pharmaceuticals to food processing

The versatility of the valve for conical dryers allows it to be an integral part of various industry-specific applications.

1. Pharmaceuticals

In the pharmaceutical industry, precision and contamination-free processing are paramount. Our valves offer:

- Sterile processing: Ensuring that the final pharmaceutical products are free from any contaminants.

- Controlled environment: Essential for the treatment of heat-sensitive and delicate pharmaceutical ingredients.

2. Food industry

The food industry benefits immensely from the hygienic and efficient nature of our valves. They provide:

- Consistent quality: Essential for maintaining taste, texture, and nutritional value in food products.

- Regulatory compliance: Meeting the stringent standards set by food safety authorities.

3. Chemicals and more

In industries like chemicals and fine chemicals-API, our valves facilitate:

- Safe handling: Safe handling of potentially hazardous substances, ensuring worker and environmental safety.

- Efficient processing: Optimizing the drying phase for various chemical compounds.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

A component that transforms your processes

The conical dryer valve is more than just a part of the machinery; it’s a transformative component that enhances the efficiency, safety, and quality of industrial drying processes. As no other, we understand the intricacies of these processes and are committed to providing solutions that not only meet but exceed your expectations. Explore our range of innovative solutions and let us help you optimize your industrial processes with our advanced, reliable, and bespoke valve technologies.