How a pharmaceutical solids valve ensure secure handling

tim2024-02-05T12:04:47+00:00In the demanding field of pharmaceutical manufacturing, the handling of solid materials requires not just precision but also a commitment to safety and efficiency. At Techno-G, we understand these needs. Our pressurised ball segment valves, renowned for their precision and reliability, are tailor-made for the pharmaceutical sector, where the safe and secure handling of solids is not just a requirement but a necessity.

Table of Contents

Understanding pharmaceutical solids handling

Pharmaceutical solids handling covers a wide range of materials, from granulated forms to powders and active ingredients. These materials, often sensitive and reactive, demand a handling solution that is not just effective but also hygienic and compliant with stringent industry standards.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

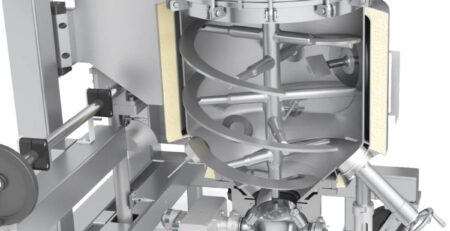

The role of ball segment valves in pharmaceutical industries

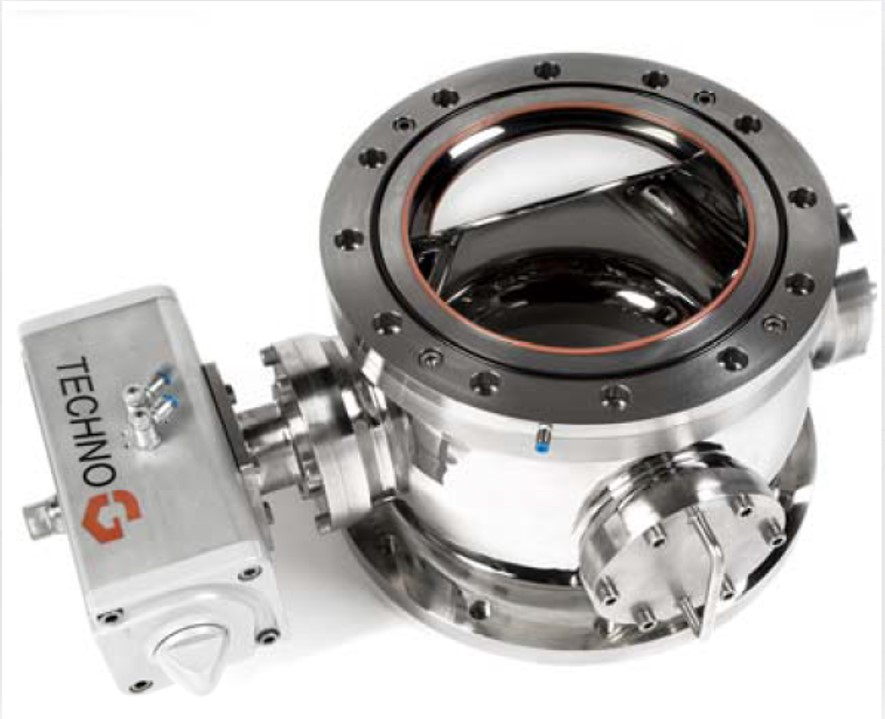

Our ball segment valves, designed specifically for pharmaceutical applications, offer unparalleled control and efficiency in the handling of solids. The inflatable seal technology ensures a tight closure, preventing contamination and ensuring the integrity of the material being processed.

The modular design of our valves allows for easy maintenance and adaptability to various installation criteria. Made from high-grade materials like stainless steel and, in special executions, 3D-printed titanium, or Hastelloy, these valves are not only durable but also suitable for corrosive applications and varying temperatures, a common scenario in pharmaceutical processing.

Flexibility and efficiency in operation

With options for manual actuation and electric operation, our valves offer flexibility in control, essential for maintaining the precise flow rates and particle sizes required in the pharmaceutical industry. The actuation valve system is designed for efficient maintenance, ensuring minimal downtime and consistent performance.

Safety and compliance

Safety in pharmaceutical manufacturing is also paramount. Our ball segment valves adhere to stringent quality control and certification standards. They are engineered to handle not only the flow of material efficiently but also to operate safely in potentially explosive atmospheres, as outlined in our ATEX-certification.

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

The Techno-G difference in solids handling

At Techno-G, our commitment goes beyond just supplying valves. We strive to understand the unique needs of the pharmaceutical sector, offering solutions that are not just products but part of a comprehensive system for handling pharmaceutical solids safely and effectively. From a valve size starting at DN100 all the way up to DN500, we contribute to the success of your operations.

Advanced features for ultimate performance

The advanced features of our ball segment valves are designed to meet the diverse needs of the pharmaceutical industry. These features include:

- Versatile material handling: Our valves handle a wide range of materials, from solids to fine chemical powders, ensuring versatility across various pharmaceutical applications.

- Customizable options: With a range of size options and material specifications, our valves can be tailored to suit specific application requirements, ensuring optimal performance.

- Innovative sealing technology: The inflatable seal provides an airtight closure, crucial for maintaining the purity and quality of sensitive pharmaceutical solids.

Ensuring compliance and safety

In the pharmaceutical industry, compliance with regulatory standards is not just a requirement but a necessity for ensuring the safety and efficacy of products. Our valves are designed with this in mind, ensuring compliance with industry standards and regulations. The quality control and certifications of our products speak to our commitment to safety and reliability.

Our advantage in handling solids

Choosing Techno-G’s ball segment valves means opting for a solution that brings several advantages to the table, including:

- Enhanced product integrity: By preventing contamination and ensuring precise flow control, our valves play an essential role in maintaining the integrity of pharmaceutical products.

- Operational efficiency: The ease of operation and maintenance of our valves, coupled with their compact design, contributes to overall operational efficiency, reducing downtime and increasing productivity.

- Customization and flexibility: The ability to customize our valves according to specific needs, whether it’s in terms of material, size, or operation, ensures that our solutions are flexible and adaptable to any solids handling scenario.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Secure your handling processes

The safe and secure handling of pharmaceutical solids is a challenge that requires specialized solutions. At Techno-G, we offer not just products but comprehensive solutions designed to meet the unique demands of the pharmaceutical industry. Our commitment to quality, safety, and efficiency makes our ball segment valves an ideal choice for pharmaceutical solids handling.

Discover more about our innovative solutions by visiting our product page or learn about their applications in different industries.