Revolutionizing Cosmetic Powder Mixing with Techno-G's Ball Segment Valves

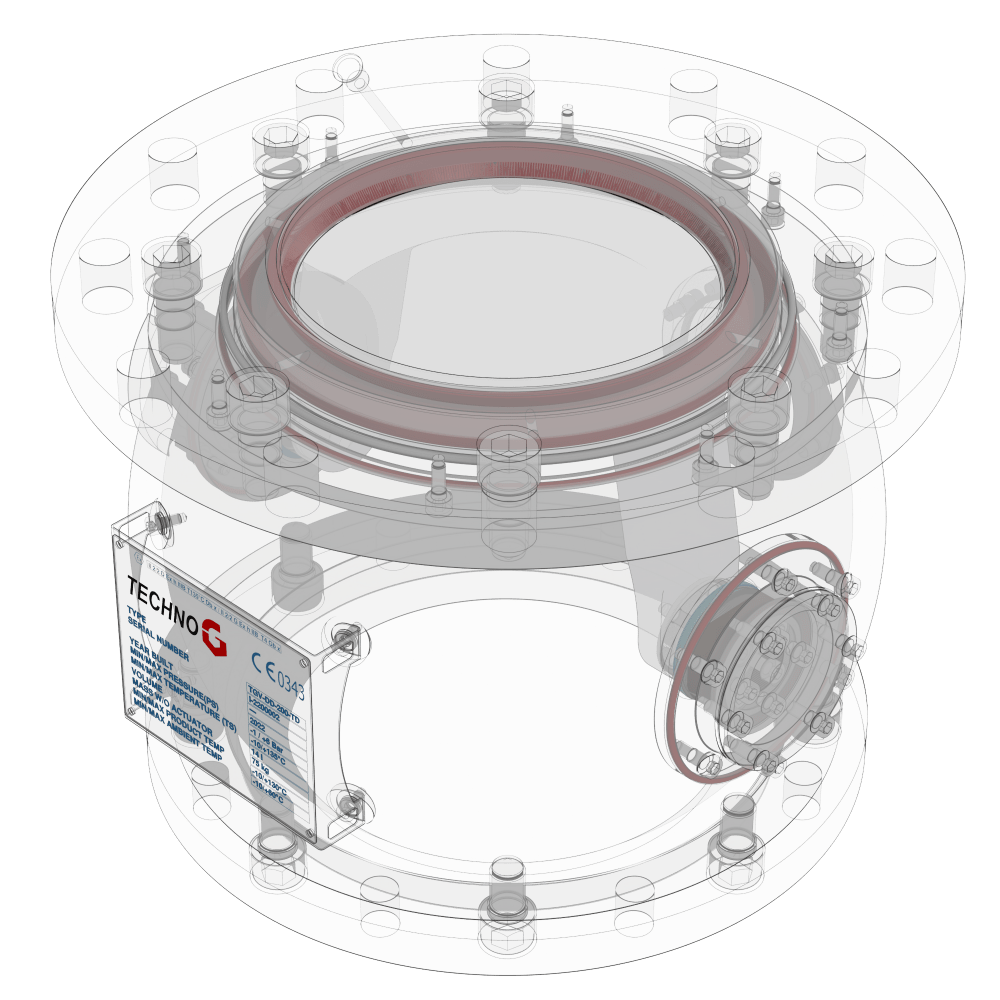

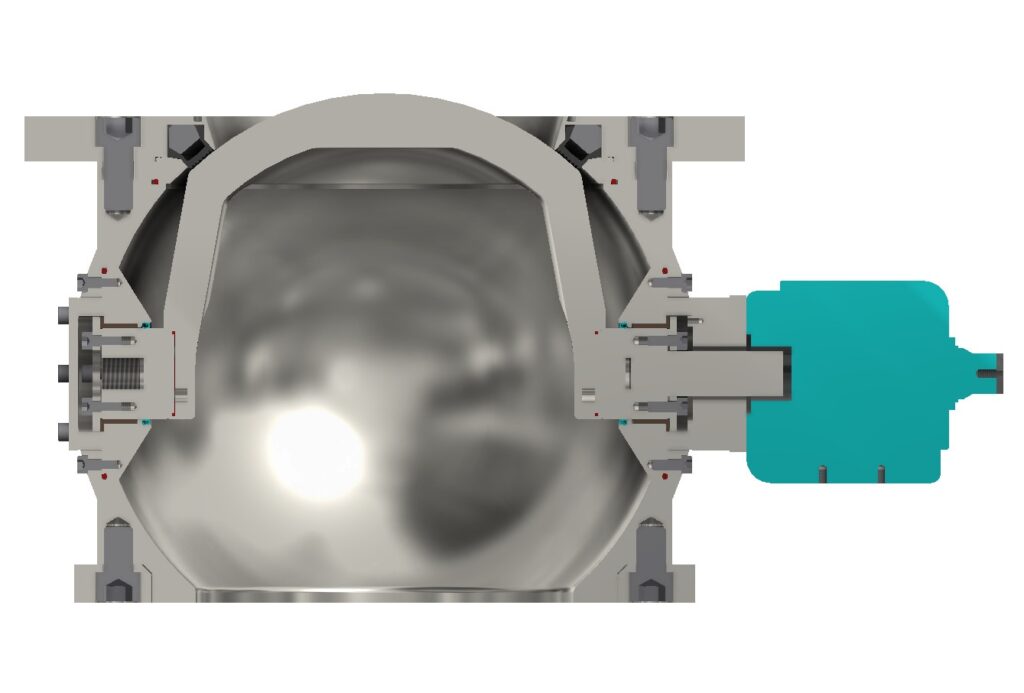

At Techno-G, we take pride in our innovative approach to mixing cosmetic powders, a process where precision and efficiency are paramount. Our advanced ball segment valve, a cornerstone of our expertise, is ingeniously designed to handle the delicate nature of cosmetic powders. This valve stands out with its unique inflatable seal, a critical component that ensures seamless operation. In action, the seal expands to fill the gap between the valve’s segment and the stationary scraper ring, ingeniously integrated into the housing. This meticulous design serves a dual purpose: it first sweeps away any solid particles that may have adhered to the segment, ensuring a clean passage. Secondly, it acts as a formidable barrier, preventing larger, potentially disruptive particles from reaching the seal’s vicinity. The result is an immaculate, uninterrupted flow of powder, crucial for maintaining the integrity and consistency of cosmetic products. Trust Techno-G to blend innovation with efficiency, bringing to the cosmetic industry a solution that is as elegant as the products it helps create.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

What's included

Characteristics of the Ball Segment Valve

Inflatable seal

Techno-G’s Ball Segment Valve features a unique inflatable seal, meticulously machined for precise tolerances, ensuring excellent vacuum and pressure tightness for diverse applications.

