Techno-G has a unique CIP cover for the entire Ball Segment Valve Range!

Techno-G always opts for a "rotating CIP head" because it provides complete coverage within the entire housing and effectively reaches even the dead corners. Cleaning in Place (CIP) in the Pharmaceutical Industry: CIP is a process used to clean equipment and pipeline systems without disassembly. In the pharmaceutical industry, it is critical...

Hard Inchromising for Ball Segment Valve Heads

In the (petro)chemical, pharmaceutical, and food industries, high-quality stainless steel alloys and nickel-based materials are frequently utilised. Although the choice of these materials may seem straightforward, they are unfortunately susceptible to corrosion and wear under certain conditions. When these materials are used in dynamic components, conventional techniques and materials often fall...

Paddle Dryer vs. Conical Dryer – A Technical Comparison

In the chemical and pharmaceutical industries, selecting the right dryer is critical for ensuring product quality, stability, and manufacturing efficiency. Among the most commonly used types of dryers are Paddle Dryers and Conical Dryers. Both are designed to handle drying under challenging conditions such as high pressure and vacuum, and...

Techno-G Expands Material Options for Ball Segment Valves

At Techno-G, our Ball Segment Valves are now available in a variety of advanced material configurations to meet the specific requirements of your applications. Whether you're dealing with highly corrosive environments or high temperatures, we have the right material solution to ensure optimal performance and longevity. Our Material Options: We understand...

Nitrogen Purge Flange

Nitrogen Purge Flange – A Solution to Prevent Blockages

At Techno-G, we would like to highlight our Nitrogen Purge Flange as an option to prevent product blockages in ball segment valves. This addition to the valve system can be useful in processes where dry products tend to build up, potentially leading...Segment valve features and common applications

Segment valves, a cornerstone of industrial technology, are embraced for their versatility and efficacy in handling a variety of materials, especially fine solid materials. Let's delve into the distinct attributes of segment valves and their wide range of applications.

