Die Rolle der aufblasbaren Segmentventildichtung bei der Optimierung der Druckleistung

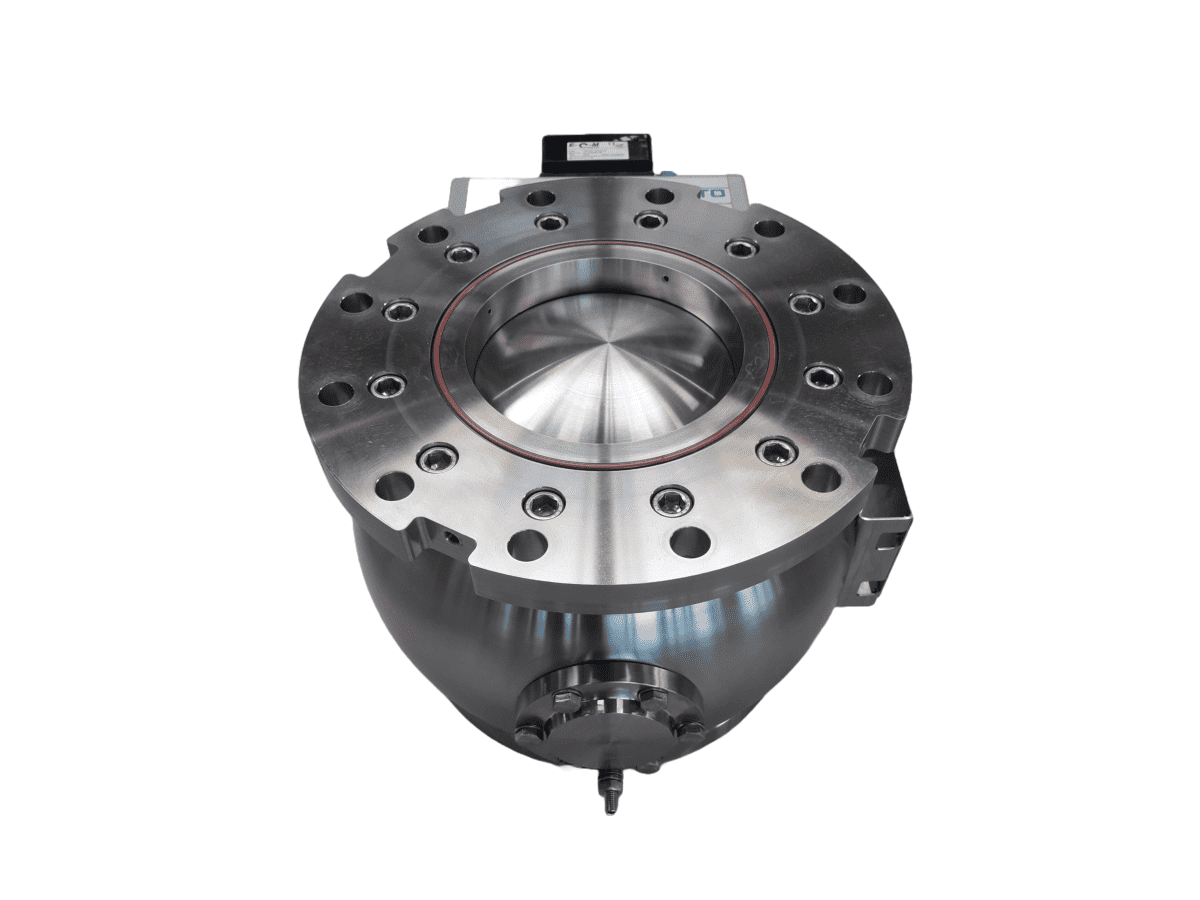

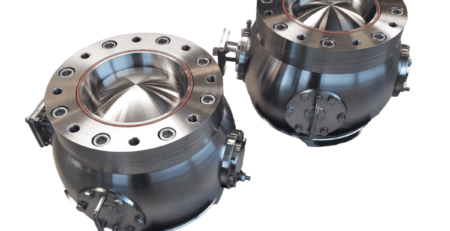

tim2024-03-10T10:28:40+00:00In the world where process automation and materials handling are daily business, the advent of segment valves equipped with inflatable seals represents a significant technological leap. We will explore with you the benefits and applications of our ball segment valve including an inflatable seal, a flagship product offered by us. These valves are meticulously designed for efficient handling of fine solid materials, boasting a reliable inflatable seal crucial for optimal pressure management.

