Why is a chemicals valve crucial in the processing and handling of substances?

tim2024-02-05T11:18:39+00:00In the world of fine chemical processing, the huge role of a chemicals valve cannot be overstated. At Techno-G, particularly our high-quality ball segment valves, plays an important role in this sector. But why is such a valve so indispensable? Let’s dive deeper into chemical processing and the unique benefits these valves offer.

Table of Contents

The heart of chemical efficiency

Fine chemical substances require precise handling, where every drop or granule matters. This is where valves, particularly those designed for fine chemicals, come into play. They are not just a component; they are the heart of chemical applications, dictating the efficiency, safety, and quality of the entire process.

Ensuring safety and precision

Safety in the chemical industry is paramount. A reliable valve ensures a safe and controlled environment. This is crucial when dealing with corrosive or hazardous solid substances. The design of ball segment valves minimizes the risk of leaks and accidental exposure, safeguarding both the product and the personnel.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

The technological edge of ball segment valves

Our ball segment valves, especially designed for fine solid materials, come equipped with an efficient inflatable seal. This feature allows for optimal pressure management, ensuring that even the finest of materials are handled with the utmost precision.

Tailored for specific needs

Each application has its exact application requirements. The customizable options of Techno-G’s valves, ranging from material specifications to control box designs, ensure that every need is met, whether it’s for pharmaceuticals, cosmetics, or the food industry.

Efficiency and cost-effectiveness: The economic angle

Reducing operational costs

In any industry, cost-effectiveness is a key consideration. Valves for chemicals, by optimizing operational efficiency and reducing the need for maintenance, are key components in lowering energy costs and overall operating expenses.

Longevity and durability

The durability of valves further drives down long-term costs. By investing in high-quality, industries can avoid frequent replacements and maintenance, leading to significant cost savings.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Download our free whitepaper

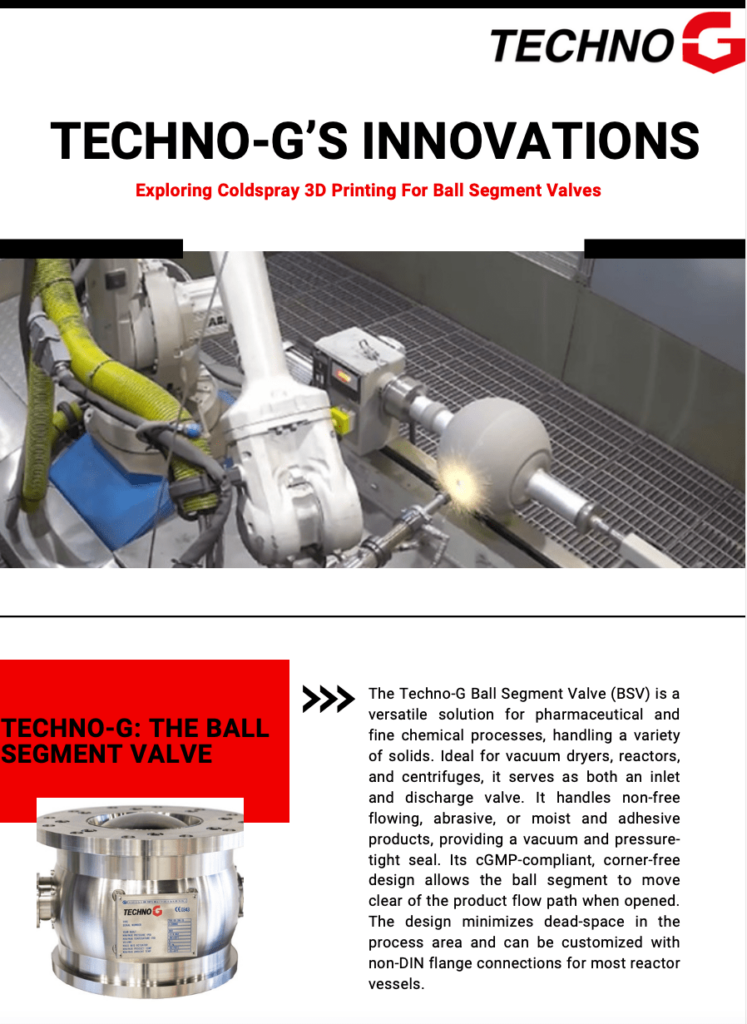

"Exploring Coldspray 3D Printing For Ball Segment Valves"