Table of Contents

Understanding segment valves

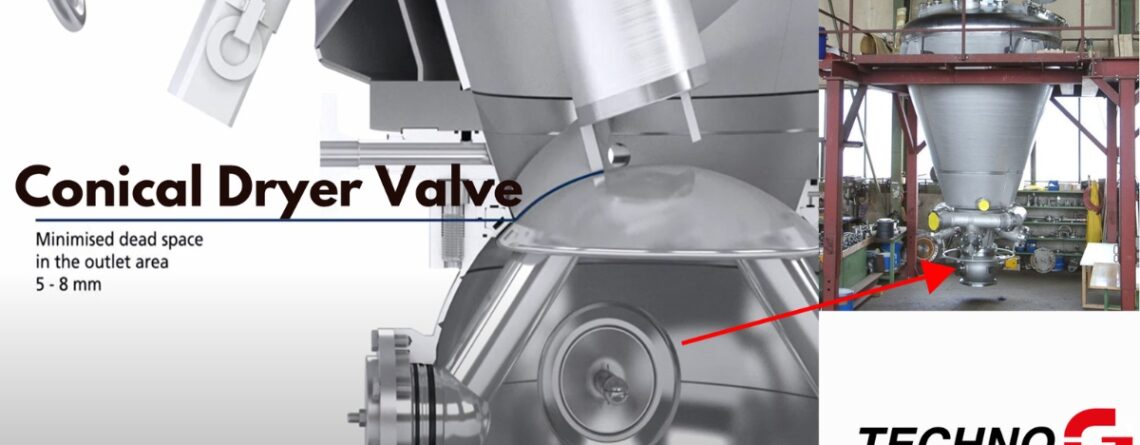

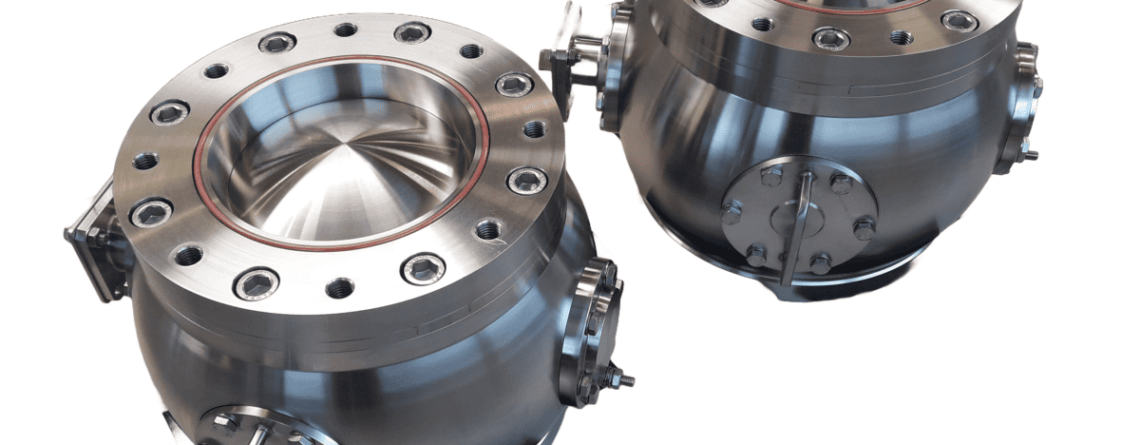

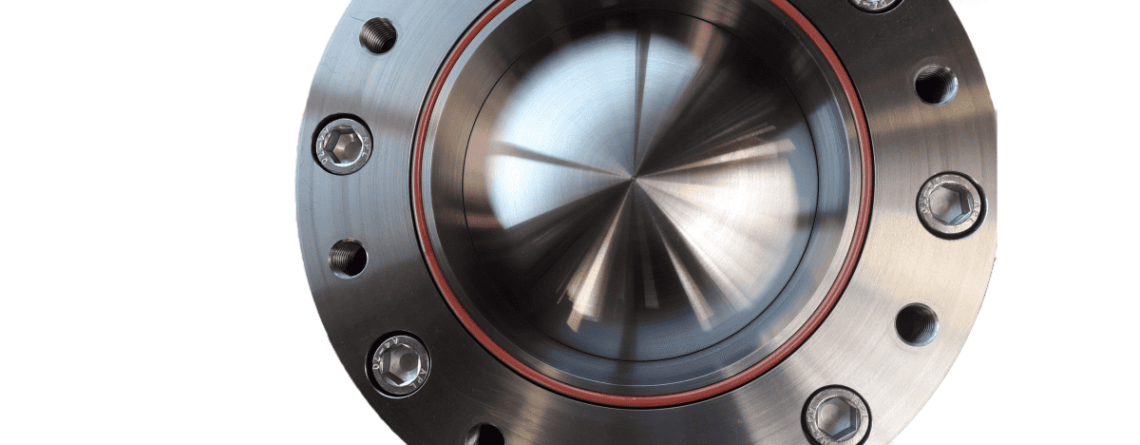

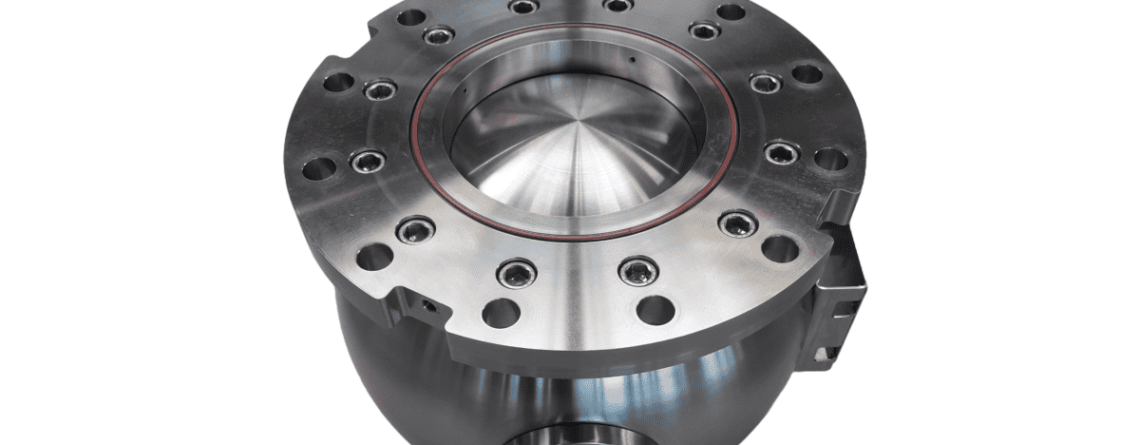

A segment valve, often referred to as a...The conical dryer valve: Key to efficiency

In the dynamic world of industrial drying, the conical dryer valve stands as a pinnacle of innovation and efficiency. At Techno-G, we specialize in ball segment valves, renowned for their precision in handling fine solid materials. However, when it comes to the specific area of solids handling processes, these...

Segment valve inflatable seal’s role in optimizing pressure performance

In the world where process automation and materials handling are daily business, the advent of segment valves equipped with inflatable seals represents a significant technological leap. We will explore with you the benefits and applications of our ball segment valve including an inflatable seal, a flagship product offered by us....

What makes a valve suitable for a conical dryer application?

When looking closely at drying systems in many industries, you'll find a lot of dryer valves. Yet, among these valves, typically suitable in the application for Conical Dryers, holds a unique stature. But what sets it apart? Let’s dive into the world of conical dryer valves, the innovations brought by...