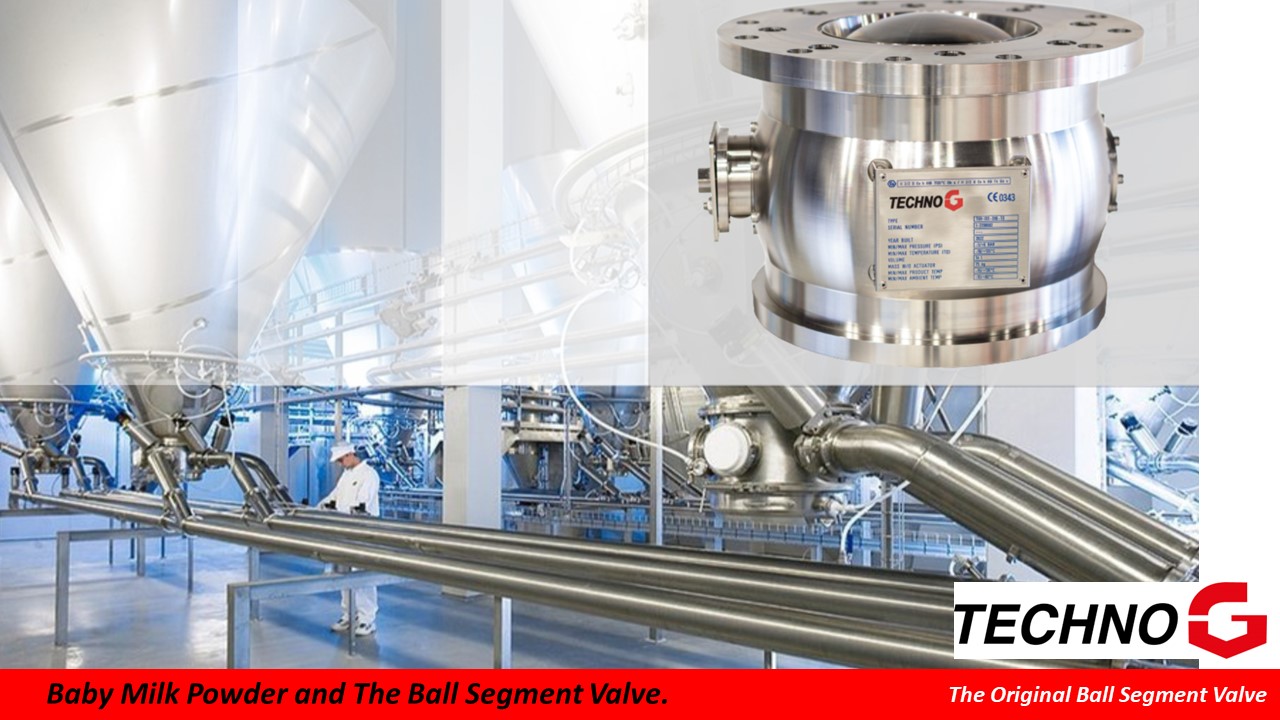

Ball Segment valve and baby milk powder

tim2023-11-17T15:51:38+00:00Safety and Efficiency in Baby Milk Powder Production Achieved Through the utilization of Techno-G Ball Segment Valve

Baby milk powder production is a delicate process that demands precise control, hygiene, and quality assurance to ensure the safety and nutritional value of the final product. A critical player in this manufacturing journey is the Ball Segment Valve provided by Techno-G.

Baby milk powder is a staple in households around the world, serving as a primary source of nutrition for infants. To meet the stringent quality and safety standards of this industry, the production process must be punctiliously controlled. A critical element of this procedure involves the Vacuum in the vessel and the discharge of the dried milk powder, with Techno-G’s ball segment valve taking a leading role in this essential stage.

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Key Role of the Ball Segment Valve

Techno-G’s ball segment valve plays a fundamental role in the discharging process of baby milk powder production. This innovative valve technology offers several key advantages:

- Precise Control: The ball segment valve provides manufacturers with precise control over the flow of dried powder. This precision is the key in maintaining the consistency and quality of the final product. It ensures that the right amount of powder is released, helping to meet product specifications and minimize waste

- Sealing Capabilities: Known by its excellent sealing properties, by means of the Inflatable vacuum seal system, the valve is closing off the vessel while production and drying takes place. It also prevents any risk of contamination during the discharge process. This is of paramount importance in the production of baby milk powder to maintain product purity and hygiene.

- High Wear Resistance: Techno-G’s ball segment valve is engineered for durability and resistant to wear, making it ideal for handling rough or high-temperature materials that may be encountered during the drying process. The wearing materials can be executed in Hastelloy and or Titanium.

- Maintenance and Cleanability: In the food industry, ease of maintenance and cleanability is critical. The valve design allows for ease of disassembly, cleaning, and maintenance, reducing downtime and ensuring hygienic operation, aligning with the strict standards of the food industry.

- Application in Challenging Environments: The valve is capable of performing in demanding environments, including those with high-temperature or corrosive conditions, ensuring longevity and reliability in industrial applications. For higher temperatures as well as highly corrosive applications, Techno-G vales can be executed with FFKM (Perlast) seals to ensure resistance throughout the process application.

Baby milk powder production is not only about efficiently drying the milk mixture but also about maintaining the highest safety and quality standards. Techno-G’s ball segment valve plays a key role in achieving this by providing the control and sealing necessary to keep the final product free from contamination and to guarantee its purity. As the demand for baby milk powder continues to rise, Techno-G’s ball segment valve will keep enabling the industry to meet these demands without compromising on safety or product quality. Its precision control and sealing capabilities make it an invaluable asset in the production of baby milk powder, ensuring that infants receive the nourishment they deserve, free from contaminants and of the highest quality.