How pharmaceutical solids valves ensure safe and secure handling

tim2023-09-12T11:28:56+00:00Hello process engineers and anyone interested in the marvels of modern industrial technology! Today, we’re diving into a critical piece of equipment in many industries – the pharmaceutical solids valve. Specifically, we’re going to focus on how this nifty device ensures the safe and secure handling of pharmaceutical solids. Let’s get started!

Aseptic applications and septic design

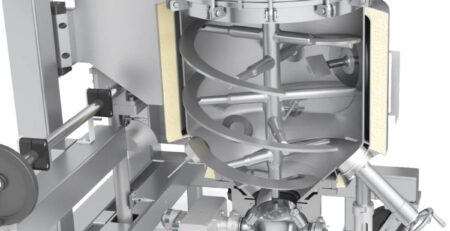

In the pharmaceutical industry, rigorous control processes are a fundamental requirement. Every detail, from aseptic applications to the choice of materials for the valves, plays a critical role in ensuring operational success. At Techno-G, we offer an ideal solution: our segmented ball valve with an inflatable seal, designed explicitly for handling solid materials, including bulk solids and other solid products.

Constructed from high-grade stainless steel, our valve exhibits exceptional resistance to corrosion, offering continuous protection, thus maintaining the integrity of your solid products. The flow-efficient valve disc ensures reliable shut-off operations, vital in handling and controlling the flow of bulk solids.

The outstanding feature

One of the most outstanding features of our segmented ball valve is the inflatable seal. This seal guarantees superior tightness, making it an excellent choice for aseptic processes where the risk of contamination must be minimized.

In an industry where the safe and efficient handling of solid material is paramount, our stainless steel segmented ball valve with an inflatable seal represents a perfect blend of innovative design, robust construction, and operational efficiency, catering to the unique demands of the pharmaceutical sector.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Different types of valves

In the world of pharmaceutical applications, a vast array of valve types is available, each serving its purpose. Centric butterfly valves, with their simple designs and lightweight design, are commonly used in hygienic applications and the food industry. Similarly, the eccentric butterfly valve offers an optional spring for safe regulation during the closing process. They move from an open to CLOSED position smoothly, ensuring minimum wear and tear.

For more difficult applications, such as dealing with dry materials or fibrous pharmaceutical products, knife gate valves and pinch valves offer reliable performance. Techno G also boasts an extensive product range of control valves, including Control Globe Valves and Ceramic Ball Valves, which are specifically designed for control applications.

The valve body, bulk material, and flow rate: Ensuring efficient performance

In pharmaceutical processing, the interaction between the valve body, bulk material, and flow rate is critical for efficiency. At Techno-G, we understand this delicate balance and carefully design our valves accordingly.

Our valve bodies, usually made of robust metals like stainless steel, resist corrosion and contamination. Their shape and polished surfaces are designed to minimize material accumulation and promote smooth flow. We accommodate a wide variety of materials, from solids to liquids, thanks to our understanding of different material properties.

We also ensure optimal flow rates using pneumatic control systems. Our valves have different pressure ratings and include pressure relief designs for added safety, preventing blockages and waste.

With multiple connection options and a keen eye on material choice and design, Techno-G guarantees safe, efficient handling of pharmaceutical solids, reflecting our commitment to superior performance and reliability.

Inflatable Seal: A Techno G Innovation

Perhaps the most remarkable aspect of Techno G’s valve is the inflatable seal. This feature provides a tight seal that allows for the safe operation and handling of dry solids, even fibrous products. Its effective protection against leakage, along with its ability to withstand extreme temperatures, makes it an excellent choice for demanding industries, not just pharmaceuticals but also food, beverage, and chemical industries.

Additional corrosion protection and material alternatives

At Techno-G, our valves stand out with their aseptic design and innovative inflatable seal, further enhanced by additional corrosion protection. With a variety of material alternatives available, our valves boast excellent service life and lower maintenance costs. We adhere to the strictest regulations and quality standards, providing valves that not only meet but also exceed regional standards.

Modular actuator concept

Our unique modular actuator concept significantly contributes to the performance of our valves. Whether you require a pneumatic actuator for a centric butterfly valve or an electric actuator for a ceramic ball valve, our wide range of options ensures you find the perfect fit for your specific application needs.

Prioritized accessibility and maintenance

Despite the complexity of our valves, we’ve prioritized accessibility for maintenance. This feature guarantees their longevity and consistent performance over time, contributing to continuous operation—a critical factor in industries like pharmaceuticals, food, and beverages where reliability is paramount. At Techno-G, we’re committed to maintaining your operational edge through our advanced, high-quality valves.

Techno G’s broad application: The power of versatility

Our innovative products are suitable not just for pharmaceuticals but also have a wide range of applications across various industries. From chemical plants, hydropower plants, water distribution plants, and even in tough applications like the petrochemical industry, Our Techno-G valves offer peak performance, thanks to their innovative designs and high-quality materials.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

The future of valve technology

The world of industrial valves is ever-evolving, with new technologies and designs continually emerging. Techno G is at the forefront of this evolution, always seeking to offer its customers the latest and greatest in valve technology. Whether it’s exploring the use of new materials, refining the design of existing products, or innovating entirely new solutions, Techno G is committed to pushing the boundaries of what’s possible in valve technology.

Conclusion

The safe and secure handling of pharmaceutical solids isn’t as simple as it might seem, but with the right equipment – like Techno G’s pharmaceutical solids valves with the innovative inflatable seal – it becomes much more manageable. Our valves offer unmatched quality, effective protection, and exceptional versatility, making them an essential piece of technology in many industries. Whether it’s pharmaceuticals, food, beverage, or chemicals, Techno G’s valves are up to the task!

So next time you’re dealing with pharmaceutical solids or other industrial bulk materials, remember the unsung hero of the process – the pharmaceutical solids valve. The silent workhorse, ensuring the safe, efficient, and continuous operation of a multitude of industries.