Paddle Dryer vs. Conical Dryer – A Technical Comparison

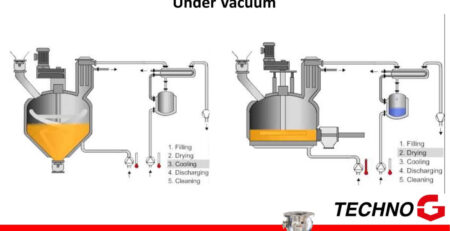

Techno-G2024-10-25T08:48:31+00:00In the chemical and pharmaceutical industries, selecting the right dryer is critical for ensuring product quality, stability, and manufacturing efficiency. Among the most commonly used types of dryers are Paddle Dryers and Conical Dryers. Both are designed to handle drying under challenging conditions such as high pressure and vacuum, and both can be equipped with Techno-G Ball Segment Valves—an essential component that ensures system reliability and efficiency. Here’s an overview of how these two types of dryers compare, and why ball segment valves play a crucial role in their operation.

Table of Contents

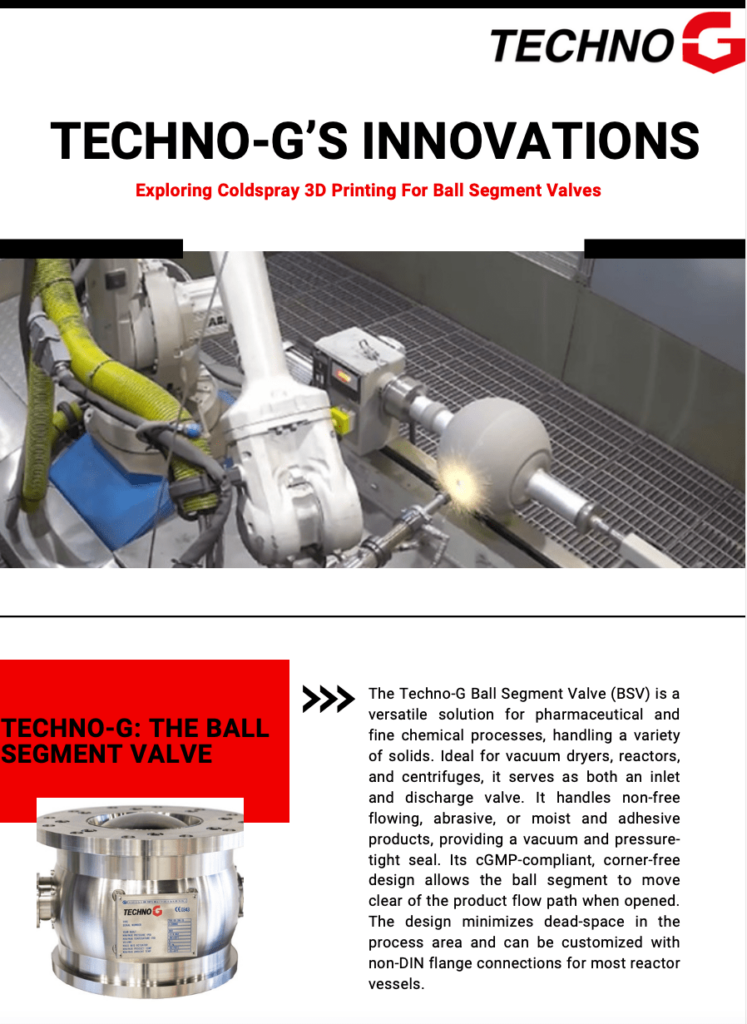

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

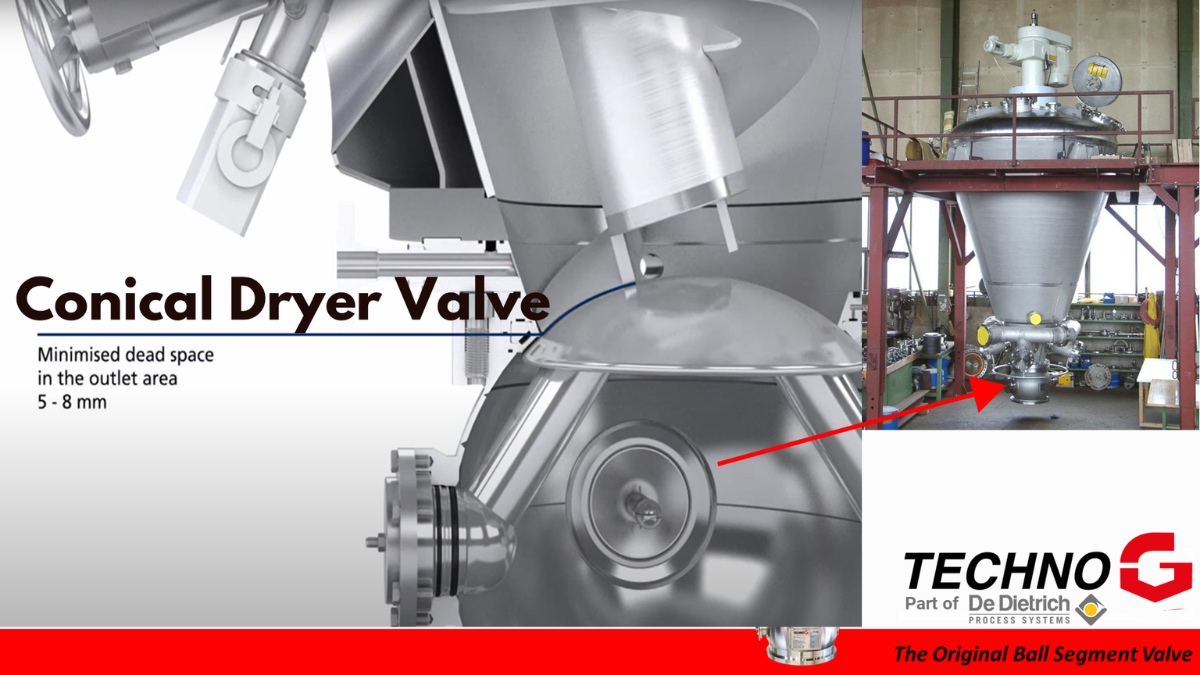

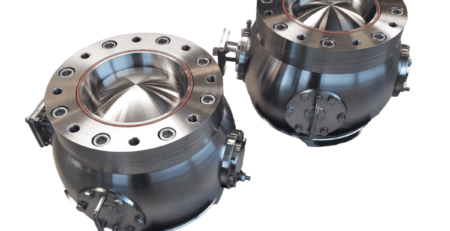

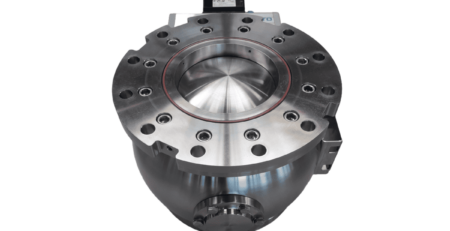

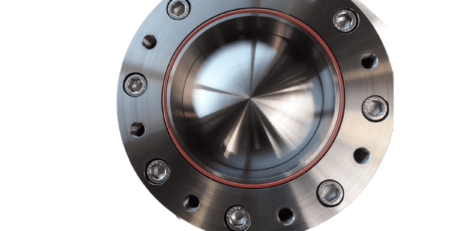

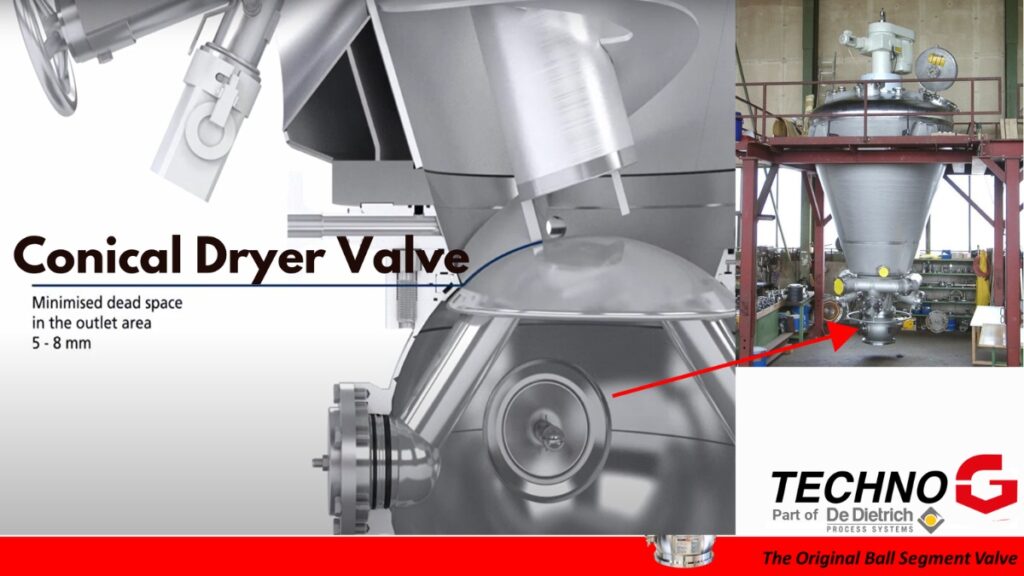

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Paddle Dryer

Design & Functionality:

A Paddle Dryer consists of a cylindrical vessel with a multi-paddle agitator mounted on a central rotating shaft. The paddles ensure continuous mixing and excellent contact between the product and the heated surfaces. This promotes efficient heat transfer, allowing for quicker drying times. The heating fluid typically circulates not only through the vessel wall but also through the agitator itself, further enhancing the drying process.

Applications:

