Techno-G Inflatable seal Characteristics

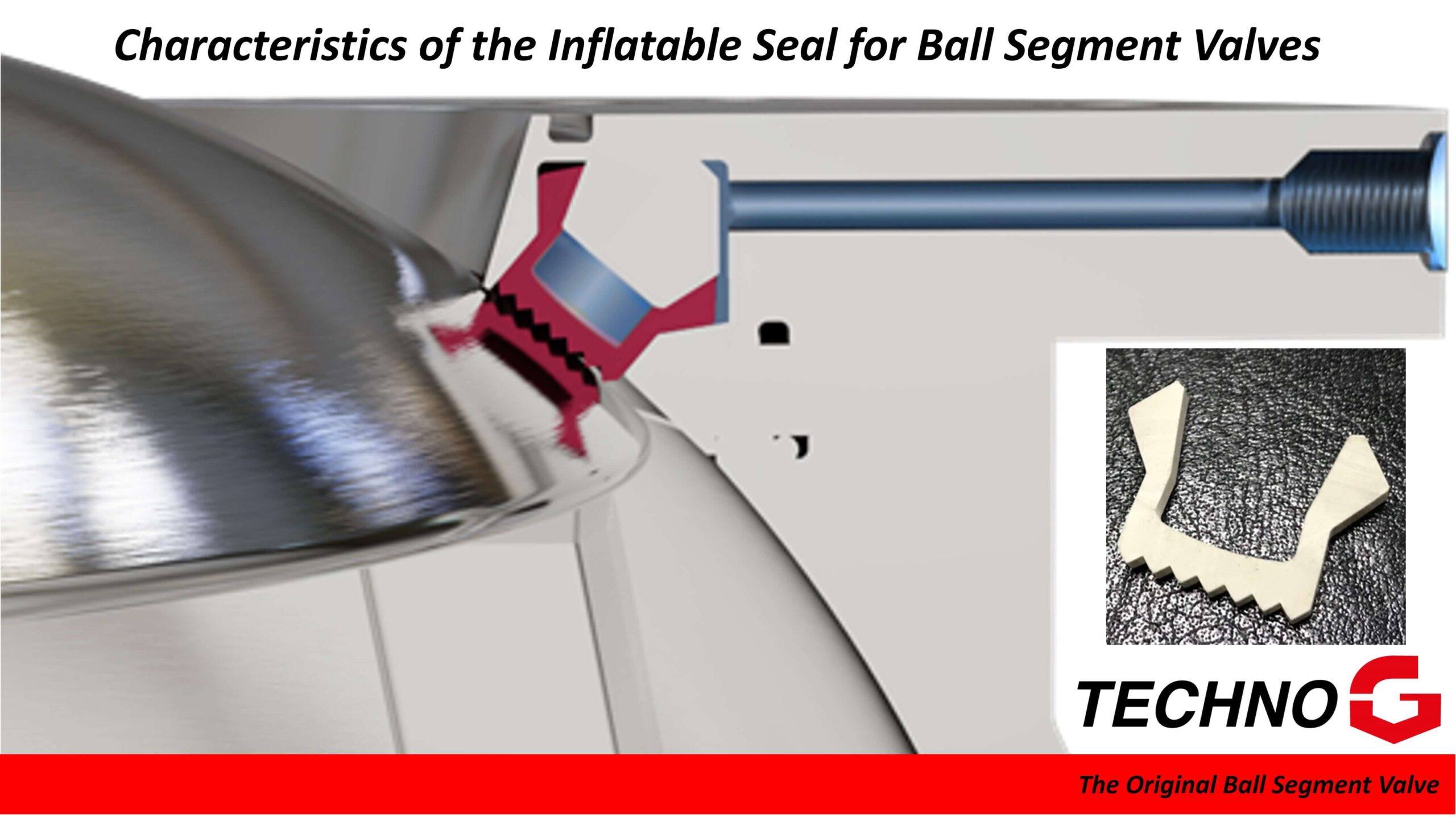

tim2024-03-20T17:56:18+00:00The inflatable seal is a very important element in the Ball-Segment-Valve. In its inflated state, it fills the narrow gap between the segment and the scraper ring, which is fixed to the housing. This scraper ring functions to clear away any solidified deposits on the segment prior to its passage by the seal. Furthermore, it acts as a barrier, preventing larger particles from approaching the area of the inflatable seal.

