Advancing Pharmaceutical and Fine Chemical Processes: The Synergy of Techno-G’s Ball Segment Valve and Cylindro Conical Dryer

tim2024-08-08T14:09:34+00:00Within the rapidly changing domains of pharmaceuticals and fine chemicals, Innovation and Quality serve as the pillars leading to success. Techno-G, a leading provider in cutting-edge solutions, collaborates seamlessly with Bolz-Summix Process Technology, a renowned expert in advanced drying and mixing processes. Together, they present a transformative partnership that optimizes pharmaceutical and fine chemical operations.

Techno-G's Ball Segment Valve: Elevating Precision and Adaptability

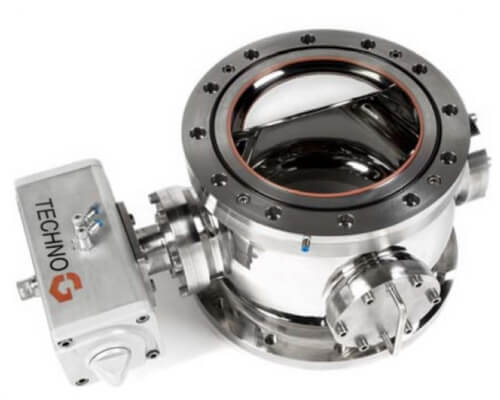

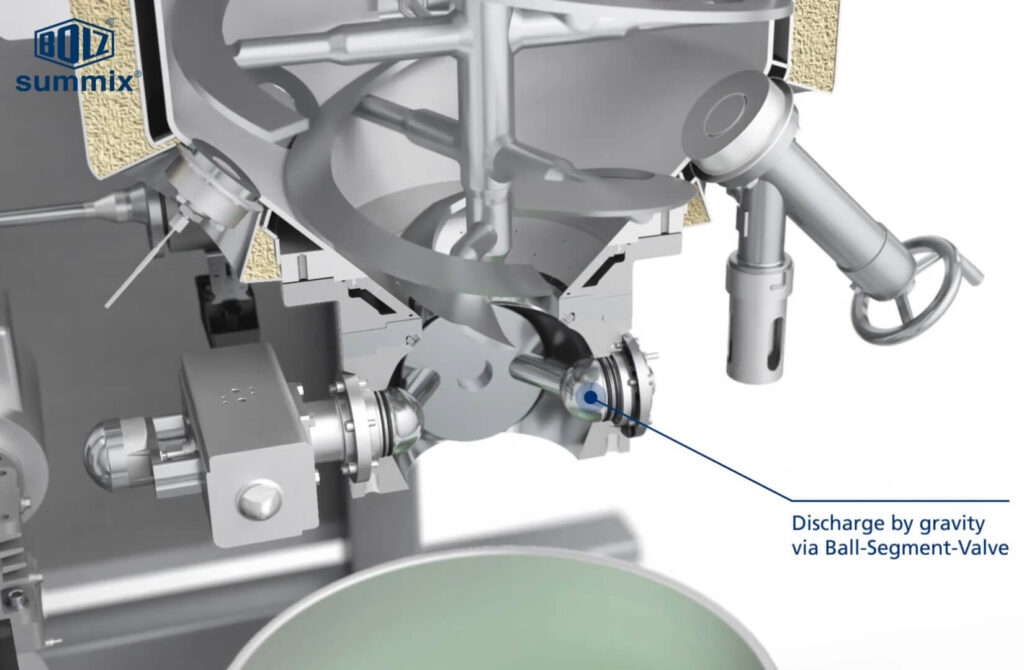

Techno-G’s Ball Segment Valve is a dynamic solution with wide-ranging applications, tailored to meet the unique demands of pharmaceutical and fine chemical processes. Its dual functionality as an inlet and discharge valve makes it an essential component for efficient operations in vacuum dryers, reactors, and centrifuges.

Key Features of Techno-G's Ball Segment Valve:

- Versatility and Adaptability:

In pharmaceutical and fine chemical processes, dealing with a variety of solids is a common challenge. The BSV, with its versatile design, emerges as a reliable solution capable of handling non-free flowing, abrasive, moist, and adhesive products. This versatility ensures seamless operation across different stages of production.