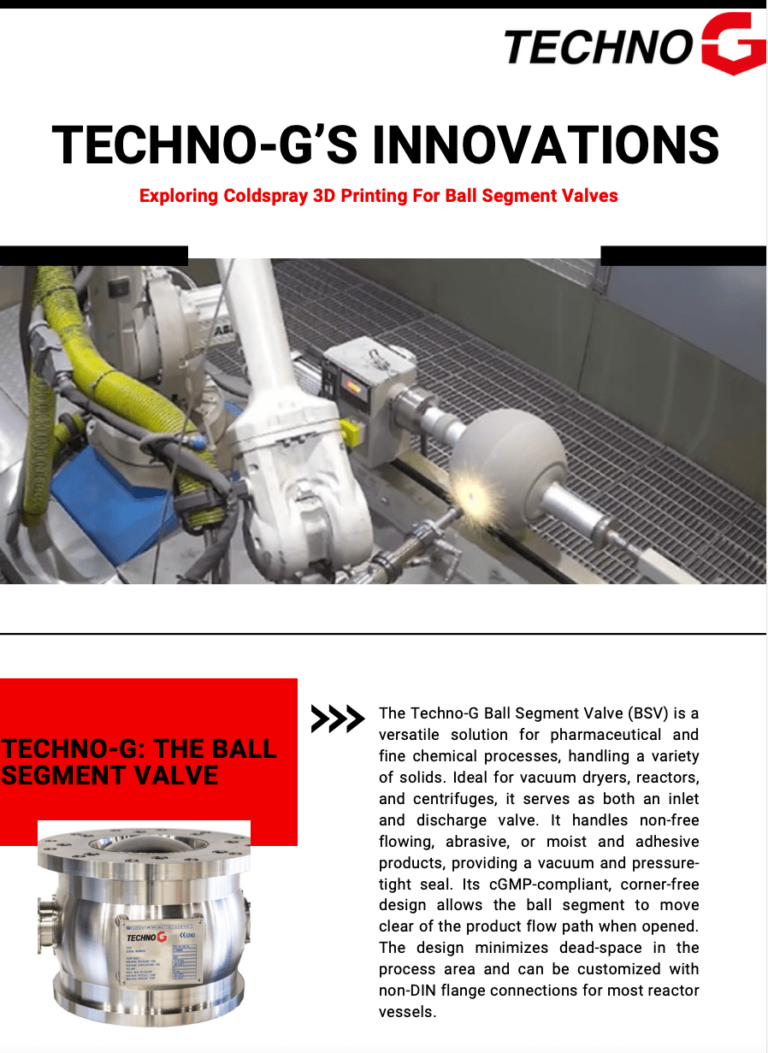

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Exploring the versatility valves in diverse industries

From here, we delve deeper into the versatility of ball segment valves, exploring their potential across various industries. Our valve, known for its precision and reliability, caters to a broad spectrum of applications, demonstrating their indispensability.

Wide range of applications

1. Pharmaceuticals

In the pharmaceutical industry, precision is non-negotiable. At Techno-G, we ensure accurate dosing and handling of solid pharmaceutical ingredients, adhering to stringent industry standards.

2. Cosmetics

The cosmetics industry demands a high level of precision and quality control. Valves guarantee the delicate handling of cosmetic ingredients, ensuring the consistency and quality of the final products.

3. Food processing

Food safety and quality are paramount in the food industry. We ensure that food ingredients are processed in a hygienic and efficient manner, contributing to the production of safe and high-quality food products.

4. Fine chemicals and API

In the fine chemicals and API sector, the valves play an important role in handling active pharmaceutical ingredients and other fine chemicals with the required precision and care.

Specialized solutions from us!

Customizable options for unique needs

Every industry has its unique requirements. At Techno-G, we offer special executions of valves, tailoring them to meet specific industry needs, be it in materials, size, or functionality.

Advanced material and dependability

The use of advanced materials like Hastelloy or the 3D-printed titanium and reliable creations such as the inflatable seal enhances the performance and reliability of our valves, making them suitable for even the most demanding applications.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Future-proofing with advanced technology

In the ever-evolving world of industrial processing, staying ahead with technology is key. Our ball segment valves, with their advanced actuator systems and quality control certifications, represent the future of valve technology in chemical processing. By focusing on energy-efficient designs, we contribute to sustainable operations, reducing the overall environmental footprint of industrial processes.

The essential role

The significance of chemicals valves in various industries cannot be overstated. They are integral to the efficient, safe, and cost-effective processing of fine chemical substances. We stand at the forefront of this technology, offering valves that are not just products but essential components in the broader narrative of industrial excellence.

For more insights into how our valves can transform your processes, reach out to us directly through our contact page. Stay informed about the latest developments in valve technology by visiting our news section.