Segment valve features and common applications

tim2024-02-05T12:12:16+00:00Segment valves, a cornerstone of industrial technology, are embraced for their versatility and efficacy in handling a variety of materials, especially fine solid materials. Let’s delve into the distinct attributes of segment valves and their wide range of applications.

Table of Contents

Understanding segment valves

A segment valve, often referred to as a segmented ball valve, is a specialized type of control valve. It incorporates a ball segment that is cut away to allow the passage of material. This unique design offers excellent control of solids, making it an ideal choice for various industrial applications. The options available for these valves are diverse, catering to a wide range of operational requirements.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Key features

- Advanced material selections: Segment valves are constructed from a variety of materials, tailored to suit specific applications. The material specifications of these valves make them suitable for handling abrasive, and corrosive materials.

- Efficient control valve design: These valves are designed for efficient torque transmission and feature low-friction operation, ensuring precise control in solid handling. They offer excellent tightness and sealing capabilities by regulating pressure levels.

- Versatility in applications: Segment valves are adept at handling solids and especially cohesive materials. Their flexible design allows them to be used in various industries.

Range of applications

Industrial sectors

Pharmaceuticals and chemicals: In pharmaceutical and chemical industries, segment valves are used for the precise control of powders and granular materials, where contamination and accuracy are critical concerns.

Food and cosmetics: The food and cosmetics industries benefit from the hygienic and accurate control capabilities of these valves, especially in processes involving powders.

Metals and minerals: Segment valves are particularly advantageous in metals and mineral processing, where handling large volumes of solid materials is a routine challenge.

Specific applications

- Abrasive solids applications: For aggressive solid materials, segment valves provide durability and efficient control, minimizing wear and tear.

- Solid processes: In solid process applications, the precise control offered by these valves is essential for maintaining system efficiency and safety.

- Fine chemical handling and control: For operations requiring accurate control of chemicals, these types of valves offer solutions that balance flow dynamics and pressure control.

Download our free whitepaper

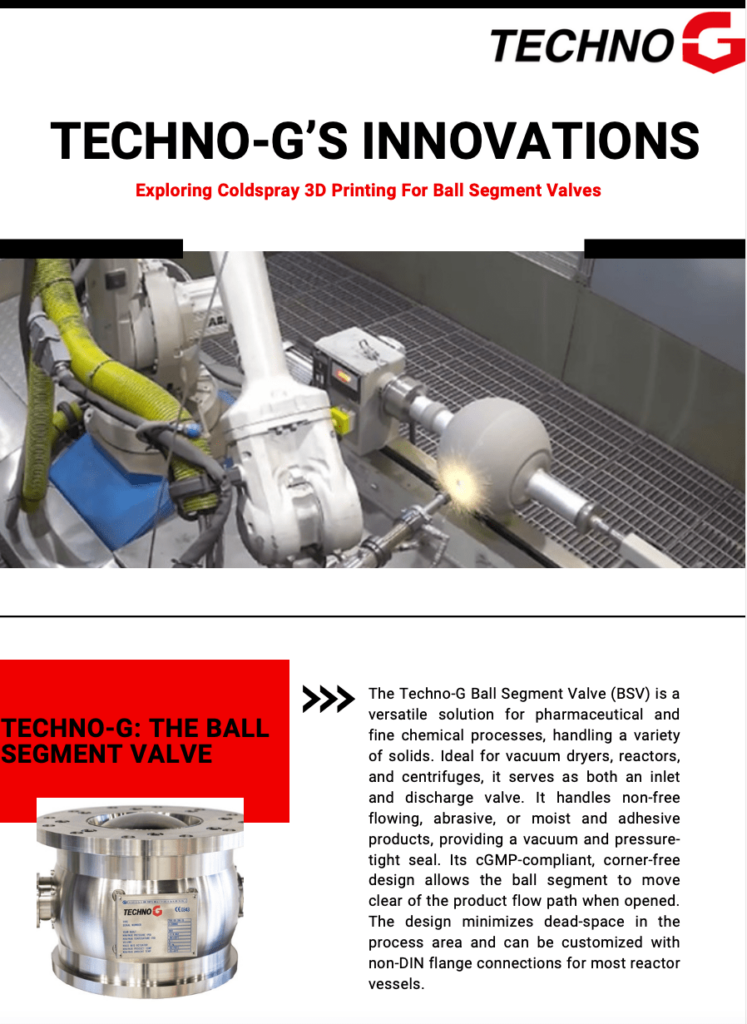

"Exploring Coldspray 3D Printing For Ball Segment Valves"

