Dryer valve function in drying chemical substances

tim2024-01-26T07:40:58+00:00Dryer valves are indispensable in efficient drying of fine chemical substances. These components are essential in industries like pharmaceuticals, chemicals, and high-end food processing, where precision and reliability are paramount. Keep reading to discover the function of the dryer valve in various applications.

The essence of dryer valves

A dryer valve, often a component in an appliance like a paddle dryer, is designed to regulate the flow and pressure of solids and materials within drying systems. In a typical drying process, the valves usually control the release of solid substances. These types of valves are essential in ensuring that the drying process is conducted efficiently and safely.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Different valves for dryers

There are various types of dryer valves, including smaller direct acting valves and pass valves. Each type has its specific role, whether in controlling flow rates or operating under different pressure conditions.

Selecting the right valve

When choosing a valve for a dryer, several factors must be considered:

- Model compatibility: Ensure the valve is compatible with your drying equipment. Our compact ball segment valves are designed to fit a variety of machines and can be designed to meet your special requirements.

- Valve specifications: Understanding the valve’s capabilities is crucial. At Techno-G, we ensure every ball segment valve is robustly produced to meet stringent conditions and mandatory industry standards

- Professional technician assessment: Consulting with a professional technician can help in making the right choice. Feel free reaching out to us to discuss your needs.

