Chemicals valves in handling operations

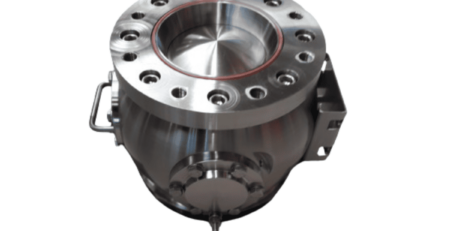

tim2023-09-12T11:29:09+00:00Today, we delve deep into the heart of fine chemicals processing – the chemicals calve. This isn’t just any valve, but a ‘fine’ one made for the handling and processing of fine chemical substances. And when we say fine, we mean exquisite, like the quality of our segmented ball valves featuring an inflatable seal, engineered for solids handling.

Why are chemical valves so important?

Process safety

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Types of valves used

The variety of applications in our industry necessitates a variety of valves. Gate valves, butterfly valves, ball valves, including the segmented ball valves from Techno G are among the common types. Each type has its advantages – like the advantage of the globe valves in adjustment of the flow of fluid, or the diaphragm valves in fluid contact material situations.

The choice of valve depends on factors such as nominal pressure, operating pressure range, fluid flow, and even environmental conditions. Each valve brings something unique to the table. For instance, 3-way chemical valves are excellent for situations requiring flow control angle seat or switching of valves.

The magic of the segmented ball valves

Resistance: The key for survival

Working with chemicals, there’s no avoiding corrosive or abrasive materials. Valves must have a high level of resistance. Material selection, such as stainless steel valves or elastomer valves, plays a significant role in a valve’s corrosive resistance and overall chemical resistance. Techno G’s valves are designed to withstand a wide variety of applications and offer impressive resistance, even against sulfuric acid!

Ensuring smooth flow

The ultimate goal of a process engineer is to achieve a smooth flow. Flow rates, loss of pressure, or pressure drop can make or break the process. Valves like Techno G’s help ensure this smooth flow, even in challenging conditions like 100 mm pressure or 40 bar – valve function scenarios.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Innovations within the fine chemicals industry

In recent years, the fine chemicals industry has been marked by a slew of innovations that have revolutionized the way these substances are processed and handled. Driven by the need for increased efficiency, safety, and precision, these advancements have redefined the boundaries of what is achievable in this dynamic sector.

Moreover, advancements in automation and control systems have further boosted the performance of the specialized fine chemicals valves. Today’s fine chemical valves can be monitored and adjusted remotely, providing real-time data that can be used to optimize production processes.

In addition, there has been a significant push towards developing valves that are more durable and require less maintenance. The use of new materials and innovative designs has resulted in valves that can withstand the harsh conditions often found in fine chemical processing, leading to longer operational lifetimes and lower overall costs.

These innovations within the fine chemicals industry reflect a growing commitment to utilizing technology to overcome challenges and drive progress. As the industry continues to evolve, the importance of high-performing, reliable, and efficient fine chemicals valves is more critical than ever.

The valve for fine chemical operations

A fine chemicals valve is crucial in the processing and handling of fine chemical substances. The right valve ensures smooth operation, safety, and efficiency. The variety of valves available caters to a wide range of service conditions and process control needs.

Techno G’s segmented ball valves with their unique inflatable seal are an excellent example of a valve that’s designed for optimal performance and longevity. Our valves ensure a high level of resistance against corrosive materials and smooth flow under various conditions, making them a vital asset for any process engineer.

As a process engineer, choosing the right valve could mean the difference between a smooth operation and a potential disaster. After all, no one wants an unexpected 1910.119 – Process Safety Management situation on their hands. So, here’s to making the right choice – because in the world of fine chemicals, the devil is indeed in the details!