The versatile role of ball valves in handling solids and fine chemicals

tim2024-01-26T07:47:10+00:00Ball Segment Valves play an important role across various industries, particularly in the handling of solids and fine chemicals. At Techno-G, we excel in producing high-quality Ball Segment Valves, emphasizing their critical function in operations demanding precision and dependability. We are dedicated to delivering solutions that not only meet but surpass the meticulous standards our clients rely on us to maintain.

Understanding Ball Segment Valves

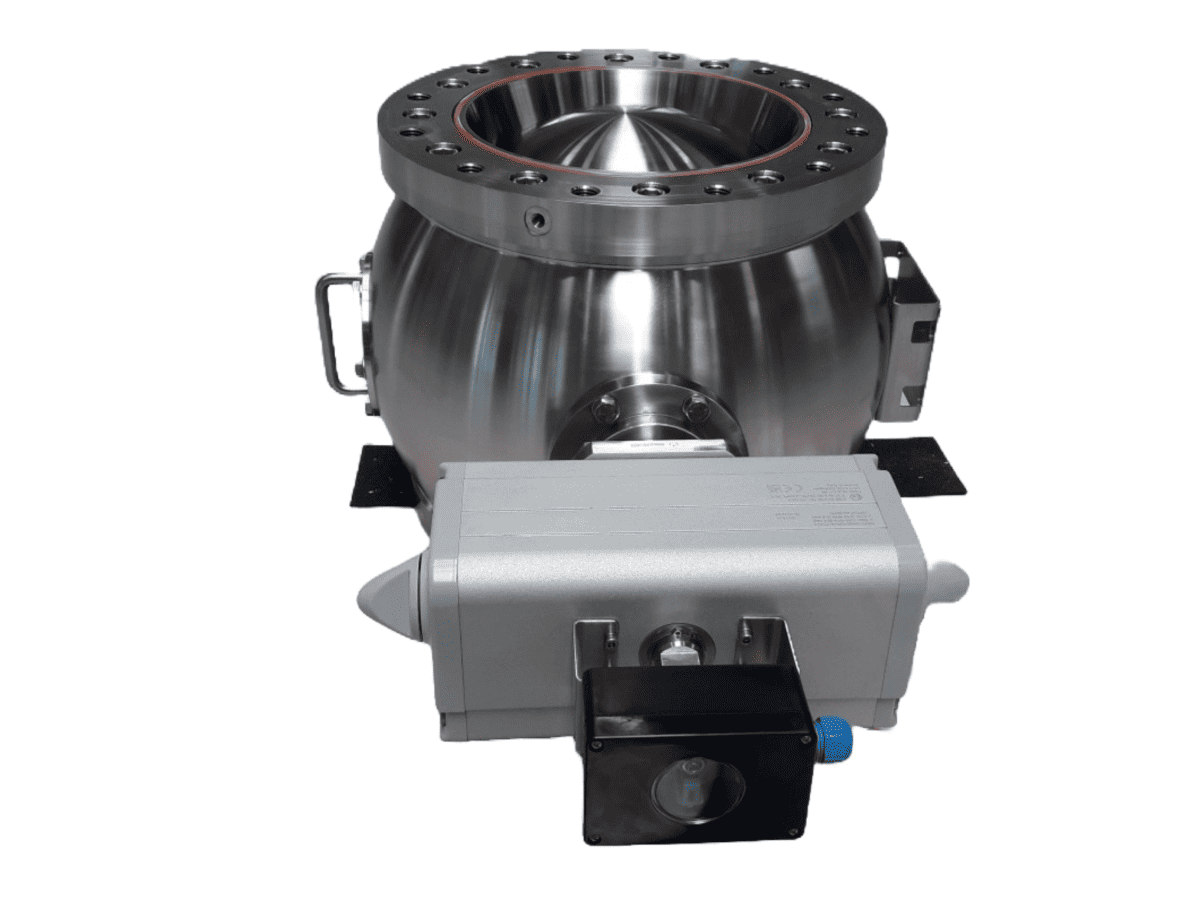

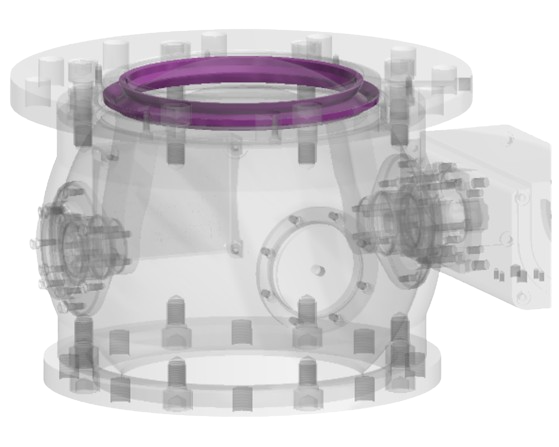

A ball segment valve, at its core, is a device that controls the flow of substances. Featuring a spherical disc, the part of the valve which controls flow through it, ball segment valves are known for their durability and ease of operation. These valves are distinct for their ability to provide bi-directional flow and leak-proof service, making them an ideal choice for various applications.

