Techno-G’s Quality and Certification Standards for Ball Segment Valves

tim2024-07-15T14:46:26+00:00At Techno-G, we are proud to set new benchmarks in the valve manufacturing industry with our high-quality ball segment valves. Our commitment to stringent quality control measures and key certifications ensures that every valve we produce meets the highest standards of performance and reliability.

Table of Contents

Our Rigorous Quality Assurance

We ensure that our valves are built toresist the toughest conditions. Compliance with industry regulations and standards is a mandatory aspect of our manufacturing process, covering:

- Pressure Equipment Directive (PED)

- Conformité Européene (CE)

- European Guidelines (EG)

- Atmospheres Explosibles (ATEX)

- Material Certificates

- Manufacturing Data Books

- Local regulations

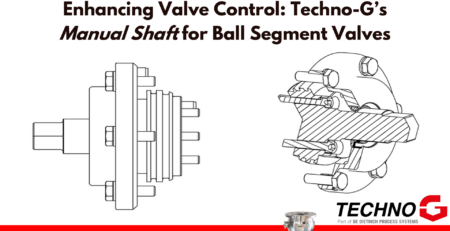

High Manufacturing Standards

Our valve housings are crafted according to EN13445 European standards, and feature flanges built to the NEN-EN1092-1 standard, ensuring great construction quality.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Thorough Testing

Every valve undergoes rigorous hydrotesting. We provide a PED Certificate in compliance with the Pressure Equipment Directive 2014/68/EU, verified by LRQA.

Pressure Tests

Our pressure tests are designed to ensure that each valve can withstand high-stress conditions. By simulating real-world pressures, we verify the integrity and durability of our valves.

Download our free whitepaper

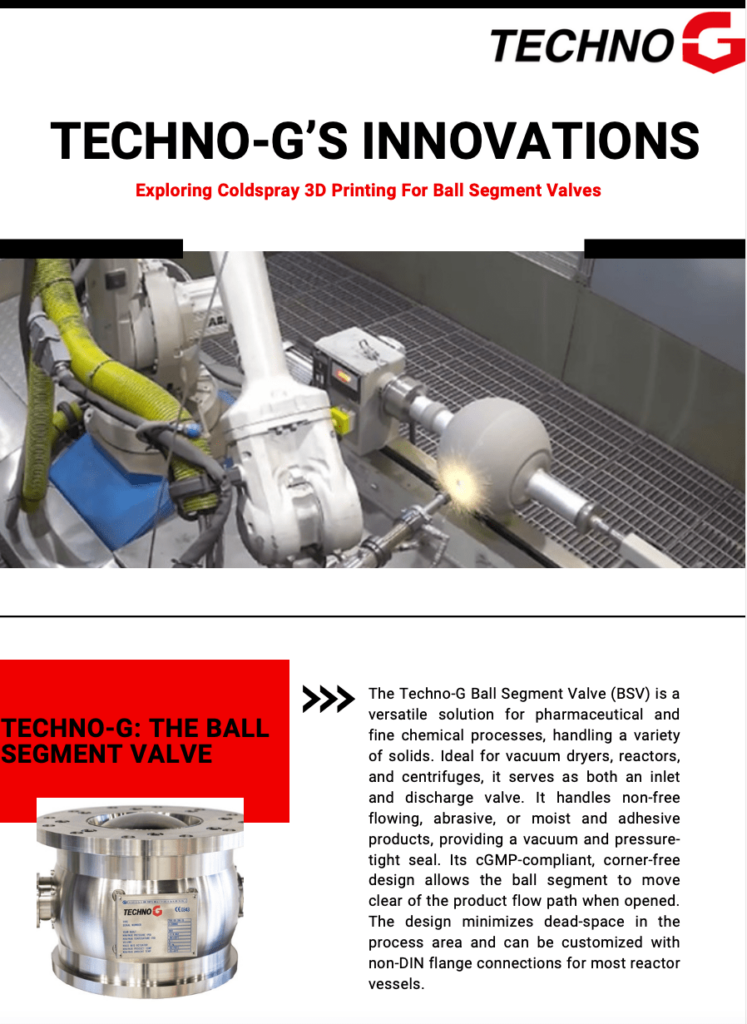

"Exploring Coldspray 3D Printing For Ball Segment Valves"

