Vacuum ball valve and its role in boosting process efficiency

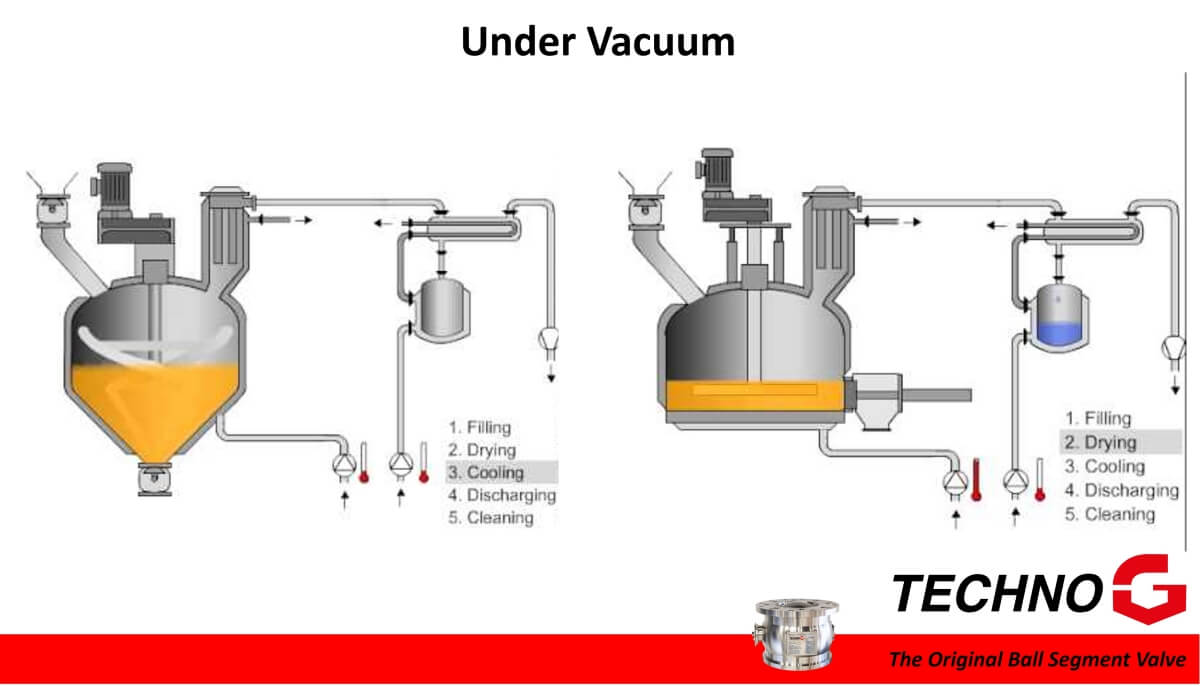

tim2023-10-18T10:21:04+00:00When it comes to vacuum-based processes, efficiency is paramount. Process engineers understand the importance of reliable and precise equipment that can withstand demanding conditions. One such crucial component is the ball valve vacuum, which plays an important role in ensuring smooth operations.

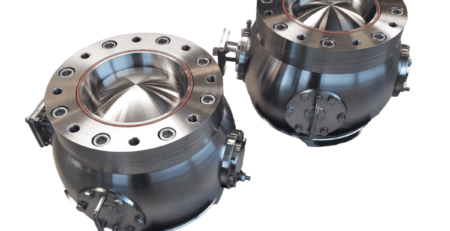

In this article, we will delve into the world of ball valve vacuum and explore how it contributes to the efficient operation of vacuum-based processes. We’ll also highlight the exceptional quality of Techno G’s segmented ball valve, specifically designed for solids handling, and showcase its innovative inflatable seal, which ensures a tight and leak-free closure for enhanced safety and efficiency.

Understanding a ball valve vacuum

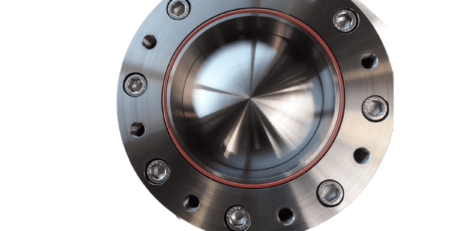

A ball valve vacuum is a type of valve that utilises a ball-shaped disc to control the flow of fluids or gases in a vacuum system. It consists of a hollow ball with a hole in the centre, which acts as the flow path. The ball rotates within a housing, allowing for precise regulation of the fluid or gas flow. Ball valves are known for their bi-directional leak-tight sealing, ensuring that no medium escapes or enters the system when the valve is closed.

2-way and 3-way ball valves: Versatility in flow control

In vacuum-based processes, the ability to control the flow of fluids or gases is crucial. Both 2-way and 3-way ball valves offer versatile solutions for flow control in vacuum systems.

2-way ball valves, as the name suggests, provide two flow paths: open and closed positions. This simplicity makes them suitable for applications where on/off control is required. They are often used in systems where the flow direction remains constant or needs to be shut off completely.

On the other hand, 3-way ball valves offer an additional flow path, allowing for more complex flow pattern configurations. These valves are commonly used when the flow needs to be diverted or combined between two different directions. By selecting the appropriate configuration of 2-way and 3-way ball valves, process engineers can tailor the flow control to their specific application requirements.