- Dual Functionality – Inlet and Discharge:

The BSV stands out for its dual functionality, serving as both an inlet and discharge valve. This feature is particularly crucial in processes involving vacuum dryers, reactors, and centrifuges, where precise control over material flow is essential for optimal efficiency.

- cGMP-Compliant Design for Regulatory Compliance:

Adhering to current Good Manufacturing Practice (cGMP) standards is non-negotiable in the pharmaceutical and fine chemical industry. The BSV’s corner-free design not only ensures compliance but also minimizes dead space in the process area. This design consideration is pivotal for maintaining the integrity of the production environment and the quality of the final product.Customization for

- Process Optimization:

The Modular system of the BSV allows for customization, providing tailored solutions for vacuum drying and pressurized reactors. The ability to customize non-DIN flange connections further enhances its adaptability to specific reactor vessels. This customization capability contributes to the optimization of individual manufacturing processes.

- Innovative Inflatable Seal for Tight Sealing:

The BSV’s unique inflatable seal, precision-machined to exact tolerances, ensures excellent vacuum and pressure tightness. This feature is paramount for maintaining the desired process conditions, preventing contamination, and ensuring product quality.

- Precision Machining and Bearings for Reliability:

Precision-machined seats and special bearings within the BSV contribute to its exceptional vacuum and pressure-tight seal. This level of precision and reliability is crucial for the demanding requirements of pharmaceutical and fine chemical applications.

