Segmented ball valves: Advantages over conventional options

tim2023-09-12T11:28:43+00:00As a process engineer, you understand the importance of selecting the right valve for your industrial applications. One valve design that has gained significant popularity in recent years is the segmented ball valve.

In this article, we will explore the advantages of segmented ball valves over conventional ball valves and how Techno G, a leading manufacturer known for their extraordinary quality segmented ball valves, provides innovative solutions for a wide range of industries. Whether you work in the pharmaceutical, chemical, food, or any other sector, understanding the benefits of segmented ball valves can help you optimize your processes and improve efficiency.

What is a segmented ball valve?

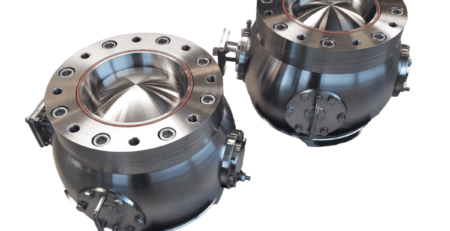

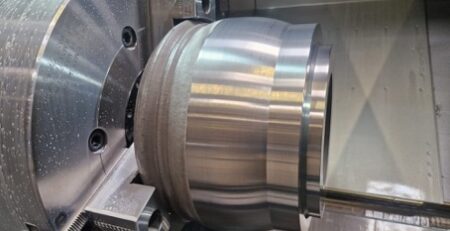

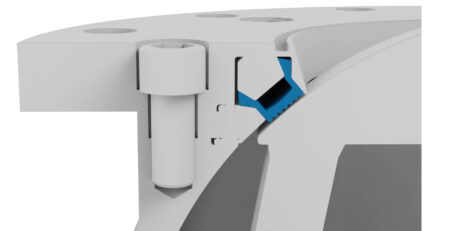

A segmented ball valve, also referred to as a ball segment valve, is a distinctive type of valve that incorporates a segmented ball as its closure component. In contrast to a traditional ball valve, which employs a solid ball, the segmented ball valve consists of multiple contoured segments that merge together to create a spherical shape when closed. This innovative design delivers several advantages over conventional options.

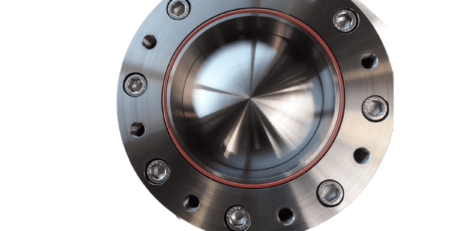

The segmented ball valve enables precise control over the flow of liquids or gasses, allowing for enhanced modulation and regulation of the process. The segmented ball’s contoured surface provides excellent sealing capabilities, ensuring a tight shut-off and minimizing the risk of leakage. This results in improved process efficiency and reduced energy consumption.

Parts of the innovative valve

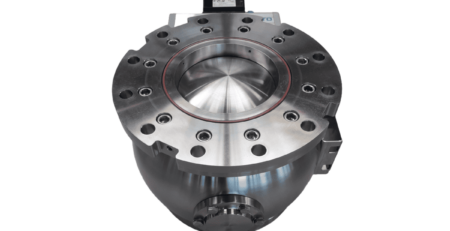

The segmented ball valve comprises several key components that work together to ensure efficient operation. The valve body serves as the main structure, housing the other components. Soft seats, made of resilient materials, provide a tight seal around the ball segments, enhancing sealing performance. The outlet flange enables connection to the desired piping system, while the flange connection ensures a secure and leak-free joint. The valve housing encapsulates the ball segments and supports their movement within the valve body.

With its innovative ball valve design, the segmented ball valve offers precise control and reliable sealing, making it an ideal choice for various industries requiring optimal flow regulation and efficient process management. The inflatable seal, within this ball valve, ensures a secure closure, enhancing safety and reliability, particularly in challenging vacuum-based applications.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

The advantages of segmented valves

Segmented ball valves offer a range of advantages that set them apart from conventional ball valves. With their unique design and engineering, segmented ball valves provide superior performance, enhanced control, and improved reliability in various industries and applications. From precise flow modulation to better sealing capabilities, segmented ball valves offer numerous benefits that contribute to optimized processes and increased operational efficiency. In the following bullet list, we highlight some key advantages of segmented ball valves over their conventional counterparts:

- Superior reliability: The ball valve exhibits superior reliability, even in demanding operating conditions. The segmented design allows for flexibility and compensation of any potential deformations or misalignments, enhancing the valve’s overall performance and longevity.

- Enhanced control and efficiency: Segmented ball valves offer advanced control and efficiency, making them an attractive option for demanding applications. The design of these valves allows for precise control over the flow, making them ideal for applications that require accurate regulation of fluid or gas. With the ability to handle differential pressures and medium consistency applications ranging from 8-19%, segmented ball valves provide excellent flow capacity and performance.

- Superior sealing performance done by segmented ball valves: One of the key advantages of segmented ball valves is their excellent sealing performance. Techno G’s segmented ball valves feature inflatable seals that ensure a leak-free operation, even in abrasive slurry applications. The inflatable seal provides a protected sealing area, preventing potential leak paths and ensuring long-term, reliable sealing. This innovative sealing solution minimizes the risk of product contamination and reduces costs associated with valve repairs and maintenance.

- Erosion-resistant trim components: In applications involving abrasive products or difficult fluids, segmented ball valves excel. With advanced materials and manufacturing, our valves endure erosive effects, extending life and reducing downtime for cost-effective operations.

- Flexible shutoff options: Segmented ball valves offer adjustable sealing for precise control in on-off and flow control applications. With a shearing action and percentage flow characteristic, they are an ideal control ball valve solution. Commonly used in the manufacture of tissue products, segmented ball valves excel as capacity control valves, discharge valves, and flow control valves.

Reduced maintenance and costs

Segmented ball valves also provide cost efficiency in multiple ways. Firstly, their exceptional control valve performance helps optimize processes, leading to improved overall efficiency. The precise control and on-off capabilities of segmented ball valves enable you to achieve the desired process conditions with minimal energy waste. Additionally, the durable construction of segmented ball valves, including live-loaded metal seats and erosion-resistant trim components, reduces the need for frequent repairs and maintenance. This results in significant cost savings in the long run.

Techno-G serves a wide range of industries

Techno G’s segmented ball valves find applications across various industries, including pharmaceuticals, chemicals, fine chemicals, API, food, cosmetics, minerals, metals, and more. Whether you require a control valve solution for critical applications or a valve design suitable for demanding environments, segmented ball valves offer a wide range of options to meet your specific requirements. Their balanced seat and backlash-free torque transmission ensure reliable performance even in the most challenging conditions.

Tailored solutions for your specific needs

Segmented ball valves come in various series and configurations, offering a wide variety of options to meet specific application requirements. At Techno-G, we provide unique segmented ball valves to your specific needs. Whether you require a compact wafer version for space-restricted installations or a double flange body for demanding environments, our segmented ball valves offer a diverse selection to ensure the correct application for your project.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Conclusion

Segmented ball valves provide numerous advantages over conventional ball valves, making them an ideal choice for process engineers in a wide range of industries. With enhanced control, superior sealing performance, erosion-resistant trim components, flexible shutoff options, and cost efficiency, segmented ball valves deliver exceptional results in demanding applications. Techno G’s high-performance segmented ball valves, featuring an inflatable seal and innovative designs, offer reliable and efficient solutions tailored to your specific needs. Embrace the benefits of segmented ball valves and optimize your processes for improved productivity and operational excellence.