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Actuator assembly: Enabling automated control

To enhance the efficiency and control of ball valve vacuum systems, actuator assemblies play a crucial role. Actuators are devices that convert various forms of energy into mechanical motion, allowing for automated valve operation. There are different types of actuators available, including electric, pneumatic, and electromagnetic, each offering distinct advantages based on the application’s needs.

Electric actuators utilise electrical power to drive the valve’s opening and closing motion. They provide precise control and can be integrated into automation systems for remote operation. Pneumatics actuators, on the other hand, use compressed air or gas to actuate the valve. They are often preferred for their rapid response time and suitability for high-speed applications. Electromagnetic actuators employ electromagnetic force to control valve movement, offering accurate positioning and quick response.

By selecting the appropriate actuator assembly, you can achieve efficient and reliable automated control of their ball valve vacuum systems.

Features and applications

Ball valve vacuums offer several key features that make them suitable for a wide range of applications. Let’s explore some of these features and the corresponding applications where ball valve vacuums excel:

- Bi-directional leak-tight sealing: The ability to provide a leak-tight seal in both directions makes ball valve vacuums ideal for applications where containment and isolation of fluids or gases are critical. They find extensive use in the pharmaceutical, chemical, fine chemicals, API, food, cosmetics, minerals, metals, and various other industries.

- Wide range of operating conditions: Ball valve vacuums are designed to operate in extreme conditions, including high vacuum and sub-zero temperatures. Their robust construction and materials, such as stainless steel and corrosion-resistant alloys, allow them to withstand harsh environments encountered in semiconductor processing, medical applications, and industrial pick-and-place systems.

- Precise flow control: The unique design of ball valves enables precise flow control, allowing for accurate regulation of media in vacuum processes. They are particularly useful in applications that require uninterrupted flow or demand specific flow resistance for optimal performance.

- Integration into automation systems: Ball valve vacuums can be seamlessly integrated into automation systems, thanks to the availability of electric and pneumatic actuators. This feature enables remote control and automation, enhancing process efficiency and reducing manual labour.

Techno G’s segmented ball valve

Techno G is renowned for its high-performance segmented ball valves, specifically designed to handle solids. With their exceptional quality and innovative features, Techno G’s segmented ball valves offer numerous advantages for vacuum-based processes:

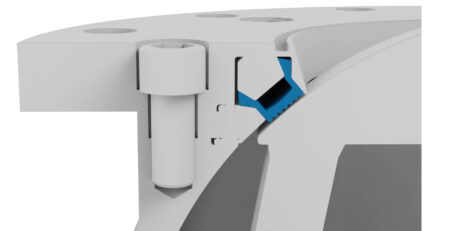

- Inflatable seal: Techno G’s segmented ball vacuum valves come with an inflatable seal, which ensures reliable sealing even when handling solids. This feature minimises the risk of leakage, preventing contamination and maintaining the integrity of the vacuum system.

- Solid handling capability: The segmented ball design of Techno G’s valves allows them to handle solid particles present in the media. This makes them ideal for processes that involve the transportation or containment of solid materials, such as minerals or food processing lines.

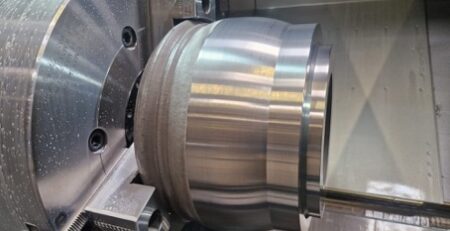

- Extended service life: The use of high-quality materials and precise engineering in Techno G’s segmented ball valves results in exceptional durability. They are designed to withstand continuous use, providing a long service life and reducing maintenance costs.

Ball valve material choices

At Techno-G, we understand the importance of material selection for ball valves to ensure their durability and performance in various environments, particularly in vacuum applications where corrosion resistance is paramount.

Stainless steel, known for its inherent corrosion resistance and ability to withstand aggressive and corrosive media, is a preferred choice for our vacuum ball valves. These valves are designed to endure the corrosive environments found in chemical processes, pharmaceutical manufacturing, and other industrial applications involving harsh chemicals.

Beyond stainless steel, we also utilise materials like carbon steel and alloys, depending on the specific requirements of the process. These materials not only provide excellent strength and durability but also offer resistance to corrosion and erosion.

At Techno-G, we prioritise the careful selection of appropriate materials for our ball valves in vacuum applications. This approach ensures the longevity and reliability of our systems while maintaining the integrity of the vacuum environment.

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

REACH OUT TO OUR EXPERT TEAM FOR YOUR INQUIRIES

Conclusion

In vacuum-based processes, the efficiency of operations is heavily reliant on the performance of the equipment used. Ball valve vacuum plays a important role in ensuring precise flow control, bi-directional leak-tight sealing, and reliable isolation. Techno G’s segmented ball valve, with its inflatable seal and exceptional quality for solids handling, stands out as a top choice for process engineers across various industries. By choosing Techno G’s ball segment valve, you can optimise the efficiency and reliability of their vacuum-based processes, ultimately leading to improved productivity and reduced downtime.