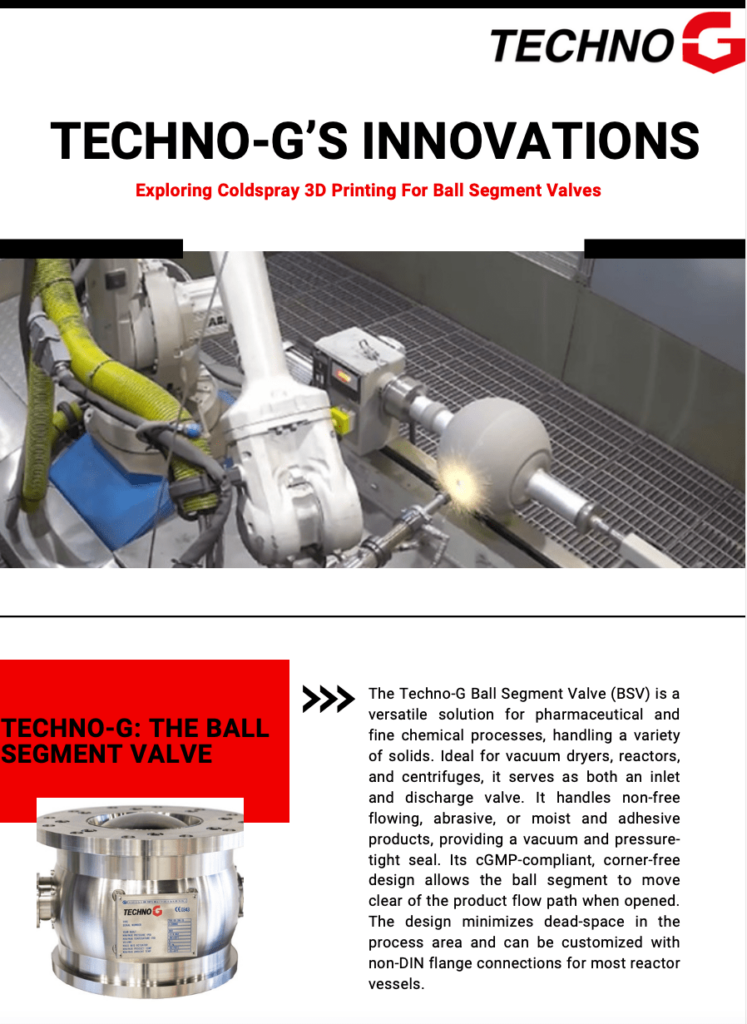

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

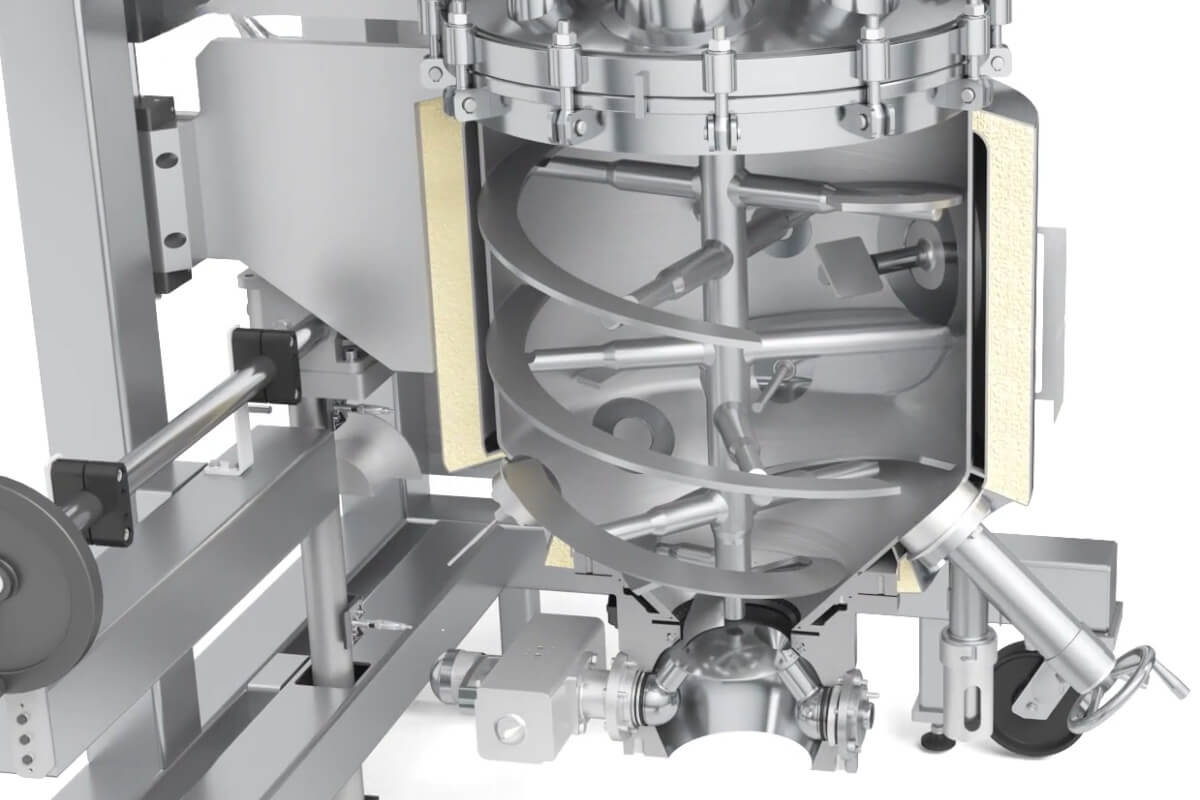

Complementing the precision of the BSV, Bolz Process Technology’s Cylindro Conical Dryer emerges as a game-changer in optimizing product quality through advanced drying and mixing processes.

- Efficient Mixing and Drying:

The CCD’s heated helix agitator ensures short drying times by keeping all batch products in constant motion, eliminating cold spots.

- Versatility and Adaptability:

Accommodating powders, liquids, and pastes, the CCD is suitable for a wide range of applications with variable speed for optimum product quality.

- Space-Saving Design:

The CCD’s compact design offers a significant advantage in terms of equipment footprint, contributing to efficient use of space.

- Excellent Discharging and Heat Transfer:

The CCD excels in discharging and heat transfer, ensuring high-quality end products.

The collaboration between Techno-G’s Ball Segment Valve and Bolz-Summix Process Technology’s Cylindro Conical Dryer creates a powerful synergy in pharmaceutical and fine chemical processes. The precision, adaptability, and innovation embedded in these solutions contribute to enhanced efficiency, quality, and compliance in the dynamic world of pharmaceuticals and fine chemicals. By choosing these state-of-the-art technologies, industries can unlock their full potential and achieve exceptional outcomes in their production processes.