Paddle Dryers are especially suitable for drying slurries, pastes, or materials with higher moisture content. Their ability to handle high-shear materials makes them ideal for products requiring intensive mixing.

Advantages:

- High heat transfer efficiency.

- Suitable for continuous operation.

- Handles products that require faster drying.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Conical Dryer

Design & Functionality:

In contrast, the Conical Dryer features a cone-shaped vessel mounted horizontally, which rotates to provide consistent mixing. Its simple design, often referred to as a Conical Tumble Dryer, enables it to offer cost-effective drying solutions. The rotation of the vessel ensures that the product makes regular contact with the heated walls, making the dryer ideal for gentle drying processes.

Applications:

Conical Dryers are typically used for drying heat-sensitive materials such as powders and granules. Their ability to operate at low temperatures under vacuum makes them a preferred choice for pharmaceutical applications where product quality and purity are paramount.

Advantages:

- Gentle drying process.

- Cost-effective and efficient for low-temperature applications.

- Reduces thermal stress on heat-sensitive products.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

The Role of Techno-G Ball Segment Valves

In both Paddle and Conical Dryers, Techno-G’s Ball Segment Valves are integral to maintaining system integrity, especially under vacuum and pressure. These dryers typically operate under extreme conditions—high temperatures and vacuum environments—to accelerate the drying process without compromising product quality. Here’s why ball segment valves are critical for dryer operation:

- Sealing Under Vacuum and Pressure:

Techno-G Ball Segment Valves are designed to remain tightly sealed during vacuum drying, preventing air ingress that could compromise drying efficiency. They also maintain the seal when the dryer is under high pressure, such as when inert gases are introduced during certain phases of the drying process. - Preventing Product Contamination:

Maintaining a perfect seal with Techno-G valves ensures that the product inside the dryer is protected from external contaminants. This is particularly important in pharmaceutical and chemical applications, where even the smallest impurities can affect product quality. - Durability Under Extreme Conditions:

The ball segment valves are manufactured from corrosion-resistant materials such as Hastelloy, Inconel, and Stainless Steel to withstand the harsh chemical and thermal environments typical in dryer operations. This durability ensures long-term, reliable performance even under continuous high-temperature and vacuum conditions.

Conclusion

The choice between a Paddle Dryer and a Conical Dryer depends on the specific requirements of the product and process. While Paddle Dryers excel in processing high-moisture, high-shear materials, Conical Dryers are ideal for heat-sensitive products. However, in both types of dryers, the use of Techno-G Ball Segment Valves is essential to maintaining system integrity, ensuring product quality, and delivering efficient, reliable drying performance. By selecting Techno-G valves, manufacturers can be confident in the longevity and reliability of their drying systems, even in the most demanding chemical and pharmaceutical applications.