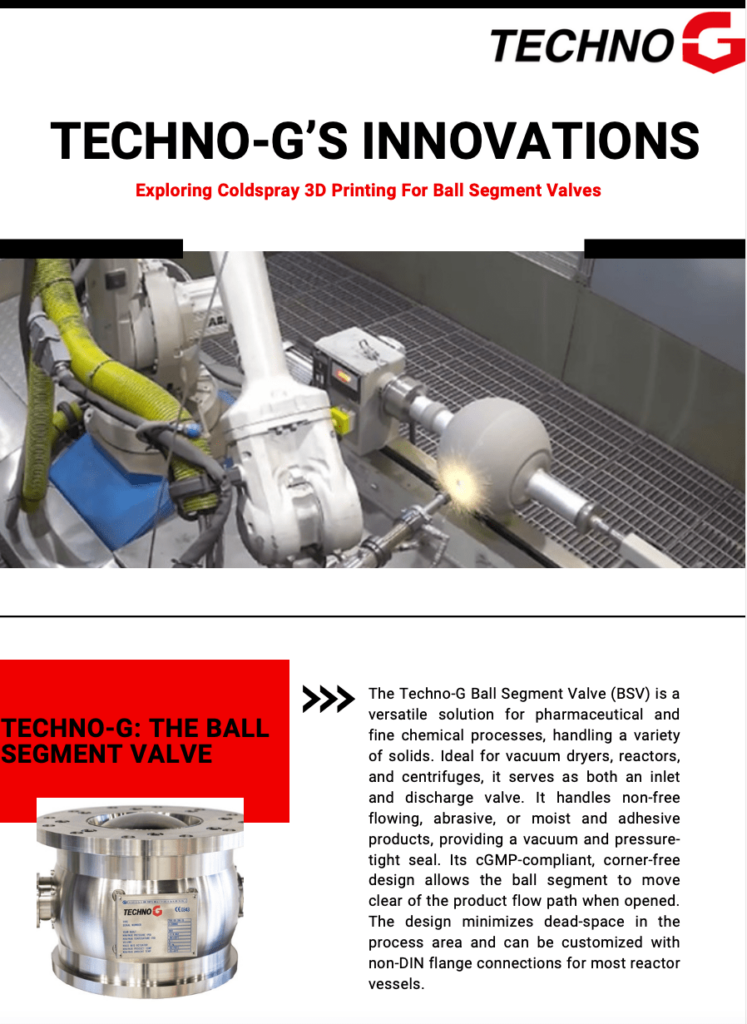

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

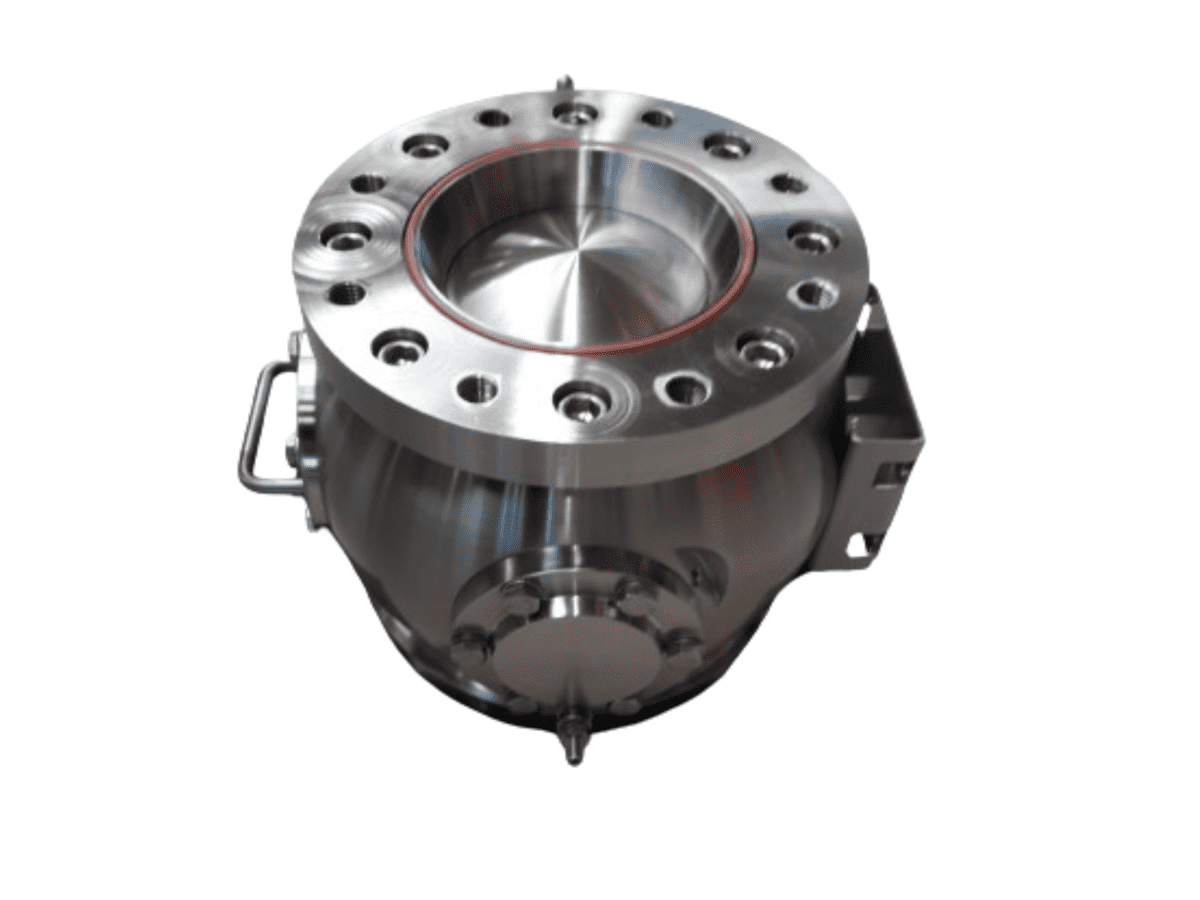

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Where we stand out for

Our valves offer precision and reliability. They are not suited for fluid handling but excel in solid material applications. This makes them ideal for industries like pharmaceuticals, cosmetics, chemicals, minerals, and other industries.

Why choose our valves?

- Quality and durability: Our valves are designed for long-term use, delivering optimal performance in high- and low temperature environments, that’s why we prioritize quality above quantity.

- Innovative features: The inflatable seal in our valves provides optimal pressure management, essential in the drying of chemical substances.

- Customization: We offer a range of customization options, including different components for specific needs.

Advanced features

Continuing our exploration of valves for drying systems, it’s important to delve into the advanced features that set Techno-G valves apart, particularly when dealing with fine chemical substances.

- Enhanced material handling

Our ball segment valves, with full bore opening, are specifically designed for handling fine solid materials. This is particularly important in industries such as pharmaceuticals and minerals, where the handling of powders and granules requires precision and care.

- Inflatable seal technology

One of the standout features of our valves is the innovative inflatable seal. This seal provides optimal pressure management, ensuring that the valve closes tightly and prevents any material leakage or contamination, even in corrosive hazardous enviroments.

- Customization and options

We understand that different applications require different solutions. That’s why we offer a range of size options and special executions to fit various requirements and systems.

- Tailored to your industry needs

Our valves are not a one-size-fits-all solution. For instance, in the food industry, where hygiene and safety are paramount, our valves are designed to meet stringent standards. Similarly, in the cosmetics industry, our valves handle delicate substances with the required gentleness and precision.

Technological innovation

Techno-G is at the forefront of valve technology. Our 3D Printed Titanium Valves are a testament to our commitment to reliability, offering unparalleled strength and durability.

In today’s fast-paced industrial environment, the need for dependable and efficient valve solutions is more critical than ever. Our valves, with their advanced actuators, meet these demands, providing quick and accurate control.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Our commitment to excellence

At Techno-G, our commitment to excellence is reflected not only in our products but also in our comprehensive customer support.

Continuous Innovation and Improvement

We are continuously improving our products, as seen in our newest video animation showcasing the functionality and advantages of our valves. This dedication to innovation ensures that our valves remain at the forefront of industry standards.

A sustainable future

Techno-G is committed to sustainability. Our valves are designed to be long-lasting, reducing the need for frequent replacements and thus contributing to a more sustainable industry practice.

Wrapping up

The role of a dryer valve in drying fine chemical substances cannot be overstated. Our valves, with their precision, reliability, and full bore design, are an ideal choice for industries where quality and efficiency are crucial. Explore our full range of valve options and discover how they can enhance your drying processes.