Table of Contents

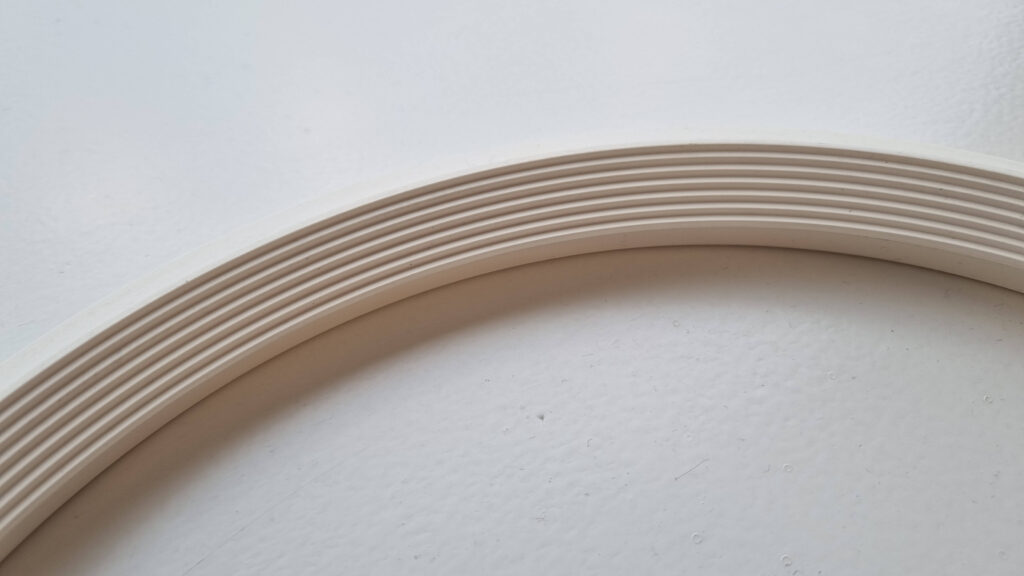

The materials from which the inflatable seal is manufactured can be various and are applied according the purpose of the Ball Segment Valve with the solids product it is designed for.

These Inflatable seal materials are:

- PTFE (Viton) White

- PTFE (Viton) Black

- EPDM White

- EPDM Black

- FFK – Perlast (White)

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Differences between these products are:

PTFE (Polytetrafluoroethylene) and EPDM (Ethylene Propylene Diene Monomer) are both types of synthetic rubber, but they have distinct properties and are used in different applications due to their unique characteristics:

Chemical Resistance:

- PTFE: It is highly resistant to a wide range of chemicals, including acids, bases, and solvents. This makes it suitable for use in harsh chemical environments.

- EPDM: While it has good resistance to mild acids, alkalis, and some solvents, it is not as broadly chemically resistant as PTFE. EPDM is more commonly used in applications involving water, steam, or mild chemicals.

Temperature Resistance:

- PTFE: It can withstand extremely high temperatures, typically up to 260°C (500°F), and is also effective at very low temperatures.

- EPDM: It has a good temperature range but is generally limited to a maximum of around 150°C (300°F). It also performs well in cold temperatures.

Physical Properties:

- PTFE: It is known for its low friction and non-stick properties, making it ideal for applications where sliding action is required, such as coatings for cookware and seals in machinery.

- EPDM: It is extremely durable and flexible, with excellent resistance to weather, ozone, UV radiation, and aging, making it ideal for outdoor applications like roofing, car seals, and weatherstripping.

Electrical Properties:

- PTFE: It is an excellent insulator, with high dielectric strength, low dielectric constant, and low dissipation factor, useful in electrical and electronic applications.

- EPDM: While it has good insulating properties, it is not as effective as PTFE in high-frequency or high-voltage applications.

Permeability:

- PTFE: It has very low permeability to gases, which is beneficial in applications where gas tightness is important.

- EPDM: It is more permeable than PTFE, which may be a limiting factor in certain sealing applications.

In summary, PTFE is preferred for applications requiring high chemical resistance, extreme temperatures, or low friction, while EPDM is favored for outdoor applications requiring good weather resistance, flexibility, and cost-effectiveness.

When High temperatures or high chemical resistance is required, the option to choose for FFKM Perlast can also be made.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

What are the characteristics of FFKM Perlast?

FFKM, often known by the trade name Perlast, is a type of perfluoroelastomer, which is among the most chemically resistant elastomers available. Here are its key characteristics:

- Exceptional Chemical Resistance: FFKM offers near-universal chemical resistance. It is resistant to almost all chemicals, including acids, bases, solvents, and steam. This makes it suitable for use in highly aggressive chemical environments where other materials would degrade.

- High-Temperature Resistance: FFKM elastomers can withstand extreme temperatures, typically up to 325°C (617°F) and in some cases, even higher. They also retain their properties at very low temperatures, making them suitable for a wide range of temperature conditions.

- Outstanding Mechanical Properties: FFKM provides excellent sealing performance under high pressures and in harsh conditions. It has good compression set resistance, which means it maintains its shape and sealing force even after repeated compressions and exposures to harsh conditions.

- Low Permeability: FFKM has very low permeability to gases. This makes it an ideal choice for applications requiring tight seals, such as in the semiconductor, aerospace, and oil and gas industries.

- Excellent Aging and Weather Resistance: FFKM is highly resistant to ozone, UV light, and weathering, which makes it suitable for outdoor use and in harsh environmental conditions.

- Thermal Stability: FFKM maintains its mechanical properties over a wide range of temperatures, making it stable and reliable in applications with thermal cycling.

- Purity: FFKM materials are often manufactured to have low outgassing and low extractables, making them suitable for cleanroom environments, such as in semiconductor manufacturing.

- Cost: FFKM materials are generally more expensive than other elastomers due to their superior performance characteristics. Their use is typically justified in applications where other materials fail to meet the required performance standards.

Due to these characteristics, FFKM elastomers are commonly used in applications where extreme conditions are present, such as in the chemical processing industry, oil and gas exploration and production, semiconductor wafer fabrication, pharmaceutical and food processing, and aerospace applications.

If you have any kind of solid material which needs to be handled with a Ball Segment Valve and inflatable seal, Please look further at: https://www.techno-g.com/ball-segment-valve/inflatable-seal/ or contact Info@techno-G.com and inform us about your request.

If you want to know more about techno-G: please visit www.techno-g.com