Table of Contents

The innovation behind sealing

At the heart of our product line lies the ball segment valve, a versatile and robust solution for handling solid materials in industries ranging from pharmaceuticals to minerals and many other industries. The key to its unparalleled efficiency and reliability is the inflatable seal. But what makes this seal so special?

The inflatable seal advantage

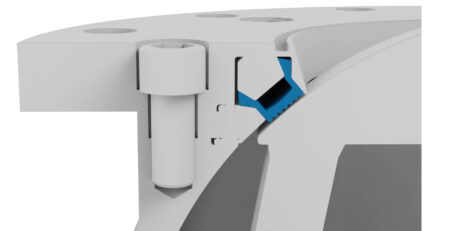

An inflatable seal, like those found in our valves, is designed to offer a flexible yet secure sealing solution. This is particularly crucial in handling delicate processes involving fine powders or granular materials. The seal’s inflatable nature ensures a tight closure, preventing any material leakage and maintaining the integrity of the process.

The adaptability of the inflatable seal makes it suitable for a wide range of applications were maintaining purity, preventing contamination, and managing different pressure levels are essential. In the food industry, for instance, it ensures sanitary conditions by preventing product build-up and residues. Similarly, in chemical industries, the chemical resistance of the seal materials guards against corrosive damage, ensuring a long service life.

SPEZIFIZIEREN SIE EIN TECHNO-G VENTIL FÜR IHRE ANWENDUNG

SPEZIFIZIEREN SIE EIN TECHNO-G VENTIL FÜR IHRE ANWENDUNG

Enhanced performance and reliability

One of the standout features of our ball segment valves is their capability to manage air pressure effectively. The inflatable seal, when expanded, creates a pressure-tight barrier, which is essential in processes involving air-sensitive or heat-sensitive materials.

Customization options

At Techno-G, we understand that every application has unique requirements. That’s why our ball segment valves can be tailored to your specific needs using a range of customizable options. From different materials for the housing, the inflatable seal (material options: EPDM White, EPDM Black, Viton White, Viton Black and Perlast FFKM), and sizes up to DN450, these valves can be tailored to meet many industrial demands.

Operational efficiency

Incorporating an inflatable seal into the valve design significantly enhances the valve’s operational efficiency. It reduces wear and tear, minimizes downtime for maintenance, and ensures a smooth flow of materials through the full-bore design. This efficiency is not just about the product’s longevity but also about the efficiency in product processing, ensuring minimal disruption in the workflow.