Modulair system

The Modulair system of Techno-G’s Ball Segment Valve offers customizable solutions, designed for vacuum drying and pressurized reactors, ensuring excellent vacuum and pressure tight seals for diverse applications.

Sealing materials

Our Ball Segment Valves utilize precision-machined seats and special bearings, ensuring an excellent vacuum and pressure-tight seal, tailored to individual processes and product requirements.

Vacuum and pressure

Techno-G’s Ball Segment Valve excels in vacuum and pressurized environments, thanks to precision machining and special bearings, ensuring an exceptional seal for diverse applications.

What's included

Characteristics of the Ball Segment Valve

Inflatable seal

Techno-G’s Ball Segment Valve features a unique inflatable seal, meticulously machined for precise tolerances, ensuring excellent vacuum and pressure tightness for diverse applications.

Modulair system

The Modulair system of Techno-G’s Ball Segment Valve offers customizable solutions, designed for vacuum drying and pressurized reactors, ensuring excellent vacuum and pressure tight seals for diverse applications.

Sealing materials

Our Ball Segment Valves utilize precision-machined seats and special bearings, ensuring an excellent vacuum and pressure-tight seal, tailored to individual processes and product requirements.

Vacuum and pressure

Techno-G’s Ball Segment Valve excels in vacuum and pressurized environments, thanks to precision machining and special bearings, ensuring an exceptional seal for diverse applications.