Key Features and Design

Our Ball Segment Valves are offered in a comprehensive range of sizes, from DN100 to DN450 and ANSI sizes from 4 inches to 22 inches, to accommodate a variety of industrial needs. The full-bore design of the valve housing is essential for applications necessitating minimal pressure drop, ensuring efficient and hygienic flow.

Material Choices

Material is a critical aspect of ball valve design. Common materials include stainless steel and other specialized alloys, which provide resistance against corrosive and erosive substances. For high-pressure applications, robust materials are used to ensure the valve’s reliability.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Applications in Various Industries

Ball Segment Valves are versatile and find applications in several industries. For instance, in the pharmaceutical– and fine chemical industry, they are used for their precision and ability to handle fine solids. Similarly, in the food and cosmetics industries, the hygienic nature of certain ball valves makes them a preferred choice.

Specialized Applications

In the handling of solids and fine chemical materials, ball segment valves offered by Techno-G come into play significantly. Their ability to handle fine solid materials, coupled with innovative features like an inflatable seal, make them ideal for ensuring optimal pressure management in these sectors.

The Techno-G advantage

At Techno-G, the focus is on providing solutions that are not just effective but also efficient. The ball segment valve, a specialized type of ball valve, is designed specifically for handling fine solid materials. This valve stands out for its precision, something crucial in industries like pharmaceuticals and fine chemicals as you might know.

Why choose our valves?

- Full Range with bore openings: from DN100- DN450 mm, fully hygienic design and modular build with options and controlling systems (ook hier kun je hyperlinken)

- Innovative design: The 3D printed titanium valve is a testament to the innovative approach of Techno-G. This design offers unmatched precision and durability.

- Customization options: Understanding that each industry has unique requirements, Techno-G provides a range of sizes and options for their ball segment valves.

- Quality assurance: With a strong emphasis on quality control and certifications, Techno-G ensures that each valve is up to the industry standards.