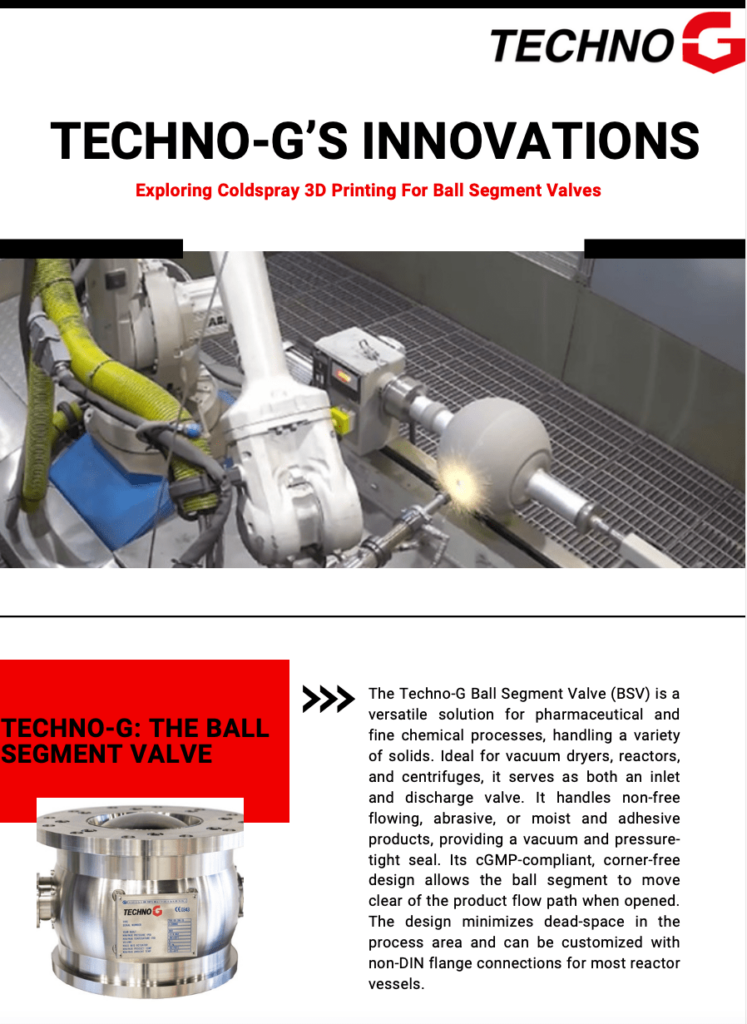

Laden Sie unser kostenloses Whitepaper herunter

"Erforschung des 3D-Drucks mit Kaltgasspritzen für Kugelsegmentventile"

