Valve for solids: The key to effective and efficient bulk handling

tim2023-09-12T11:26:49+00:00As any process engineer working in pharmaceuticals, chemicals, fine chemicals, API, food, cosmetics, minerals, metals, and more will tell you, handling bulk materials, especially solid particles, can be a tricky business. Ensuring smooth, efficient flow control is a complex task requiring not just any valve, but specifically a valve for solids. Welcome to our world where this crucial component turns into a game-changer, thanks to the high-performance segmented ball valve, complete with an inflatable seal.

The critical role of valves for solids

Rising above the common valve types: The segmented ball valve

How does the segmented ball valve work?

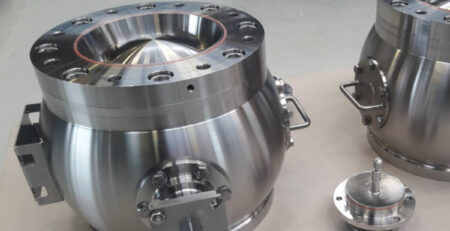

The segmented ball valve is a core component in solid and bulk handling systems, playing a critical role in ensuring both effectiveness and efficiency. This unique valve operates by using a ball or a segment with a hole, which can rotate within the valve body to control the flow of materials.

When the hole aligns with the pipeline, the valve is in the open position, allowing materials to flow freely through it. When the solid part of the ball or segment is rotated into the pipeline, the valve is considered closed, halting the flow of materials.

What makes the segmented ball valve particularly useful in bulk handling is its ability to provide a tight seal when closed, even under high-pressure conditions. This is crucial in preventing leakage and ensuring the secure transport of materials. Its design also facilitates minimal friction during operation, contributing to reduced wear and a longer lifespan.

No space too tight with the inflatable seal

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

The advantage of an ball segment valve in solids- and bulk handling

The ball segment valve offers several advantages when it comes to handling solids and bulk materials, making it an ideal choice for a myriad of industries and applications. Here are some of the primary benefits:

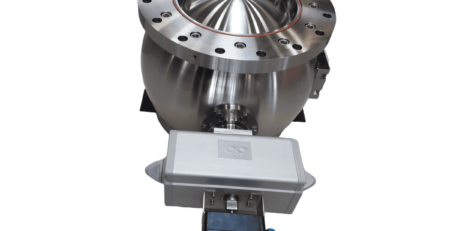

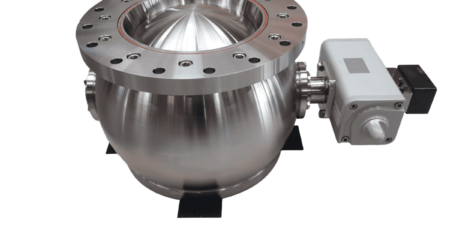

- Superior sealing: Thanks to its inflatable seal, the ball segment valve provides excellent sealing performance. This ensures that there are no potential leak paths, making the valve safe and reliable even in the presence of aggressive materials.

- Robust design: The ball segment valve’s design and construction materials, including carbon steel and stainless steel, allow it to withstand harsh operating conditions and ensure long service life.

- Versatility: With its unique design, the ball segment valve can handle a wide range of materials, from powders to granules and more. It’s suitable for various applications, including vacuum drying, pressure reactors, and others.

- Easy maintenance: The design of the ball segment valve allows for easy access for maintenance, further increasing its lifespan and reducing operational costs.

- Efficient flow control: The ball segment valve offers superior flow control capabilities. It can effectively regulate the flow of materials, ensuring smooth and efficient operation in any solid or bulk handling process.

By incorporating a ball segment valve into your solid or bulk handling processes, you stand to benefit from these and many more advantages, resulting in improved operational efficiency and performance.