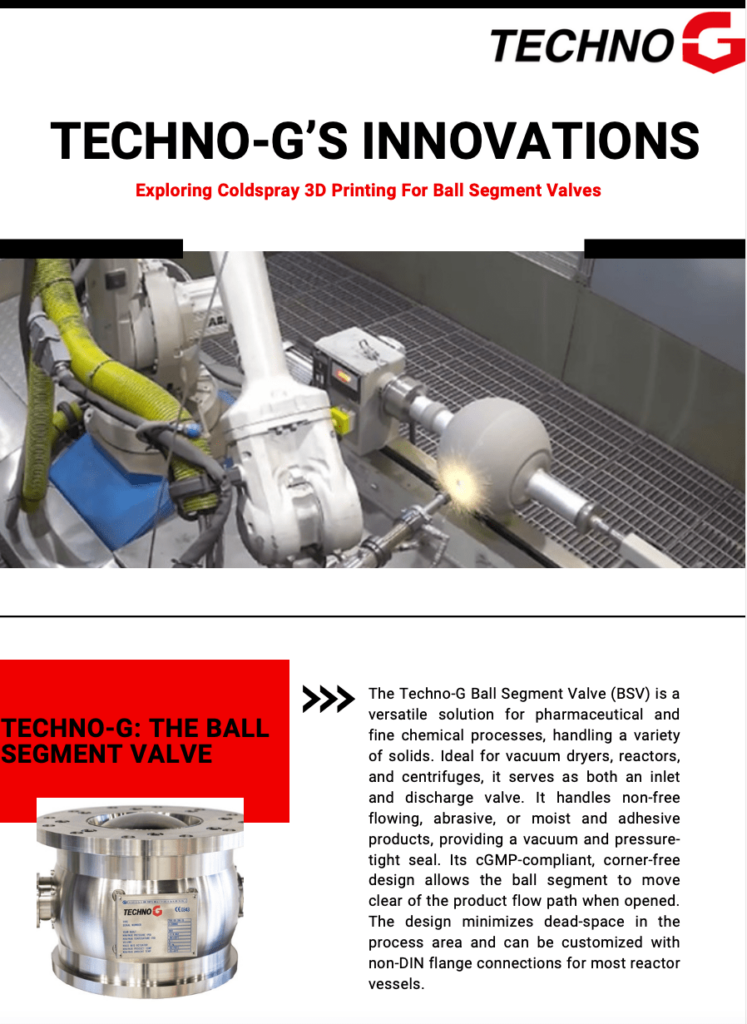

Download our free whitepaper

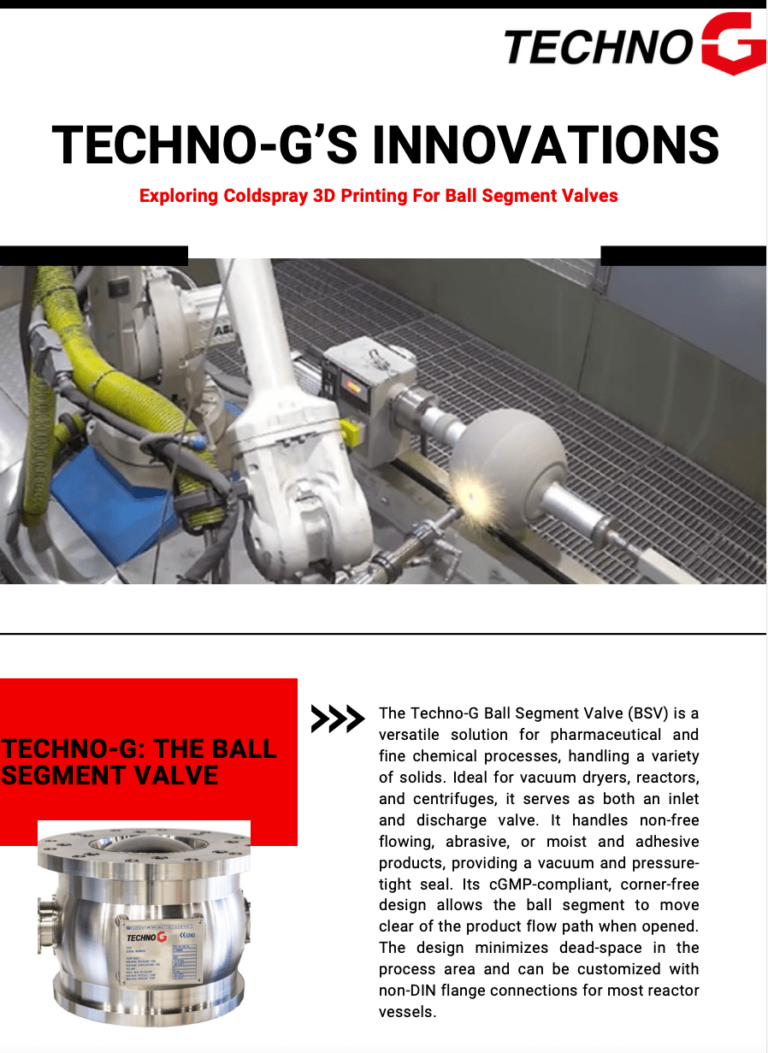

"Exploring Coldspray 3D Printing For Ball Segment Valves"

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Advanced applications and special features

Continuing our exploration into the world of ball valves, let’s delve deeper into the specific applications and unique features of our valves, particularly in handling fine chemicals.

Specialized features for diverse needs

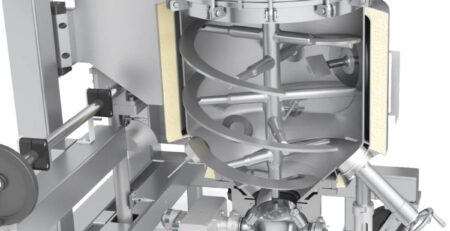

Our Ball Segment Valves are far from standard; they are specially designed to meet the complex needs of a variety of industries. These valves excel in environments where control and modulation of pressure are critical, ensuring consistent and precise management of materials, whether granular or powdery. Their robust construction and design facilitate smooth operation even under varying pressure conditions, making them particularly suitable for applications that require exacting standards of performance.

Enhancing solids handling

In the handling of solids, conventional valves often fall short due to issues like clogging or inadequate sealing. This is where The segmented ball valves come into play. Our valves are designed to provide an optimal solution for fine chemical material handling, ensuring smooth operation even in challenging conditions.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Techno-G’s Commitment to Innovation and Quality

- Innovative sealing technology: The most reliable inflatable seal in the valves ensures a tight closure, essential for maintaining product quality and preventing leaks.

- Customizable solutions: Recognizing the diverse needs of different industries, we offer special executions of ball valves, ensuring that each valve is tailored to specific operational requirements.

- Quality and certifications: Adhering to the highest standards, our products come with comprehensive quality control and certifications, ensuring that each product meets and exceeds industry expectations.

Engage with us for your valve needs

For those interested in learning more about how we can meet their specific valve requirements, the contact page offers a direct line to our expert team. Additionally, our news section keeps you updated on the latest developments and innovations.