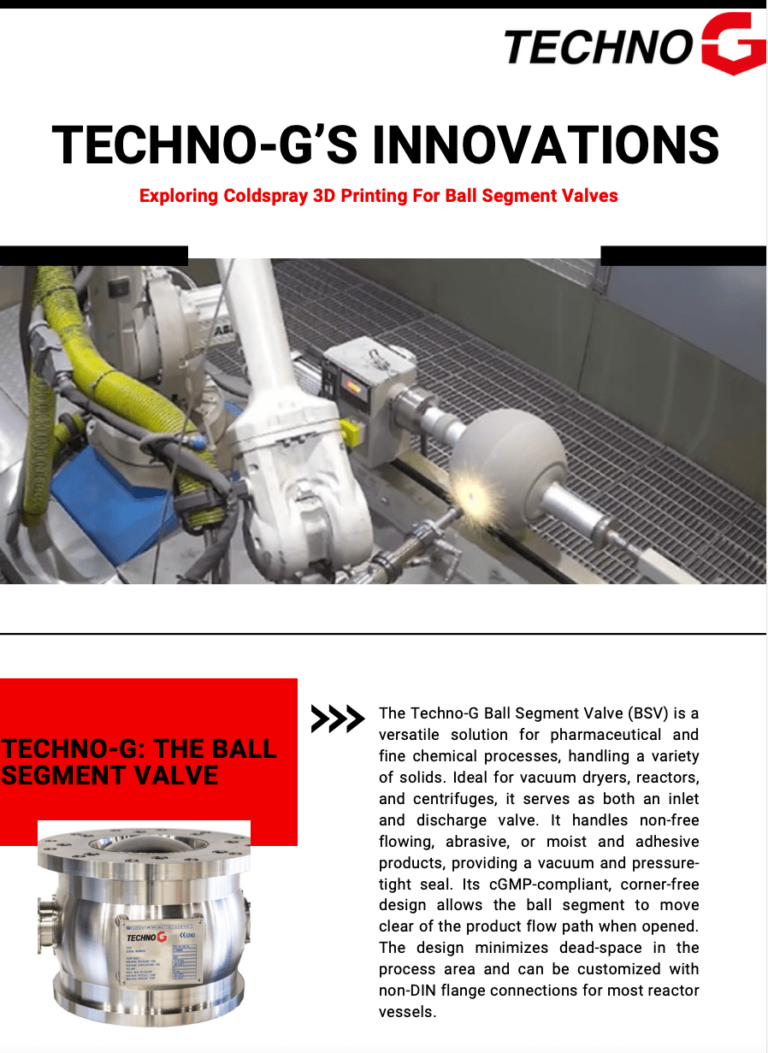

Das Techno-G Kugelsegmentventil (BSV) ist eine vielseitige Lösung für pharmazeutische und feinchemische Prozesse, die eine Vielzahl von Feststoffen handhaben. Es ist ideal für Vakuumtrockner, Reaktoren und Zentrifugen und dient sowohl als Einlass- als auch als Auslassventil. Er verarbeitet nicht frei fließende, abrasive oder feuchte und klebrige Produkte und bietet eine vakuum- und druckdichte Abdichtung. Das cGMP-konforme, eckenfreie Design ermöglicht es dem Kugelsegment, sich beim Öffnen aus dem Produktflussweg zu entfernen. Die Konstruktion minimiert den Totraum im Prozessbereich und kann mit Nicht-DIN-Flanschanschlüssen für die meisten Reaktorbehälter angepasst werden.

Das Techno-G Kugelsegmentventil (BSV) ist eine vielseitige Lösung für pharmazeutische und feinchemische Prozesse, die eine Vielzahl von Feststoffen handhaben. Es ist ideal für Vakuumtrockner, Reaktoren und Zentrifugen und dient sowohl als Einlass- als auch als Auslassventil. Erfahren Sie mehr.

Meeting CGMP and industry standards

In industries where compliance and standards are non-negotiable, such as pharmaceuticals and high-end food processing, valves rise to the occasion. Segment valves, especially designed to meet CGMP requirements, ensure that the handling of sensitive materials like baby milk powder or pharmaceutical products is done with the utmost precision and safety. The valves‘ construction materials and design minimize the risk of contamination, making them a preferred choice in these sectors.

Addressing unique challenges

Each industry faces its own set of challenges. For instance, in the chemical industry, dealing with aggressive substances requires chemical resistant and inert materials. Similarly, in the metal powder and minerals industries, handling abrasive products demands robust designs to prevent excessive wear. Our ball segment valves, with a range of seal materials and construction options, provide tailored solutions for these demanding applications.

In handling fine materials, consistent product flow is crucial. With spherical disk design and inflatable seals, we ensure an unobstructed product discharge, preventing issues like product jamming or build-up. This seamless flow is critical in maintaining operational efficiency and reducing downtime in processes.

WENDEN SIE SICH AN UNSER EXPERTENTEAM FÜR IHRE ANFRAGEN

Techno-G's commitment to excellence

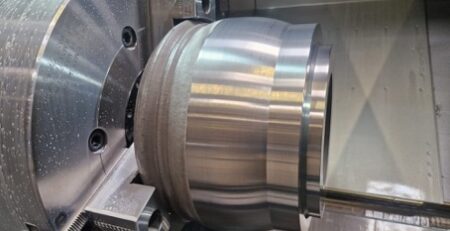

Quality is at the forefront of our manufacturing process. Each valve undergoes rigorous quality control and certification processes to ensure that they meet the highest standards of performance and reliability. This commitment to quality is reflected in the valves‘ long service life and efficient operation, even in severe process applications.

A partner in innovation

We are more than just a supplier; we are a partner in innovation. Our expertise in handling a multitude of applications and commitment to providing reliable solutions makes us a valuable ally in various industries. Whether it’s retrofitting existing systems with advanced valves or exploring new applications, at Techno-G, we are at the forefront of innovation in valve technology.

The first step

Our ball segment valves, including inflatable seals, represent a convergence of innovation, quality, and versatility. These valves are not just components; they are critical solutions that enhance the efficiency, safety, and reliability of industrial processes across a wide range of sectors. For more information on how these valves can transform your operations, explore every detail of our outstanding product or discover specific industry applications. Take the first step towards optimizing your process by requesting a quotation or contacting our team at Techno-G. Let us help you elevate your process with the power of innovation and quality.