How paddle dryer valves Improve efficiency in handling solids

tim2023-12-08T15:08:41+00:00Paddle dryers, for some of you indispensable, are essential for drying powders, pastes, and slurries efficiently. However, the efficiency of a paddle dryer is heavily influenced by its components, particularly the paddle dryer valve. In this article, we’ll explore how our Ball Segment Valves enhance the performance of paddle dryers in handling solids and fine chemicals.

Understanding paddle dryers and their function

Before delving into the specifics of valves, it’s crucial to understand the basic operation of paddle dryers. Paddle dryers are designed for drying, heating, and cooling of slurries, pastes and loose powders. They work under atmospheric or low-pressure conditions, ensuring gentle yet effective drying. Key components, like the paddle design and the dryer body, play a significant role in the process.

The significance of segment valves for drying processes

Paddle dryer valves, such as our innovative Ball Segment Valves, are essential in controlling the flow of materials into and out of the dryer. These valves ensure a smooth transition of materials, maintaining product quality and consistency. They are particularly crucial for handling delicate products, regulating pressure, and ensuring minimal damage during the drying process.

The Ball Segment Valves are designed with an advanced inflatable seal, ensuring optimal pressure management and zero leakage. This feature is particularly beneficial for handling heat-sensitive and fine chemical products, as it maintains the integrity of the product throughout the drying process.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Key benefits of using high-quality valves

- Enhanced efficiency: The right valve can significantly improve the drying rates, leading to more efficient batch drying. This is particularly important in industries like pharmaceuticals and chemicals, where precise moisture content is crucial.

- Improved product quality: High-quality valves, such as the 3D printed titanium construction, offer superior control over the drying process, ensuring consistent product quality.

- Versatility: These valves are suitable for a wide range of materials, making them ideal for various applications in different industries, such as metals, minerals, and chemicals.

- Durability and reliability: Made from robust materials like stainless steel, valves are built to last, offering reliable performance under various operating conditions.

- Customization: At Techno-G, we provide bespoke system solutions to meet specific customer requirements, ensuring that the valve perfectly fits your application’s needs.

Application in various industries

Paddle dryer/ Ball segment valves find extensive use across various industries. For instance, in the pharmaceutical industry, these valves handle delicate products and ensure compliance with strict industry standards. Similarly, in the chemical industry, they play a role in managing hazardous and sensitive chemical compounds and solids.

Technical aspects of paddle dryer valves

Paddle dryer valves, such as the Ball Segment Valve, are engineered with precision to handle a variety of materials under different conditions. These valves are integral to ensuring the effective and efficient operation of paddle dryers.

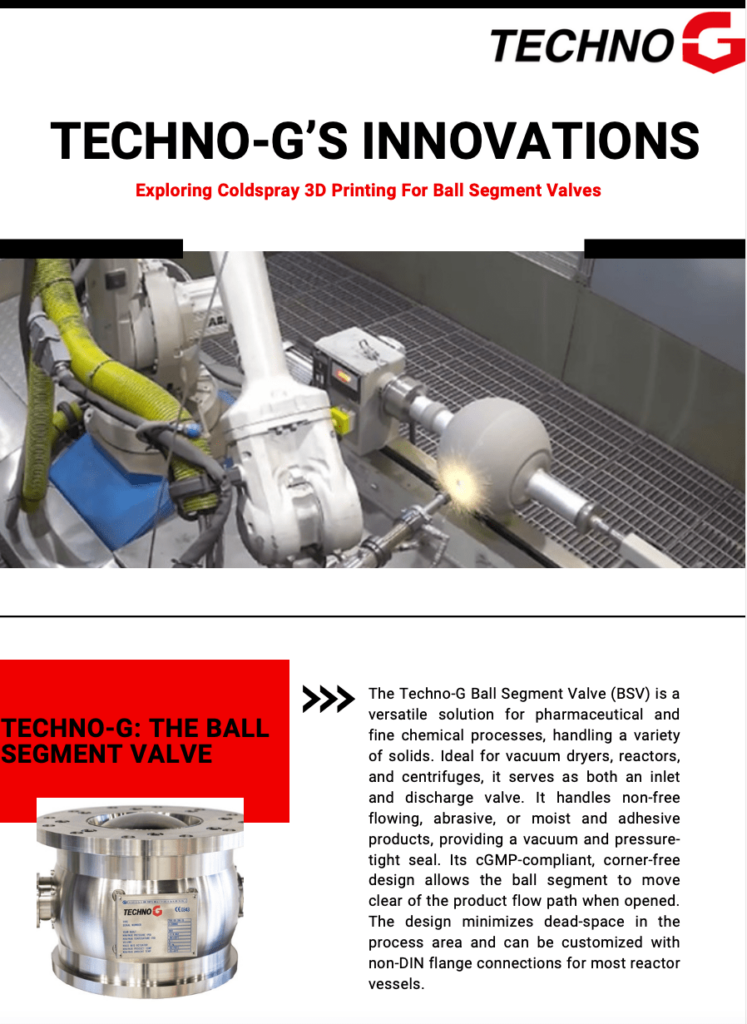

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

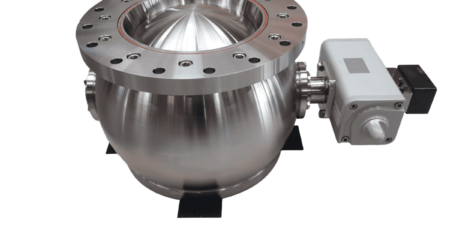

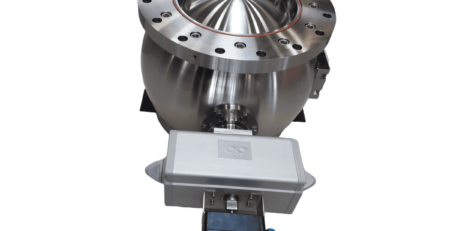

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

Unique design features

The design of paddle dryer valves often includes features that cater to specific industry needs. For instance, Ball Segment Valve enhances a compact and robust design, suitable for handling both dry and semi-wet solid materials. This adaptability makes the valves highly versatile for different applications.

Automation and control

Modern paddle dryer valves are often part of automation systems, allowing for precise control over the drying process. This automation is crucial for maintaining consistent quality, especially in batch-wise operations.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Real-world applications in industries

- Pharmaceutical

In the pharmaceutical industry, paddle dryer valves play a factor in maintaining the integrity of sensitive products. They ensure that the drying process does not adversely affect the chemical properties of pharmaceuticals, a key consideration given the quality control.

- Food

For the food industry, these valves ensure that the color and texture of food products are preserved during drying. This is essential for maintaining the appeal and nutritional value of food products.

- (Fine) chemicals

The chemical and fine chemicals industry benefit from the use of paddle dryer valves in handling heat-sensitive and potentially hazardous materials. The valves’ ability to operate under vacuum conditions and manage different types of slurries and pastes is particularly valuable.

- Other industries

Valves for paddle dryers also find applications in cosmetics, minerals, metals, and various other industries. Each industry benefits from the specialized features of these valves, tailored to their unique requirements.

Innovative solution for you

Valves for paddle dryers, such as the innovative solutions offered by us, are key to enhancing the efficiency and effectiveness of drying processes across various industries. Their advanced design, coupled with the ability to handle a diverse range of materials, makes them an indispensable component in modern industrial applications.

For more insights and updates on our products and their applications, visit our news page or reach out to us through our contact page.