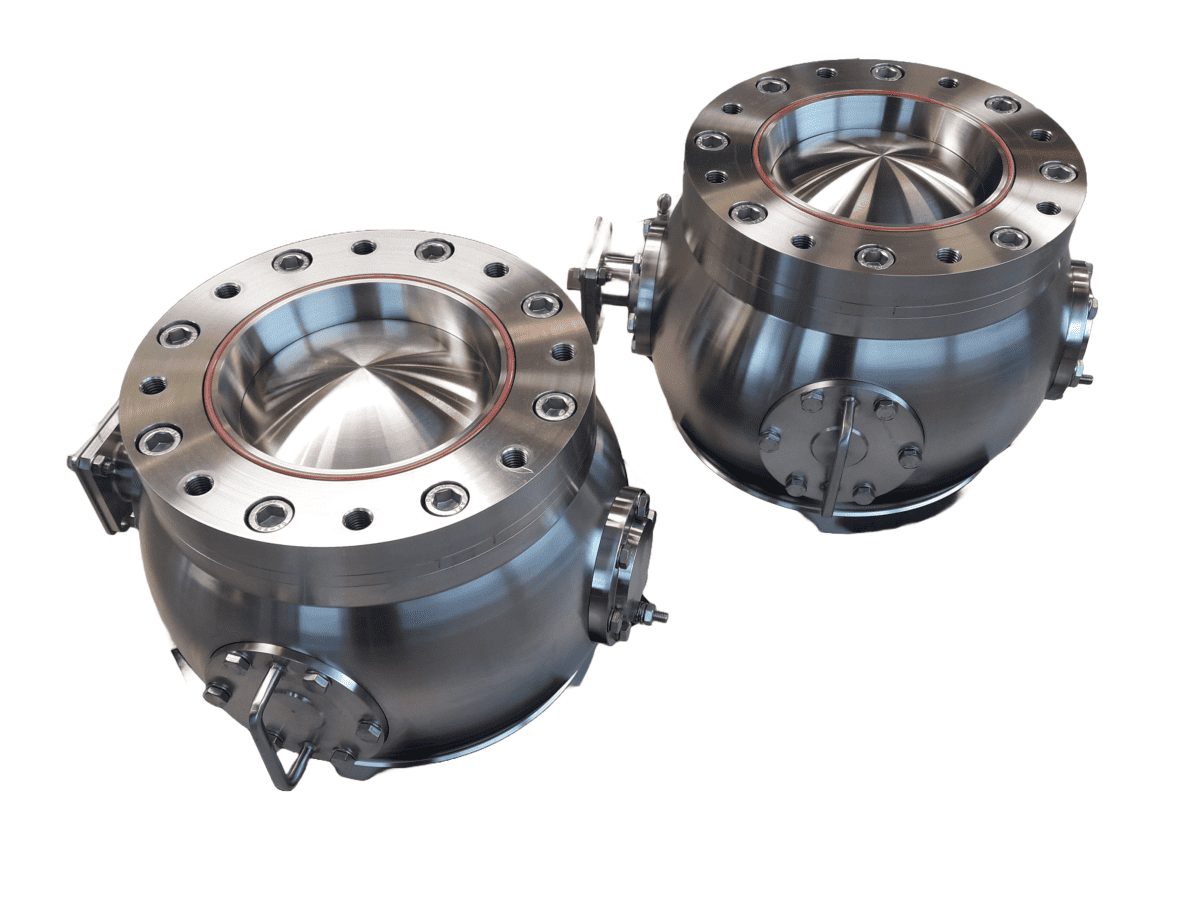

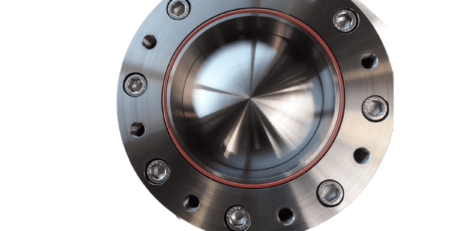

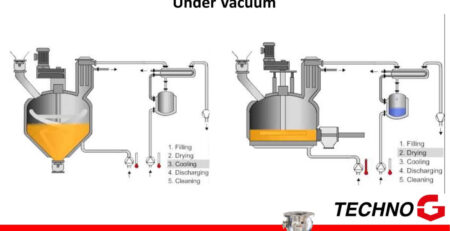

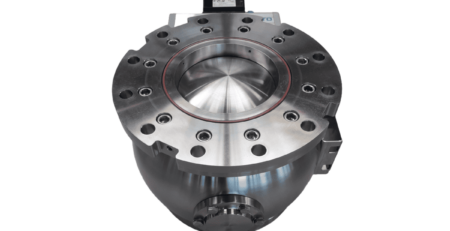

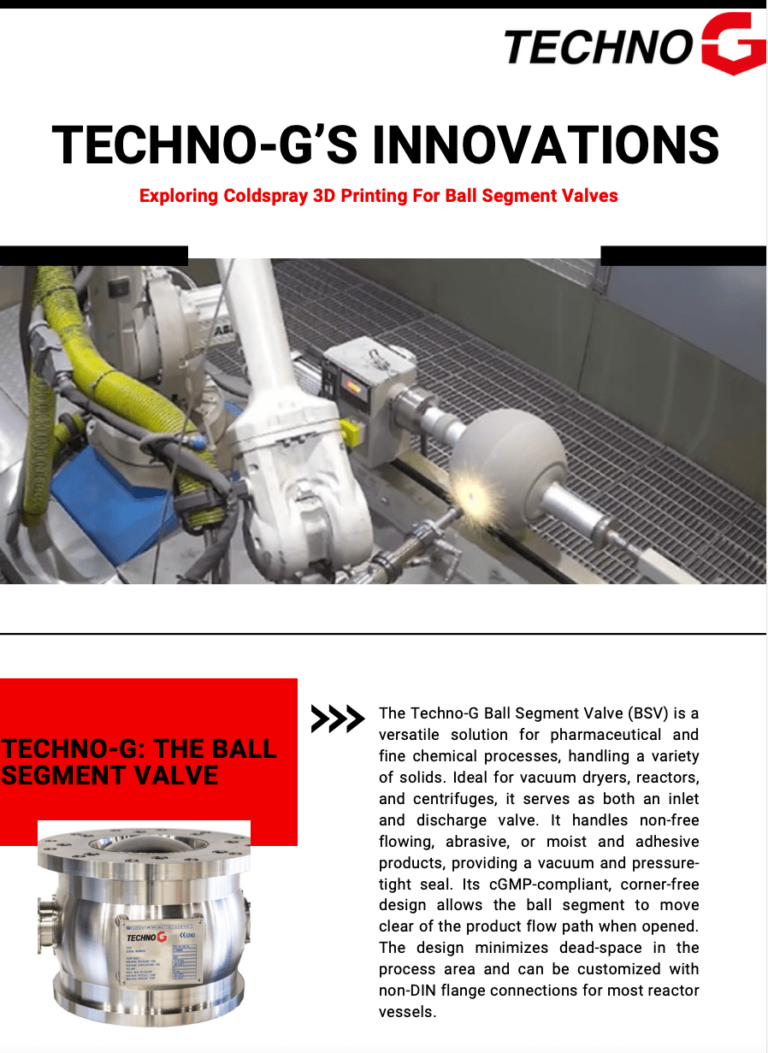

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Technological innovations

At Techno-G, innovation is at the heart of our product design. Our 3D cold spray printed titanium ball segment valves represent a leap in manufacturing technology, offering enhanced strength and reduced weight. Additionally, our focus on high-level quality control ensures that every valve we produce meets the strictest industry standards.

Advanced features of our ball segment valves

- Customization and adaptability: Our unique ball segment valves are not just about handling tough materials; they are about doing so with precision and adaptability. We understand that each industry has unique needs, and our valves reflect that. From the food industry to handling fine chemicals, our valves offer special executions for different applications.

- Enhanced sealing performance: One of the standout features of our valves is the inflatable seal. This high-quality inflatable seal ensures long-term, reliable sealing, making it ideal for handling materials where leakage is a major concern. The seal’s adjustable nature allows for a perfect fit, ensuring excellent tightness even under varying operational conditions.

- Diverse actuation options: Actuators play an essential role in the functionality of segment valves. That’s why we offer a variety of actuator options, including electric actuators and manual options. This flexibility allows our clients to choose the best fit for their specific control requirements and operational environments.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Techno-G’s standards

At Techno-G, quality is not just a buzzword; it’s the foundation of everything we do. Our valves undergo rigorous quality control and certifications, ensuring that they meet the highest standards of reliability and performance.

Applications in detail

- Handling abrasive and corrosive materials

Ball segment valves are particularly effective in handling abrasive and corrosive materials. Their robust design and material options, like stainless steel and other material alternatives, ensure longevity and reliability in challenging environments. - Optimizing flow and pressure

In industries where flow and pressure control are critical, such as in chemical processes, ball segment valves offer precise control. Their design minimizes drops in pressure and ensures a smooth flow path, optimizing system efficiency. - (Fine) solid handling

The handling of (fine) solid materials, especially in mineral processing and metal industries, requires valves that can manage batches efficiently. Our ball segment valves, with their wide range of sizes and adjustable sealing, are perfectly suited for these applications.

More than a component

Segment valves are more than just a component; they are an essential part of the industrial process. With a full bore design, quality manufacturing, and commitment to customer needs, our ball segment valves are setting new standards in the valve industry. To learn more about how our valves can enhance your operations, explore our website or contact us directly.

Stay ahead in your industry with Techno-G’s segment valves – where innovation meets precision and reliability.