More about the industry

March 2025

Techno-G Introduces Advanced PTFE-Protected Ball Segment Valves for Chemical Processing

Techno-G2025-03-19T16:06:08+00:00Techno-G has announced an enhanced line of Ball Segment Valves featuring PTFE protection technology specifically engineered for solid handling in chemical and pharmaceutical applications.

The valves deliver exceptional non-stick properties with surface energy below 20 mN/m, temperature resistance up to 220°C, and complete chemical resistance across the pH 0-14 range. These...November 2024

Techno-G has a unique CIP cover for the entire Ball Segment Valve Range!

Techno-G2024-11-20T15:23:59+00:00Techno-G always opts for a "rotating CIP head" because it provides complete coverage within the entire housing and effectively reaches even the dead corners. Cleaning in Place (CIP) in the Pharmaceutical Industry: CIP is a process used to clean equipment and pipeline systems without disassembly. In the pharmaceutical industry, it is critical...

Hard Inchromising for Ball Segment Valve Heads

Techno-G2024-10-31T08:52:19+00:00In the (petro)chemical, pharmaceutical, and food industries, high-quality stainless steel alloys and nickel-based materials are frequently utilised. Although the choice of these materials may seem straightforward, they are unfortunately susceptible to corrosion and wear under certain conditions. When these materials are used in dynamic components, conventional techniques and materials often fall...

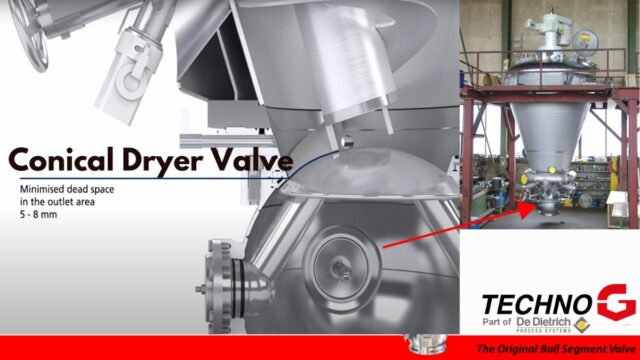

Paddle Dryer vs. Conical Dryer – A Technical Comparison

Techno-G2024-10-25T08:48:31+00:00In the chemical and pharmaceutical industries, selecting the right dryer is critical for ensuring product quality, stability, and manufacturing efficiency. Among the most commonly used types of dryers are Paddle Dryers and Conical Dryers. Both are designed to handle drying under challenging conditions such as high pressure and vacuum, and...

Techno-G Expands Material Options for Ball Segment Valves

Techno-G2024-10-18T09:49:31+00:00At Techno-G, our Ball Segment Valves are now available in a variety of advanced material configurations to meet the specific requirements of your applications. Whether you're dealing with highly corrosive environments or high temperatures, we have the right material solution to ensure optimal performance and longevity. Our Material Options: We understand...

October 2024

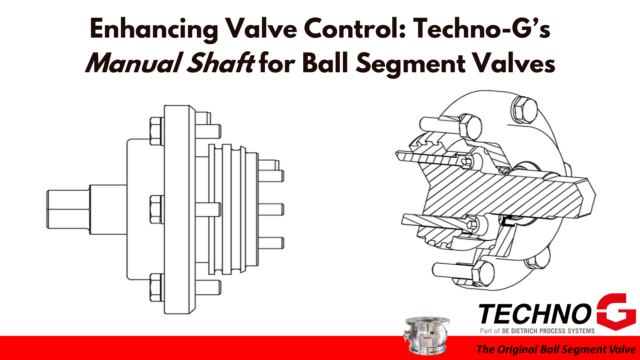

Enhancing Valve Control: Techno-G’s Manual Shaft for Ball Segment Valves

Techno-G2024-10-29T08:56:00+00:00At Techno-G, we manufacture high-performance ball segment valves and constantly aim to provide solutions that meet the unique needs of various industries. One of the essential components designed for enhanced valve control is our manual shaft, enabling precise and reliable manual operation of ball segment valves.

Table of Contents

Why the Manual...

September 2024

Nitrogen Purge Flange

Techno-G2024-09-20T07:46:34+00:00