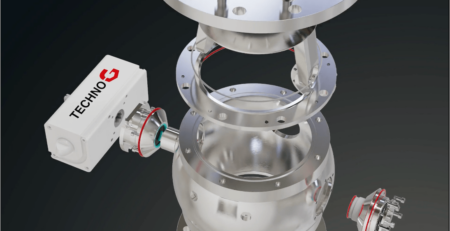

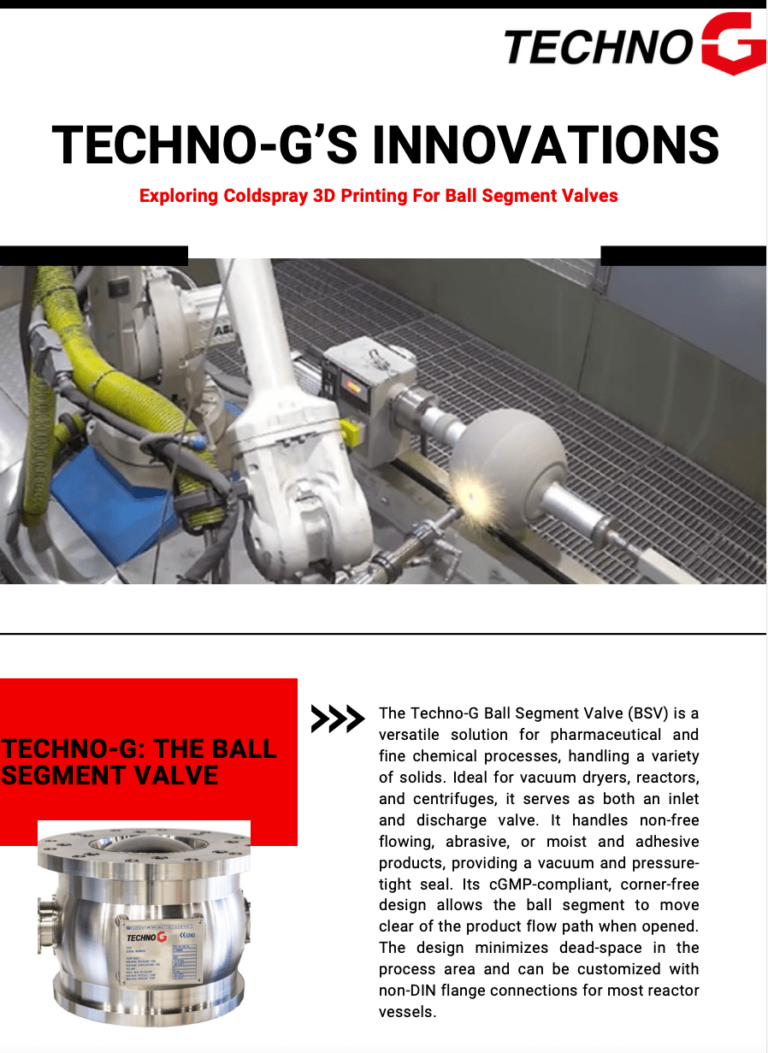

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Documentation

Each valve comes with a detailed Manufacturing Data Book that includes:

- Various certificates

- Instructional and Operational Manuals

- CE and EG Declarations

- ATEX regulations (when applicable)

- A signed and stamped Hydrotest certificate

Our manuals also include an Inspection Test Plan (ITP) approved by LRQA, along with photos of the hydrotest procedure.

Packaging

Once all quality checks are passed, each valve is carefully packaged and labeled, ensuring all necessary documentation and packing lists are included for safe and organized delivery.

ISO 9001 Certification

Our commitment to quality is further demonstrated by our ISO 9001 certification, which is available for download on our website. Additionally, our website features two available quality control videos that showcase our process.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Conclusion

At Techno-G, our dedication to quality control and certification ensures that our ball segment valves deliver unmatched reliability and performance. We are proud to be a trusted leader in the valve manufacturing industry.

If you are interested in learning more about our Quality and Certification Standards check out our website.

Contact us:

Email: sales@techno-G.com or info@techno-G.com

Phone: +31 (0)58 2139 715