Techno-G’s segmented solids Ball Segment Valve solution for bulk handling

tim2023-09-20T15:07:20+00:00Are you on a hunt for a high-performance valve for your operation? Look no further than the Ball Segment Valve, specifically the Techno G’s segmented ball valve designed for efficient bulk material handling. Working across a variety of industries such as Pharmaceuticals, Chemicals, Fine chemicals, API, Food, Cosmetics, Minerals, and Metals, we deliver a quality performance with its cutting-edge products. This includes a unique inflatable seal that guarantees superior sealing and exceptional control valve performance.

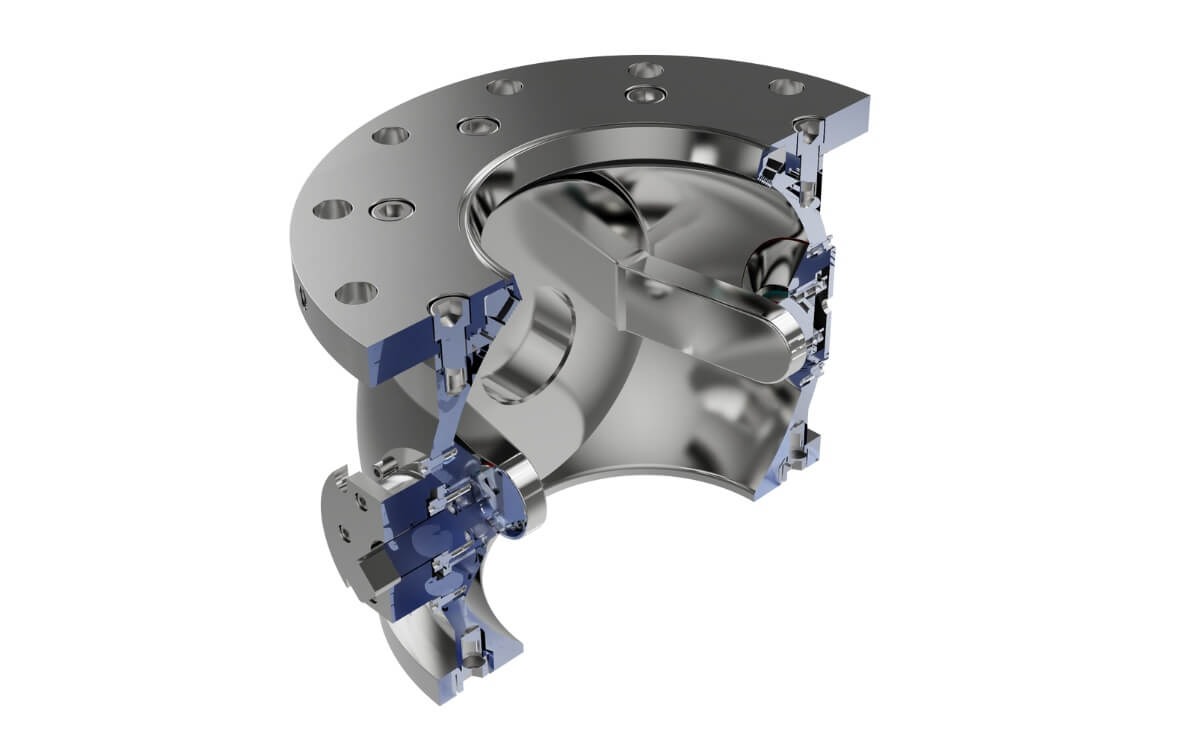

Understanding the segmented ball valve

Let’s first understand what we mean by a segmented ball valve. This specific type of ball valve utilizes a ball segment that has sufficient space and a center flow path, enabling it to handle a flow of solids, even in challenging service conditions. The ball valve control mechanism operates with rotary motion, ensuring a smooth operation, and can handle demanding applications, including abrasive slurry applications. Specifically, de full bore opening of the valve which can vary between 100 mm all the way up to 450 mm! is a unique feature of the Ball Segment Valve from Techno-G!

Ball valve design and components

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Key features of the segmented solids valve

When it comes to handling bulk material, efficiency, and reliability are paramount. Recognizing these needs, Techno-G has engineered a truly remarkable piece of equipment: the Segmented Solids Valve. This valve is crafted with distinct features, each designed with meticulous precision to ensure optimal performance. Whether in the face of corrosive fluids or aggressive slurries, this valve outperforms its counterparts and stands strong. It’s a testament to Techno-G’s innovative spirit and dedication to quality. Let’s delve into the key features that make the Segmented Solids Valve the go-to solution for bulk handling.

- Inflatable Seal: One of the key distinguishing features of Techno G’s segmented ball valve is the inflatable seal. This seal offers excellent sealing performance, ensuring that there are no potential leak paths and that the valve seat is well protected. This means that even in the presence of corrosive fluids or aggressive slurry services, the valve functions optimally.

- Advanced Material Selections and Coating Technologies: The valve boasts advanced material selections, Such as stainless steel, Hastelloy and or Titanium, along with advanced coating technologies. These materials are chosen for their application-specific corrosion and erosion resistance, ensuring the valve can handle even the most erosive services. The coatings, including customized ultra-hard coatings, also prevent body wall erosion and protect the bearings from ingress.

- Balanced Seat Design: A balanced seat design ensures that the valve can handle differential pressure effectively. It provides automatic pressure relief design, adding to the valve’s anti-scaling performance and its excellence in quality performance.

- Adjustable Shaft Seal and Anti-Blowout Stem: These valves also feature an adjustable shaft seal and a blowout-proof stem. These two features work hand in hand to ensure the safety and longevity of the valve. The adjustable shaft seal prevents excess corrosion and the blowout-proof stem protects the internal components.

- Hygienic design: 100% Hygienic design and cleanability to CIP clean the unit inside while being in closed modus.

- Easy Maintenance: The simple design of the segmented ball valve allows easy access for seat maintenance. The routine maintenance is further simplified by the clean stem and clean seat spring features, which prevent dirt accumulation and promote clean products.

Benefits of segmented ball valves for bulk material handling

Segmented ball valves are the perfect solution for the efficient flow of production compounds, thanks to their flow capabilities, flow capacity, flow characteristics, and flow range. They’re a valuable tool in powder industries that deal with the flow of Fine chemicals, flow from bins, Pharmaceutical industry and even flow in the paper industry.

Their durable construction also ensures a long service life, making them an economical product in the long run. They offer excellent seal performance even under severe erosion conditions. Plus, with Techno G’s distinctive inflatable seal, the sealing surfaces are kept clean, enhancing the valve’s resistance for valve internals.

Selecting the right actuator

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

The role of high-performance coatings and bearing seals

High-performance coatings play a vital role in the longevity and performance of segment ball valves. Coatings offer enhanced corrosion resistance and erosion-resistant trim components. Meanwhile, sliding rotational seals, as wel as static seals in Viton, PTFE (FKM), NBR and even Perlast (FFKM) protect the internal components from damage and contamination.

Maintenance and customer service

Conclusion

If you’re looking for a versatile, durable, and efficient valve, consider the segmented solids valve from Techno G. From its advanced material selections to its innovative inflatable seal, this valve is designed to provide you with optimum performance and durability.

So, process engineers, gear up for a significant improvement in your bulk material handling with Techno G’s advanced products that are known for their quality performance. With their customer-focused approach, be rest assured to get the best solution for your application requirements. Their segmented ball valves are more than just a valve; they’re an application-specific solution for your process engineering needs.